Compound equipment of tourmaline-loaded nanometer TiO2 compound fabrics

A technology of tourmaline-loaded and composite fabrics, which is applied in the field of textile fabric manufacturing. It can solve the problems of reducing the functionality of TiO, reducing the contact area of tourmaline-loaded, and the composite surface is prone to peeling, and achieves the effect of increasing the air contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

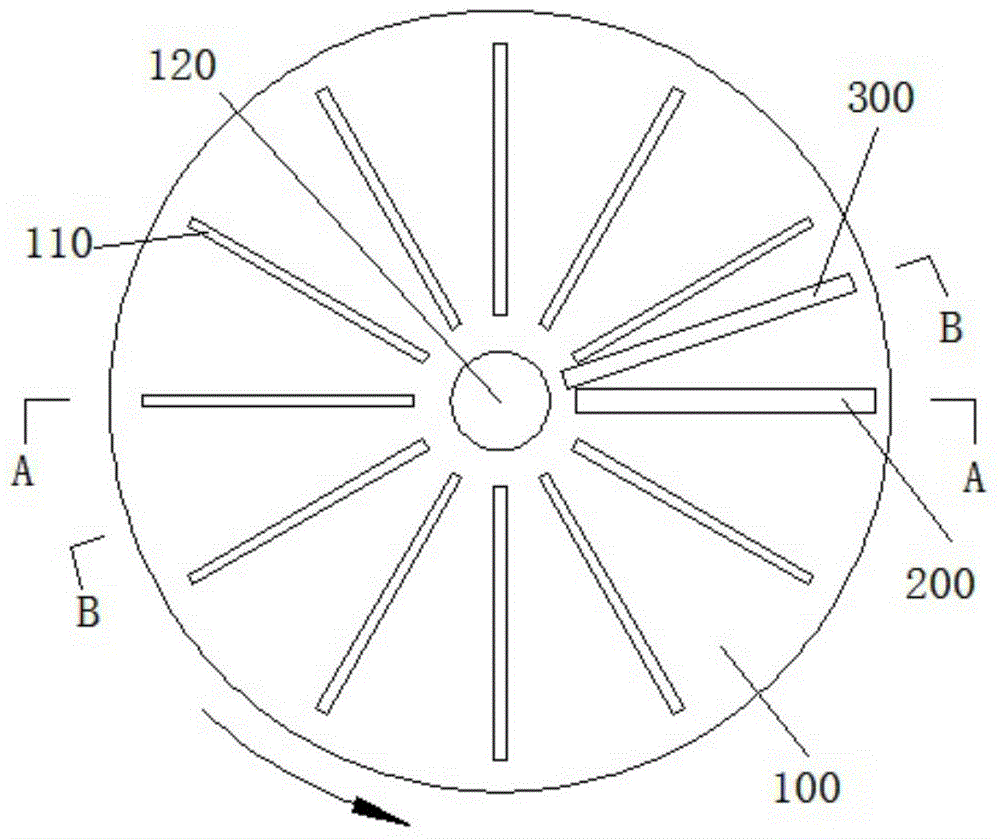

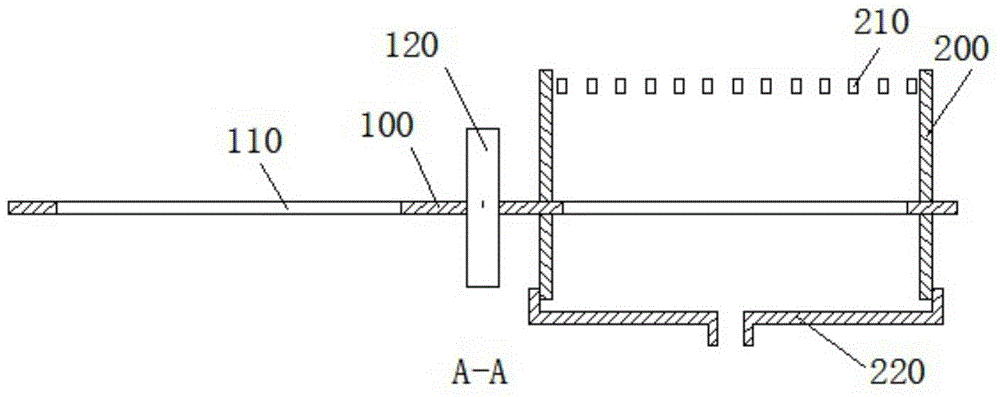

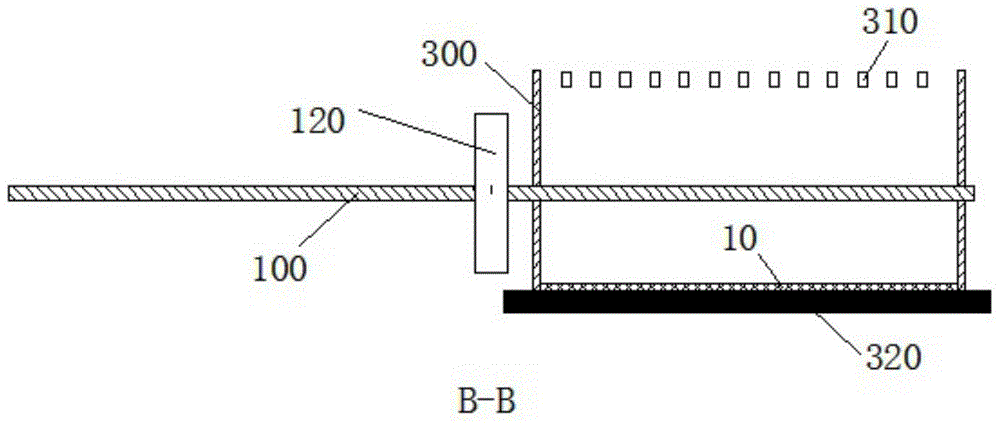

[0015] In this example, see figure 1 , figure 2 and image 3 , the tourmaline-loaded nano-TiO 2 The composite device of the composite fabric comprises a vertically arranged glue channel 200 for spraying adhesive and a vertically arranged, sprayed tourmaline-loaded nano-TiO 2 The spray channel 300 of the powder, the nozzle 210 of the glue channel 200 and the nozzle 310 of the spray channel 300 are all arranged on the top, and the glue channel 200 and the spray channel 210 have a slit in the same plane, and the cut A turntable 100 that passes through the slit is fitted in the slit, and radial openings 110 are evenly distributed along the axis on the turntable 100 . Correspondingly, a guide roller 320 cooperating with the outlet is provided at the lower outlet of the spray channel 210 , and the base cloth 10 is arranged on the guide roller 320 .

[0016] The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com