Substrate separation method and device

A technology for a separation method and a separation device, which is applied in the field of separation methods and devices for solar cell substrates, can solve problems such as chip dropping or fragmentation, unfavorable continuous production, etc., and achieve the effects of reducing the fragmentation rate and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

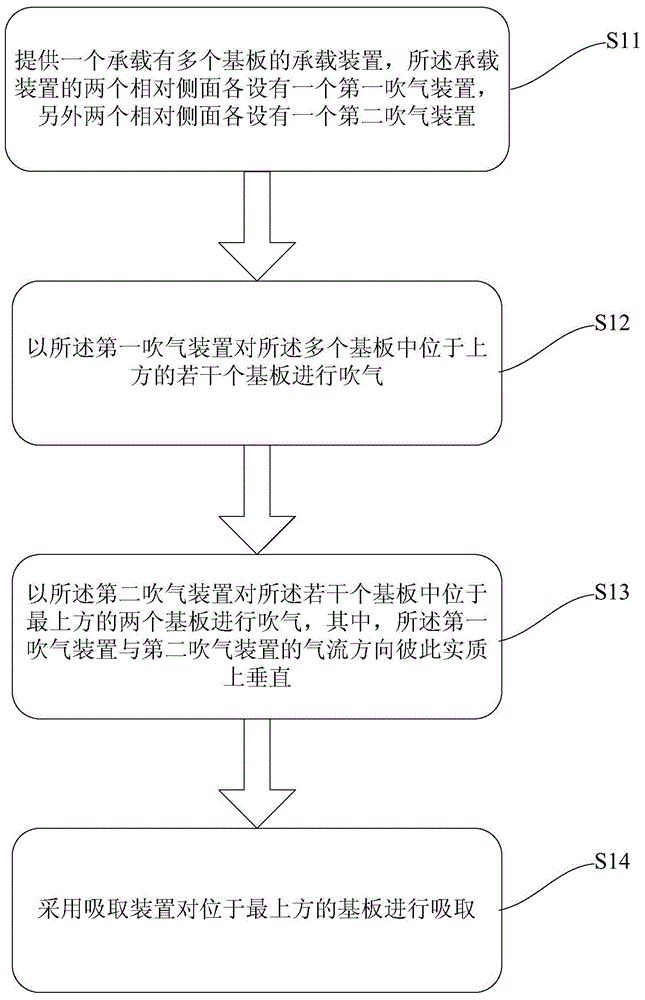

[0047] Example 1

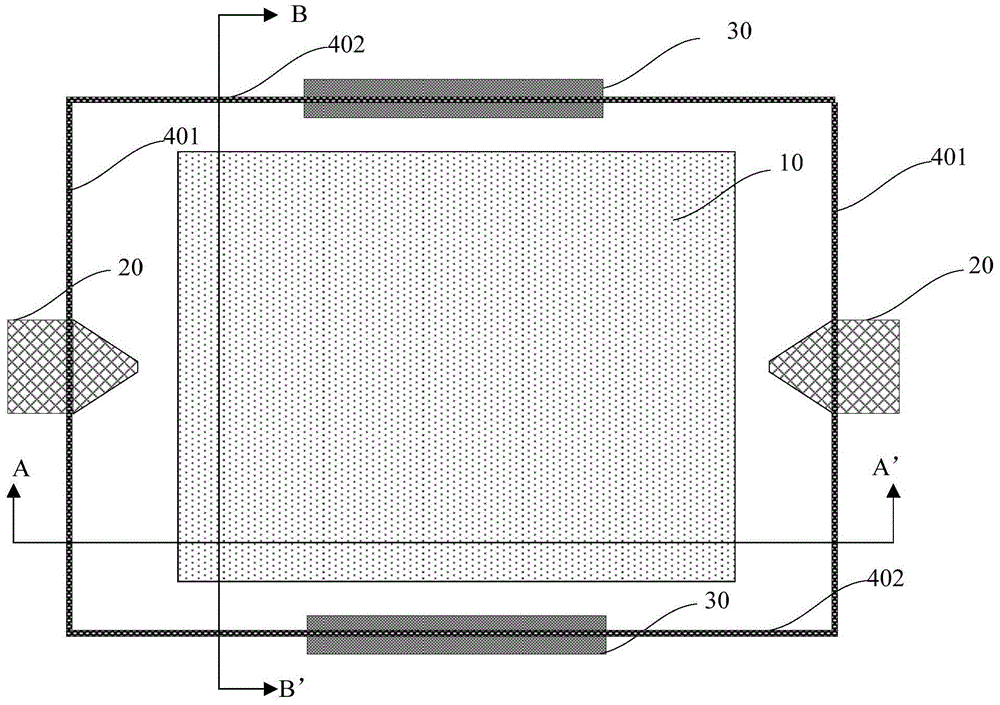

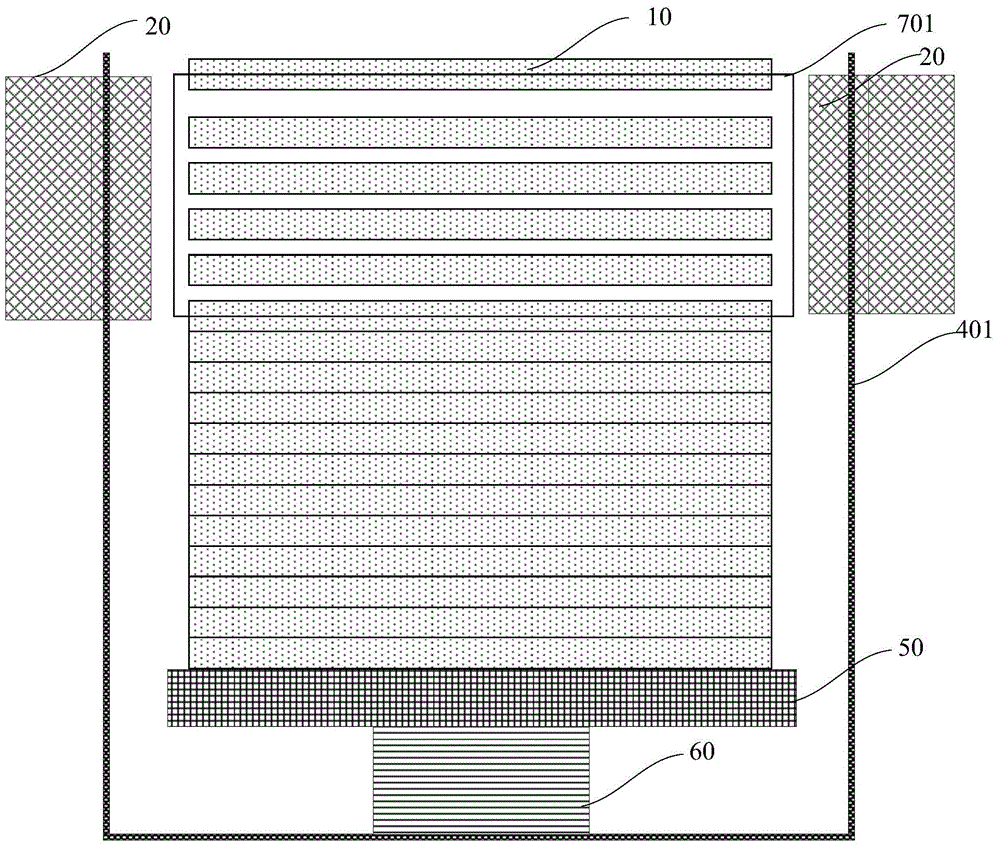

[0048] like Figure 2 to Figure 6 As shown, this embodiment provides a substrate separation device, including:

[0049] A carrying device 50 having two first side surfaces 401 opposite to each other and two second side surfaces 402 opposite to each other;

[0050] a push-up device 60 connected with the carrying device 50 to drive the carrying device 50 to move up and down;

[0051] a suction device (not shown), arranged above the carrying device 50;

[0052] two first air blowing devices 20, respectively disposed on the two first side surfaces 401; and

[0053] The two second air blowing devices 30 are respectively disposed on the two second side surfaces 402, wherein the air flow directions of the first air blowing device 20 and the second air blowing device 30 are substantially perpendicular to each other, that is, it may be At an angle of 90 degrees to each other, or an angle of about 89 degrees or 91 degrees close to the 90-degree angle.

[0054] li...

Example Embodiment

[0069] Example 2

[0070] like Figures 2 to 5 and Figure 7 As shown, this embodiment provides a substrate separation device, the basic structure of which is the same as that of the first embodiment, wherein each of the second air blowing devices 30 has at least one elongated second air outlet 301, and the elongated second air outlet The two air outlets 301 are arranged in a horizontal direction.

[0071] like Figures 1 to 5 and Figure 7 As shown, this embodiment also provides a method for separating substrates, the basic steps of which are the same as those in Embodiment 1, wherein each of the second air blowing devices 30 has at least one elongated second air outlet 301, and the elongated second air outlet The second air outlet holes 301 are arranged in a horizontal direction.

[0072] It should be noted that, in this embodiment, the number of the elongated second air outlet 301 is one, but in other embodiments, the number can be arbitrarily changed according to requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com