Wire ring cabin linkage lock buckle mechanism of steel bar binding machine

A strapping machine and interlocking lock technology, which is applied in building construction, building material processing, construction, etc., can solve the problem of difficulty in ensuring the reliability and life of the machine, the increase in the failure rate of the steel bar strapping machine, and the lack of waterproof and dustproof Function and other issues, to achieve the effect of simple structure, reduced operation difficulty, stable and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

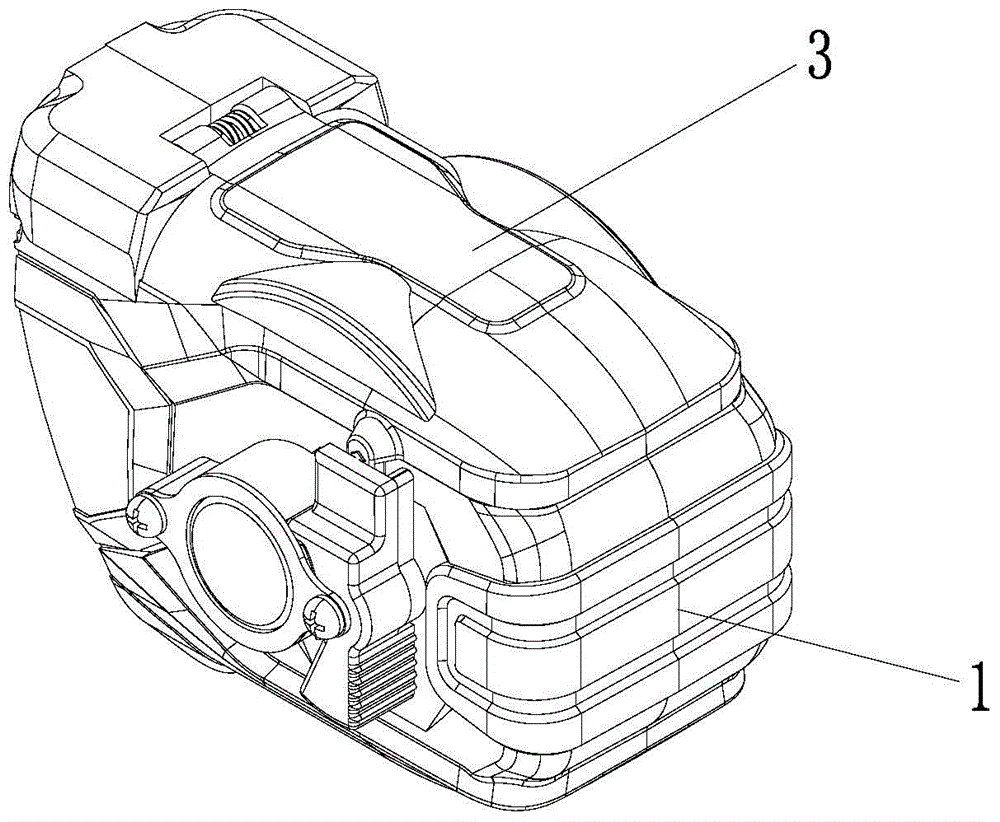

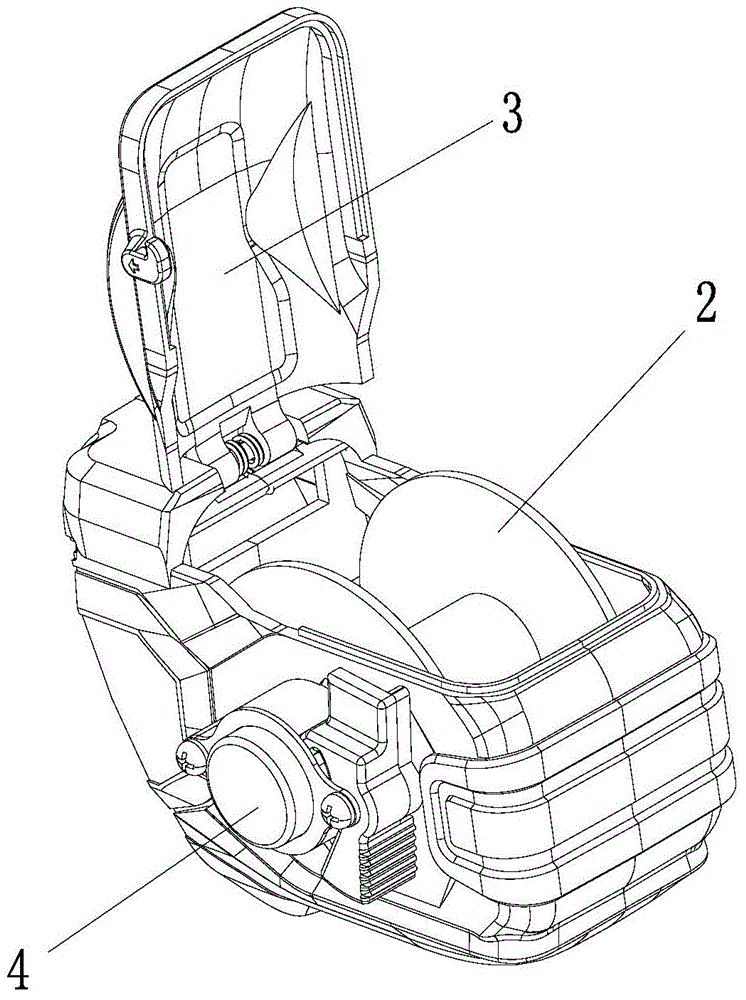

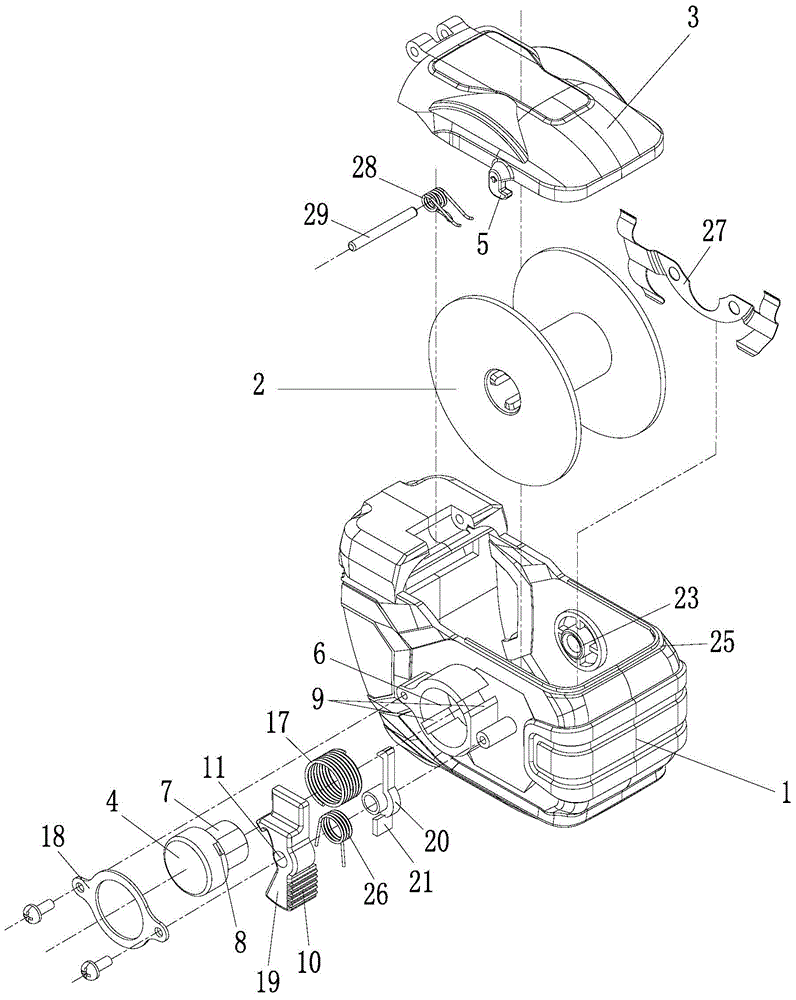

[0032] A wire loop bin linkage locking mechanism for a steel bar binding machine, comprising a wire hoop bin 1, a wire hoop 2, a wire hoop bin cover 3, a wire hoop positioning button 4, a torsion spring 26 and an unlock button, the wire hoop bin cover is hinged On the wire loop bin, the wire loop is placed in the wire loop bin, a hook 5 protrudes from one side of the wire loop bin cover, and a button cavity 6 is provided at a position corresponding to the hook in the wire loop bin, and the wire loop The positioning button axially protrudes with a movable wire ring positioning pin 7, and the radial direction of the wire ring positioning button shaft protrudes with a stopper 8, and a through hole 30 is opened in the button cavity, and the wire ring positioning button is arranged in the button cavity Among them, the active wire ring positioning pin is connected to the drum of the wire ring through the through hole, and the button cavity is provided with a guide groove 9 correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com