Sizing gauge for framework erection, framework and rapid framework erection method

A technology of measuring gauges and towers, which is applied in the connection of scaffolding, the connection of formwork/formwork/working frame, the support of building structures, etc., which can solve the difficulty of controlling the distance between columns, the inability to meet the speed requirements, and the slow speed of assembly and disassembly and other issues, to achieve the effect of avoiding size specification and adjustment work, improving erection efficiency and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

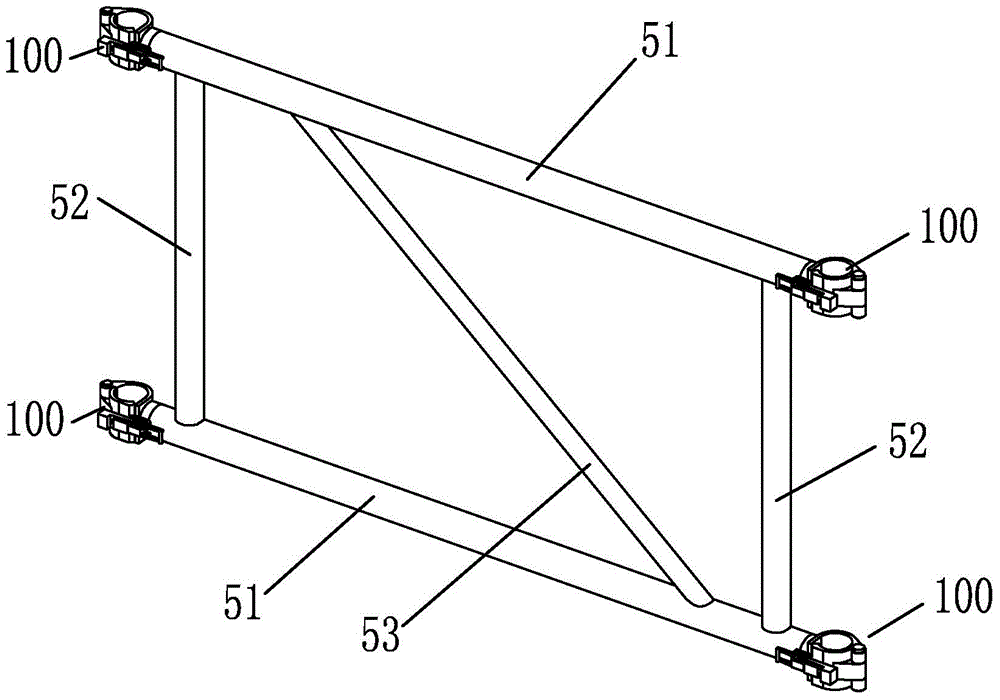

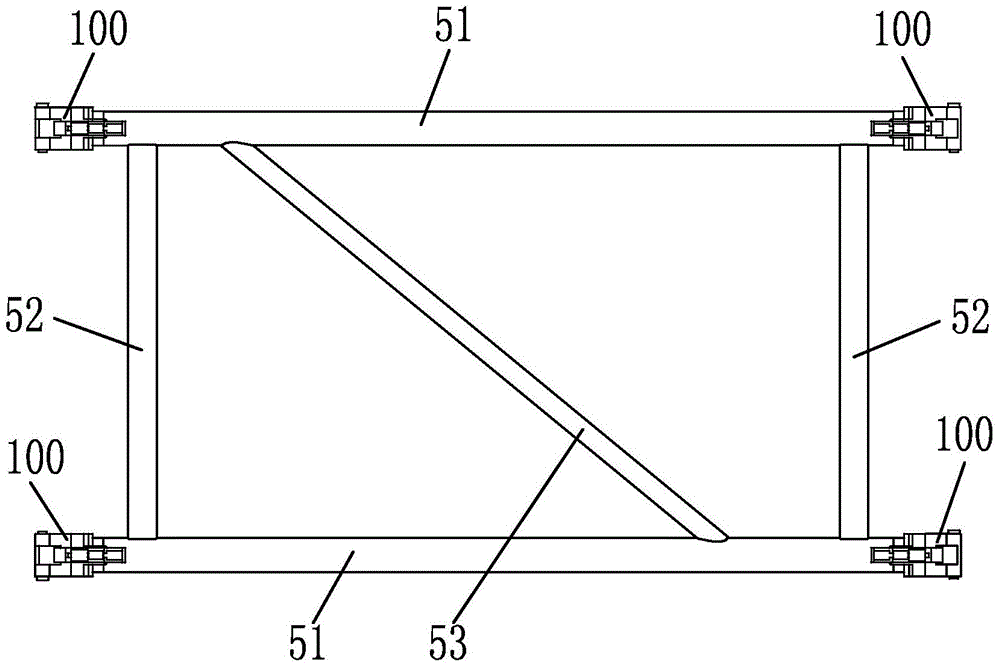

[0034] Example 1, see Figure 1-7 , a kind of measuring gauge for erecting a tower, comprising a measuring main body, the measuring main body is a rectangular frame structure, and the rectangular measuring main body comprises two fixed-length and equal-length horizontal tubes 51 and two equal-length vertical tubes 52, the two horizontal tubes 51 is welded into a rectangular frame by two vertical tubes 52, and a slanting tube 53 is welded between the two horizontal tubes 51. Use fastener 100.

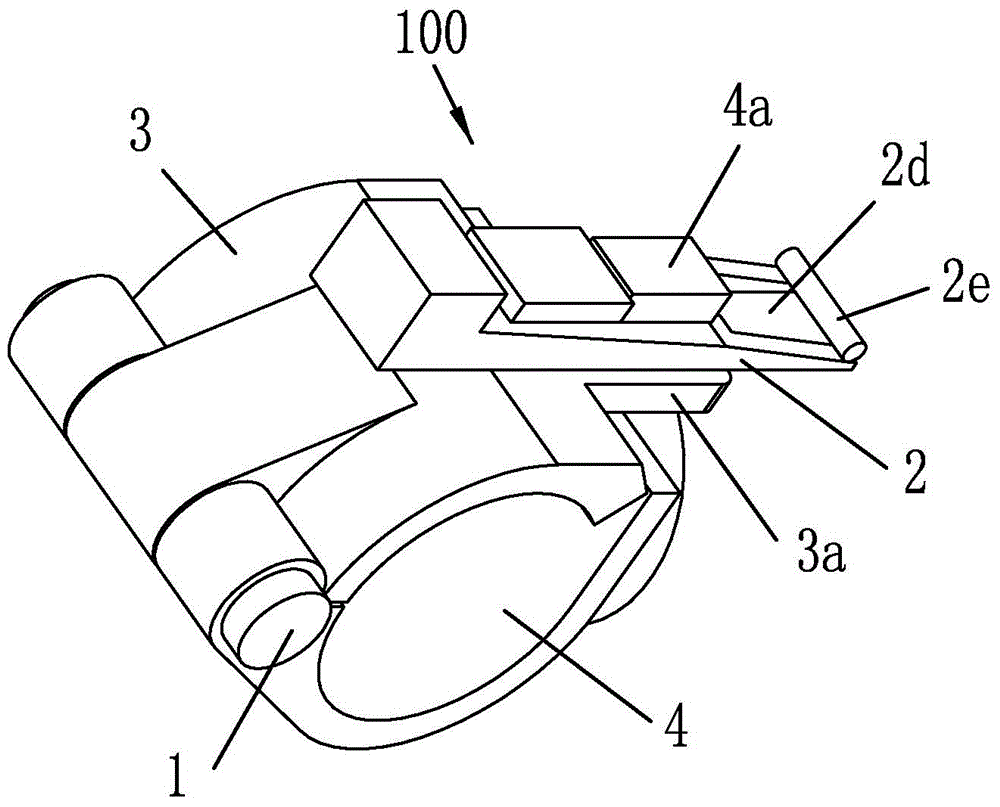

[0035] Among them, the fasteners for round steel pipes include two semicircular clamps hinged by a pin 1 and locked by a wedge 2. The free end of the first semicircular clamp 3 in the two semicircular clamps is along the direction of the outer circle section. A connecting ear 3a is extended, and a slot is formed in the middle part of the connecting ear 3a; the free end of the second semicircular clamp 4 in the two semicircular clamps forms a T-shaped clamp 4a along the direction of the ...

Embodiment 2

[0036] Example 2, see Figure 8 , a measuring gauge for erecting a tower, comprising a measuring body, the measuring body is composed of a steel pipe 5a, and two ends of the steel pipe 5a are respectively welded with a fastener 100 for a round steel pipe.

[0037] The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0038] Example 3, see Figure 9 , Figure 10 , a kind of sizing gauge for erecting a tower, comprising a sizing main body, the sizing main body is welded into a triangular command flag-shaped frame structure by steel pipes; the sizing main body includes a sizing main pipe 54, a vertical pipe 55, an inclined pipe 56 and A flag angle auxiliary pipe 57, the flag angle auxiliary pipe 57 is parallel to the fixed length main pipe 54, the flag angle auxiliary pipe 57 and the fixed length main pipe 54 are welded by the vertical pipe 55 and the inclined pipe 56, the outer end of the flag angle auxiliary pipe 57 and the fixed length Both ends of the main pipe 54 are welded with a fastener 100 for a round steel pipe.

[0039] The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com