Unidirectional driving mechanism of bike tower base and flower drum main body

A one-way transmission, bicycle technology, applied in one-way clutches, mechanical equipment, clutches, etc., can solve problems such as large resistance and loud noise, and achieve the effect of reducing wear and inertial resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technology will be further described below in conjunction with the accompanying drawings.

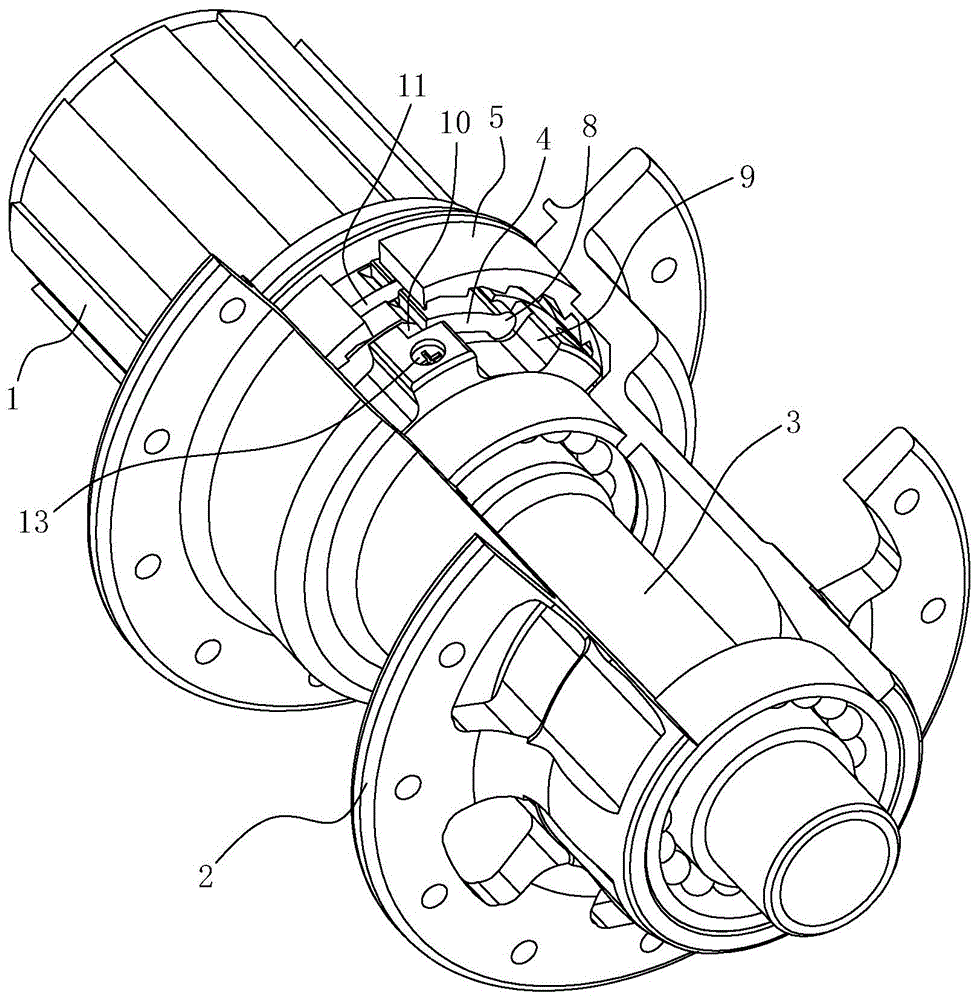

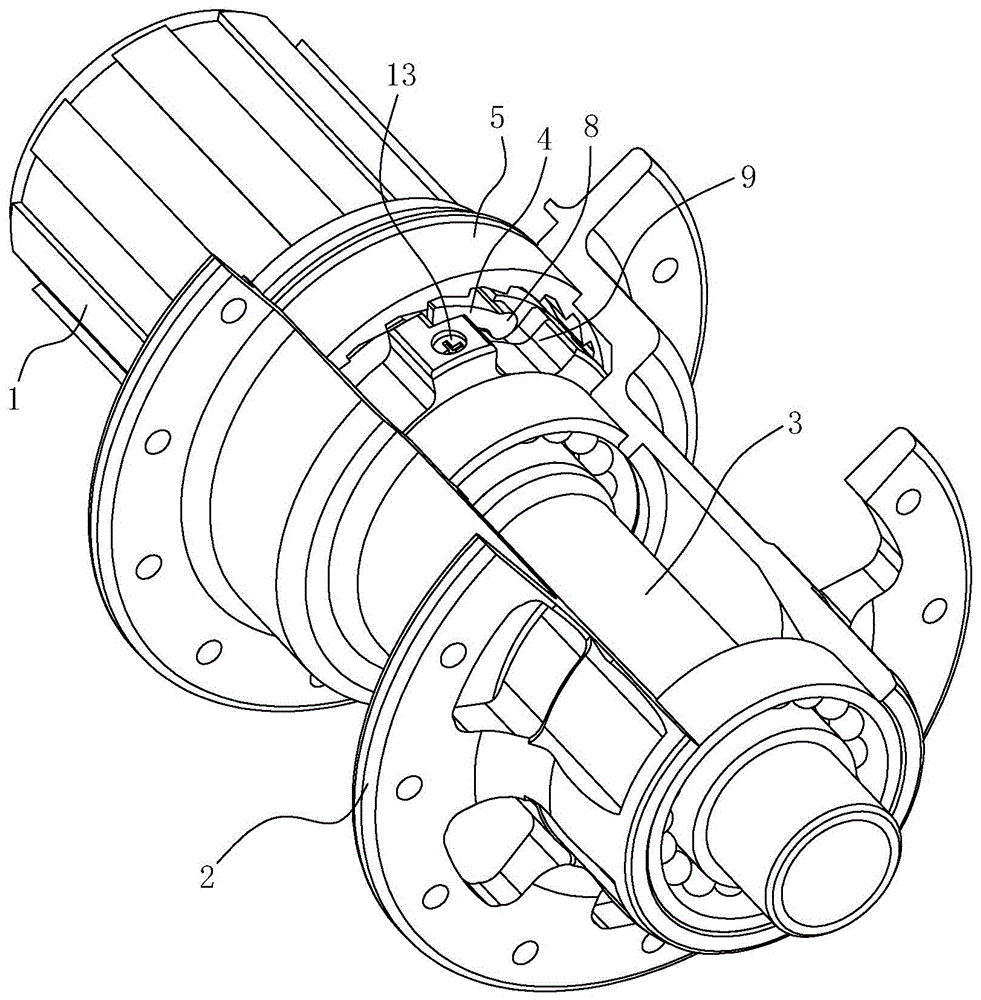

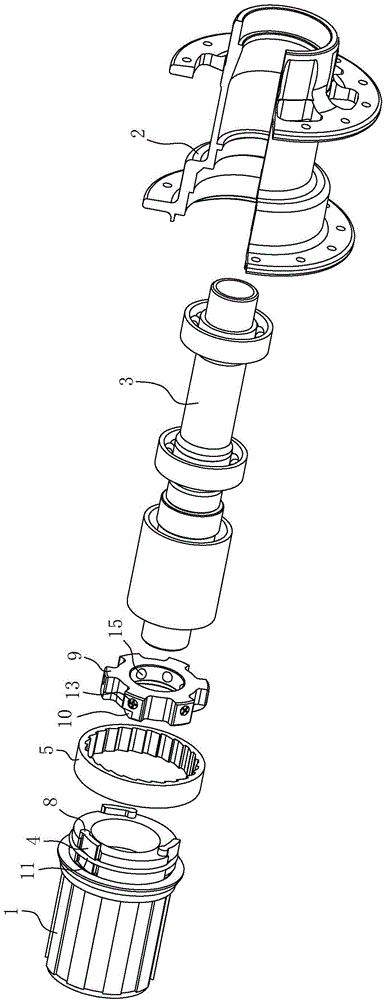

[0015] The one-way transmission mechanism between the freewheel base and the hub main body in this embodiment includes a freewheel base 1, a hub main body 2, a central shaft 3, claws 4, and an inner gear ring 5, and the freewheel base 1 and flower, 2 are passed through the central shaft 3, on the peripheral surface of the freewheel body 1 facing the hub main body 2, there is a first groove 6 that matches the shape of the claw 4, and one end of the first groove 6 is a cylindrical pit 7, The cylindrical pit 7 is a pit less than ninety degrees, and one end of the claw 4 is formed with a cylinder 8, which matches the cylindrical pit 7, and the cylinder 8 is embedded in the cylindrical pit 7, so that The claw 4 is movably bolted on the freewheel 1, and the claw 4 can rotate around its own cylinder 8. A middle ring 9 is arranged between the freewheel 1 and the hub main body 2 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com