System and method for linkage of electric power tunnel inspection robot and fire extinguishing system

A technology for inspection robots and power tunnels, applied in the field of fire protection of power tunnels, can solve problems such as low fire extinguishing efficiency, unfavorable personnel safety, long distances, etc., and achieve the effects of ensuring tunnel environmental safety, reducing accident risks, and accurate information.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

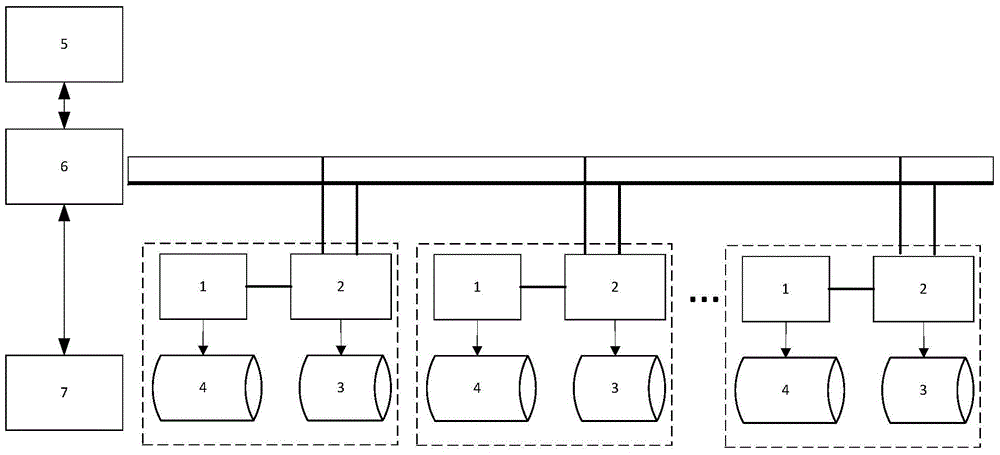

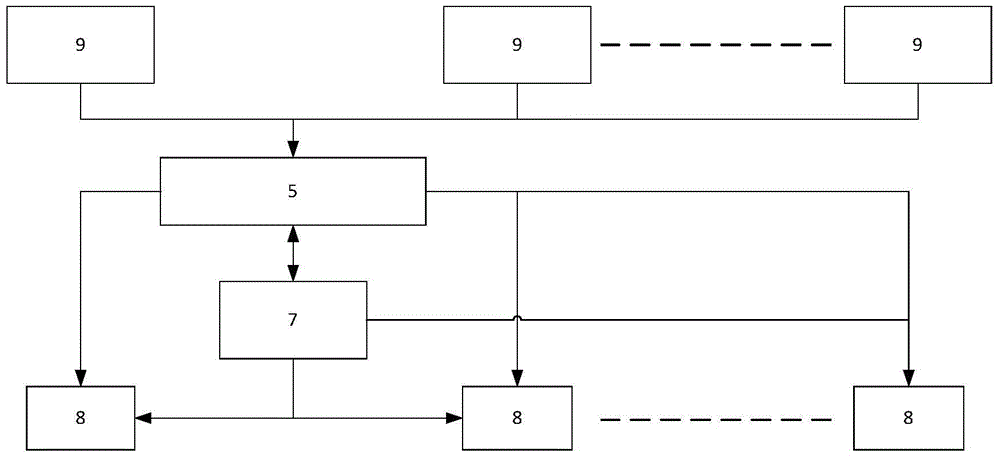

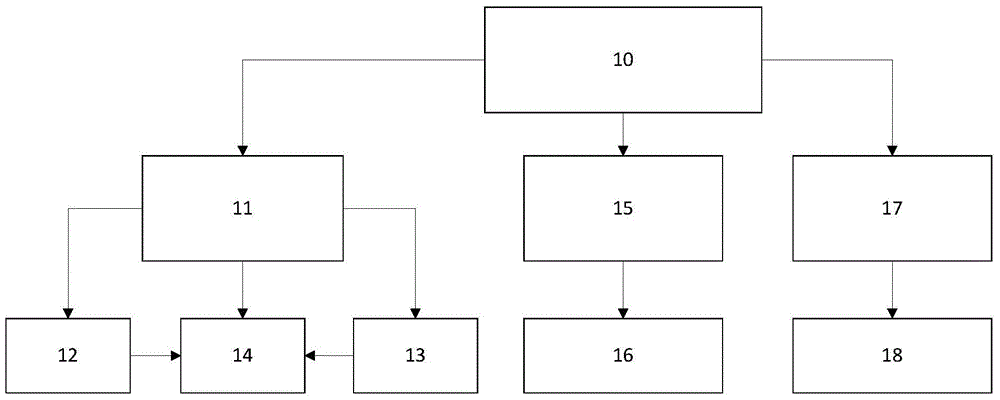

[0032] like figure 1 As shown, add a fire door inside the tunnel or modify the existing fire door; install a fire door control box near each fire door, and the fire control box contains a local fire door controller 2 and a local backup power supply 3. Install door opening and closing device 1 and electric suction lock 4 on it, and each intelligent fire door control system has two power supply methods, remote power supply and local backup power supply 3, to ensure the smooth passage of on-site robots 7 or staff; all fire door control systems The device 2 is connected to the fire door control cabinet 6 through the field bus. The fire door control cabinet 6 can manage the fire doors of at least 32 fire compartments. The control platform is the REALTIME platform 5, which is connected to the fire door control cabinet 6 through industrial Ethernet. Realize t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com