Method of directional pre-splitting blasting for roof cutting, pressure relief and gob-side roadway retention in coal mine mining roadway

A technology for mining tunnels and pre-split blasting, which is applied in ground mining, mining equipment, earth-moving drilling, etc., can solve the problems of difficult management, complex construction technology, and high filling costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

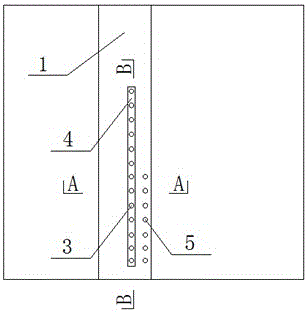

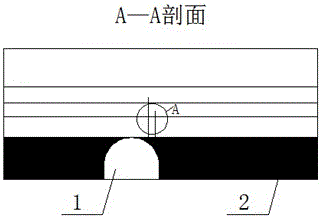

[0024] like Figure 1~5 As shown, a method of directional pre-splitting blasting, top-cutting, pressure relief and gob-side entry retaining in a coal mining roadway is illustrated by taking an arched mining roadway as an example. The middle height of the roadway section is 3.1m, and the bottom width is 5m. It includes the following steps:

[0025] ① Construct the anchor cables 3 along the direction at equal intervals in the reserved mining roadway 1;

[0026] According to step ①, the distance between the anchor cables 3 is 0.6-1.0m, preferably 0.8m, the diameter is not less than 21.6mm, and the length is 6-10m, preferably 8m.

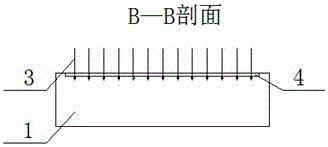

[0027] ② The construction W steel belt 4 connects the anchor cable 3 into one body for locking support;

[0028] According to step ②, the W steel strip 4 has a round hole, and the end of the anchor cable 3 passes through the round hole for locking. ~6m, preferably 5m, width 0.2~0.4m, preferably 0.3m, thickness 3~5mm, preferably 4mm.

[0029] ③ Constr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com