Device for comminuting solids or suspensions containing solids and method for starting a comminuting process of a milling device

A technology of solid materials and phase components, applied in grain processing and other directions, can solve problems such as large loads, and achieve the effects of low power, reduced size, and low purchase cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

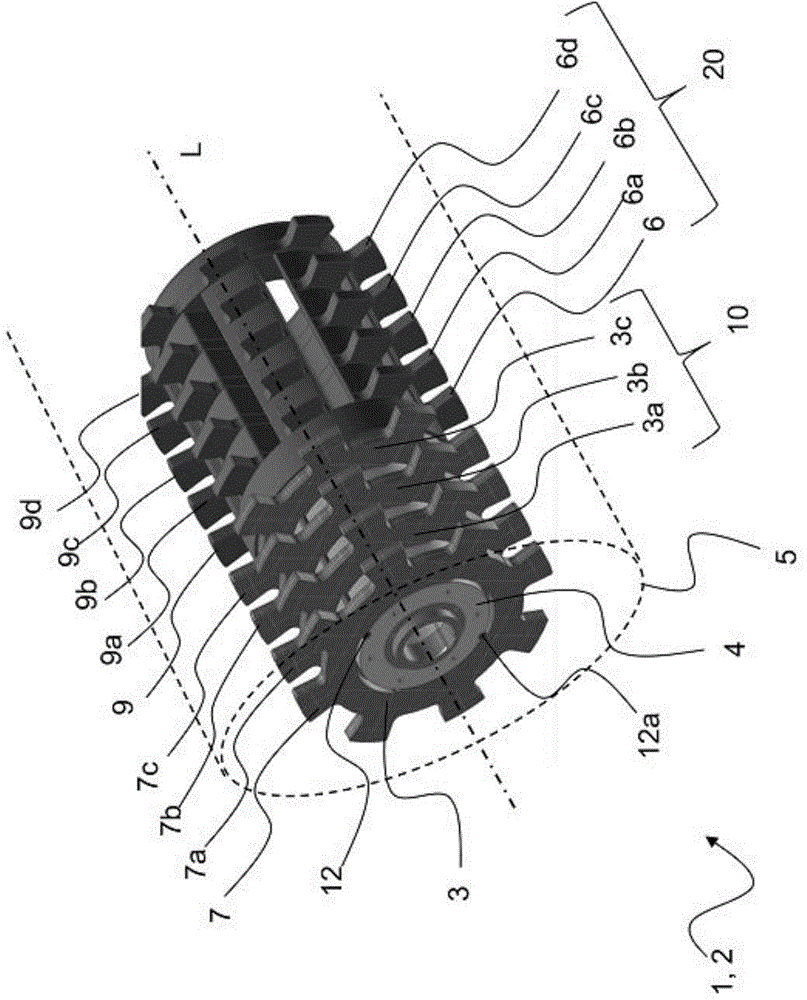

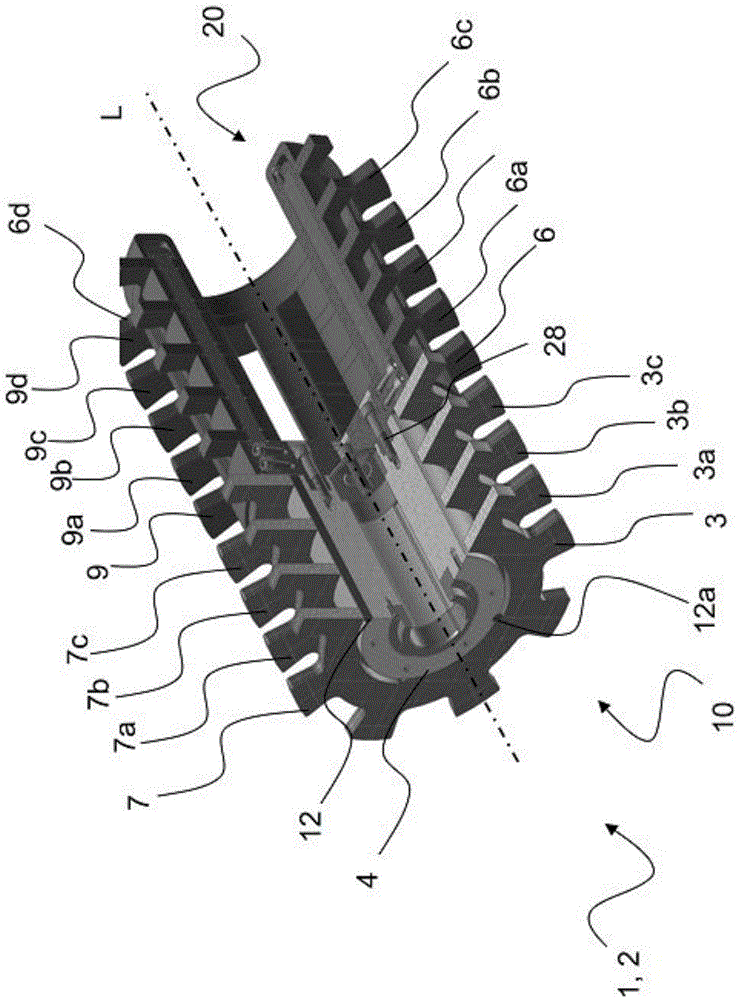

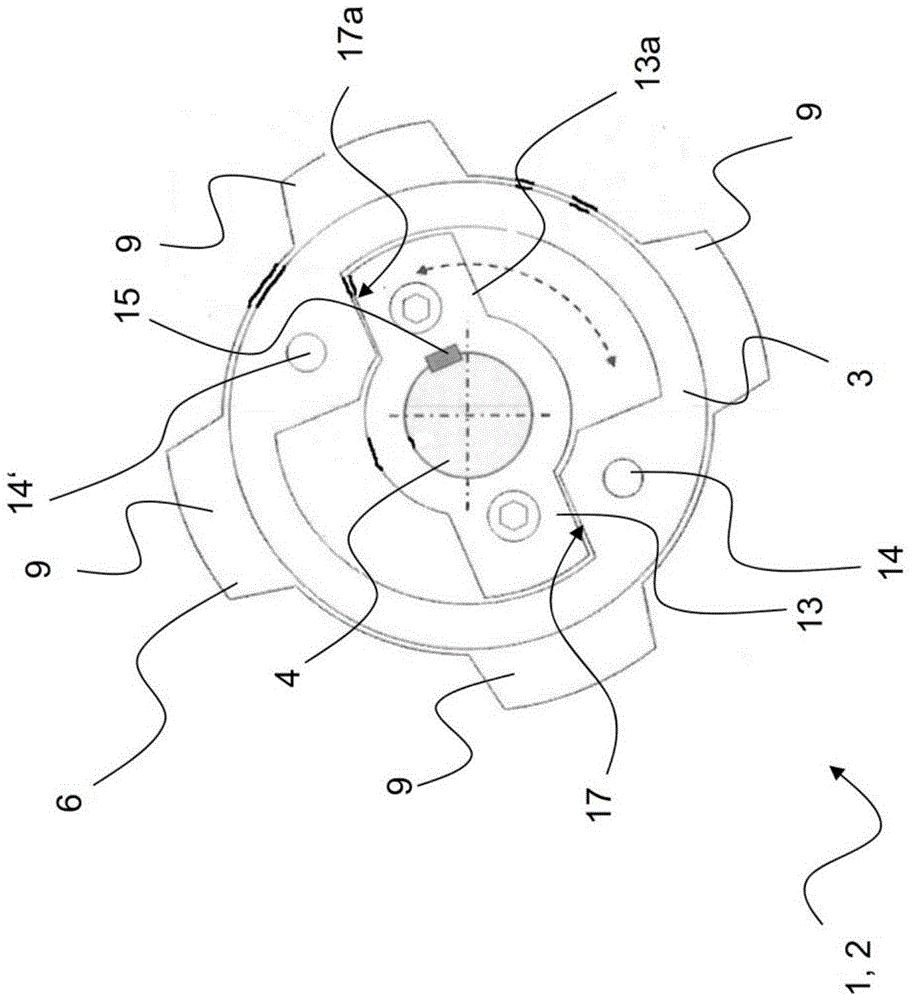

[0080] figure 1 A schematic perspective view of an embodiment of the device 1 according to the invention is shown. The device 1 is provided for comminutively processing solid materials or suspensions with solid phase components and is designed in the present invention as an agitator ball mill 2 . The solid material comminuted by means of the device 1 can be composed of minerals, for example.

[0081] A cylindrical grinding container 5 , which is formed as a component of the device 1 , is shown in phantom lines, in which the various grinding materials as well as grinding balls (not shown) are arranged. The grinding container 5 is mounted immovably or fixedly and may optionally have a figure 1 The bottom of the container and the lid of the container are not visible in the container.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com