Thread detection device and tapping and detecting production line with thread detection device

A technology of inner wire teeth and inspection devices, which is applied in the direction of measuring/indicating equipment, metal processing equipment, cleaning methods and utensils, etc., can solve problems such as low work efficiency, complicated mechanism, difficulty in meeting high-speed production steps, etc., and achieve reduction in the number of workers , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

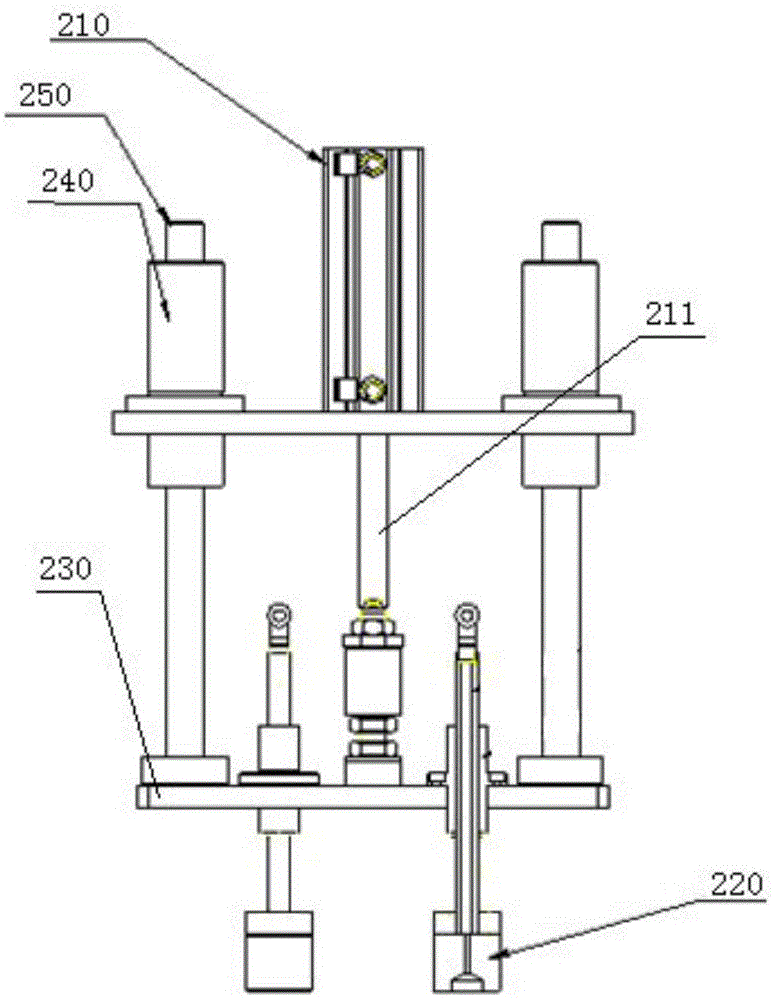

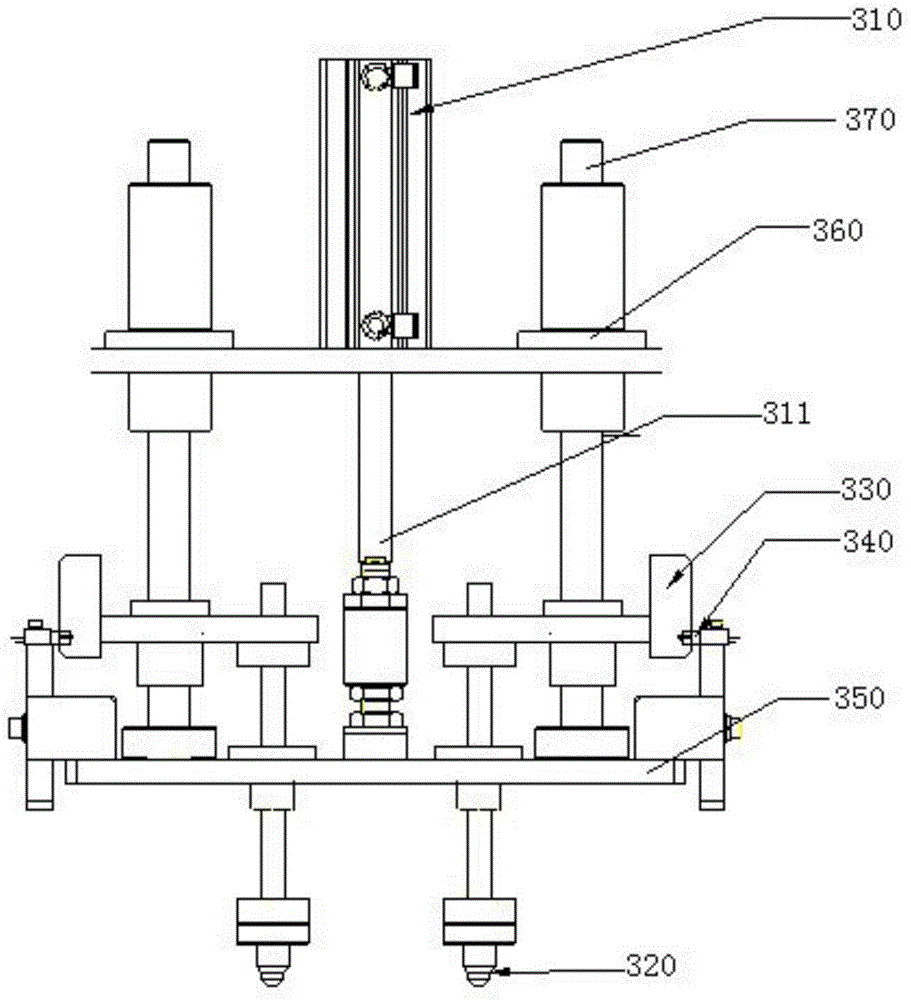

[0023] In order to avoid repetition, the thread inspection mechanism of the present invention will not be introduced separately, but introduced together in the automatic tapping and detection production line of the present invention.

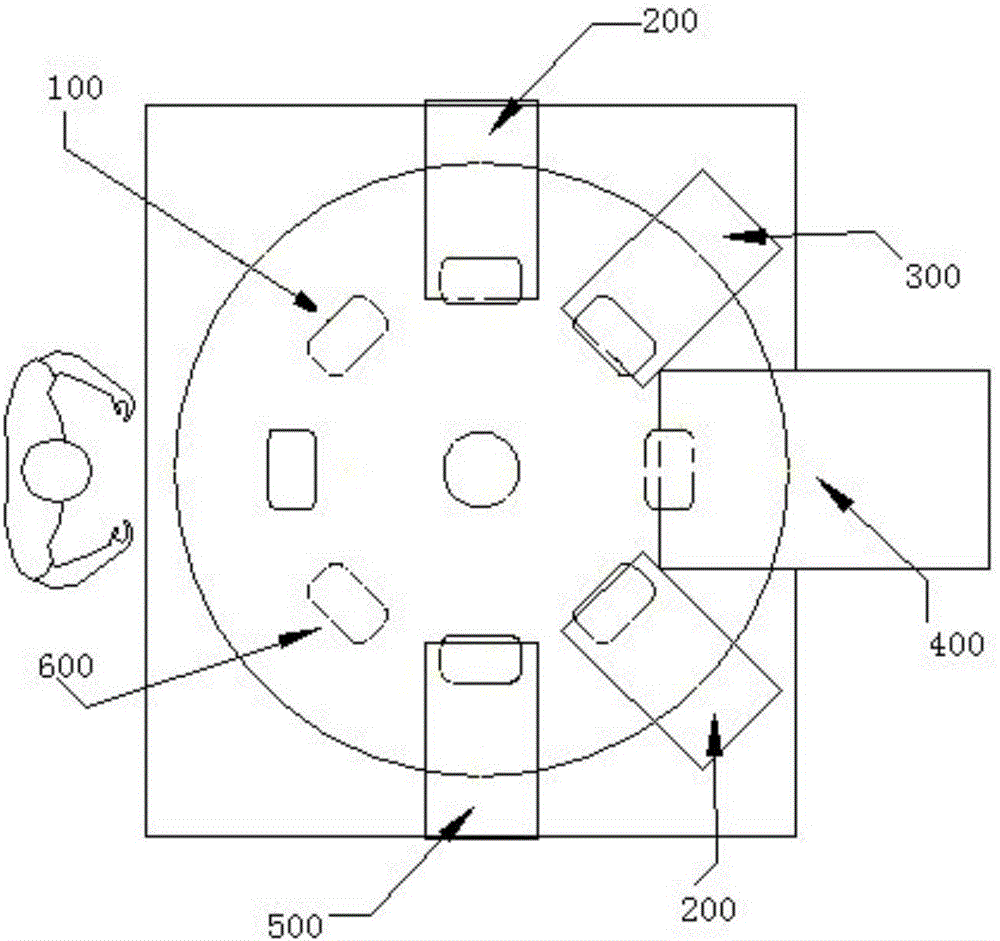

[0024]The fully automatic tapping and testing production line includes three parts: control system, operating system and mechanical operation structure. The control system controls the work of each component of the operating system, adopts PLC control cabinets, etc., and the operating system communicates with man-machine information, inputs human instructions, and transmits them to the control system; at the same time, it receives information feedback from the mechanical operating structure, which is convenient for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com