Walking mechanism and walking method of crawling robot

A crawling robot and walking mechanism technology, applied in the direction of motor vehicles, aircraft assembly, aircraft parts, etc., to achieve the effect of large volume, high rigidity performance, and structural weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

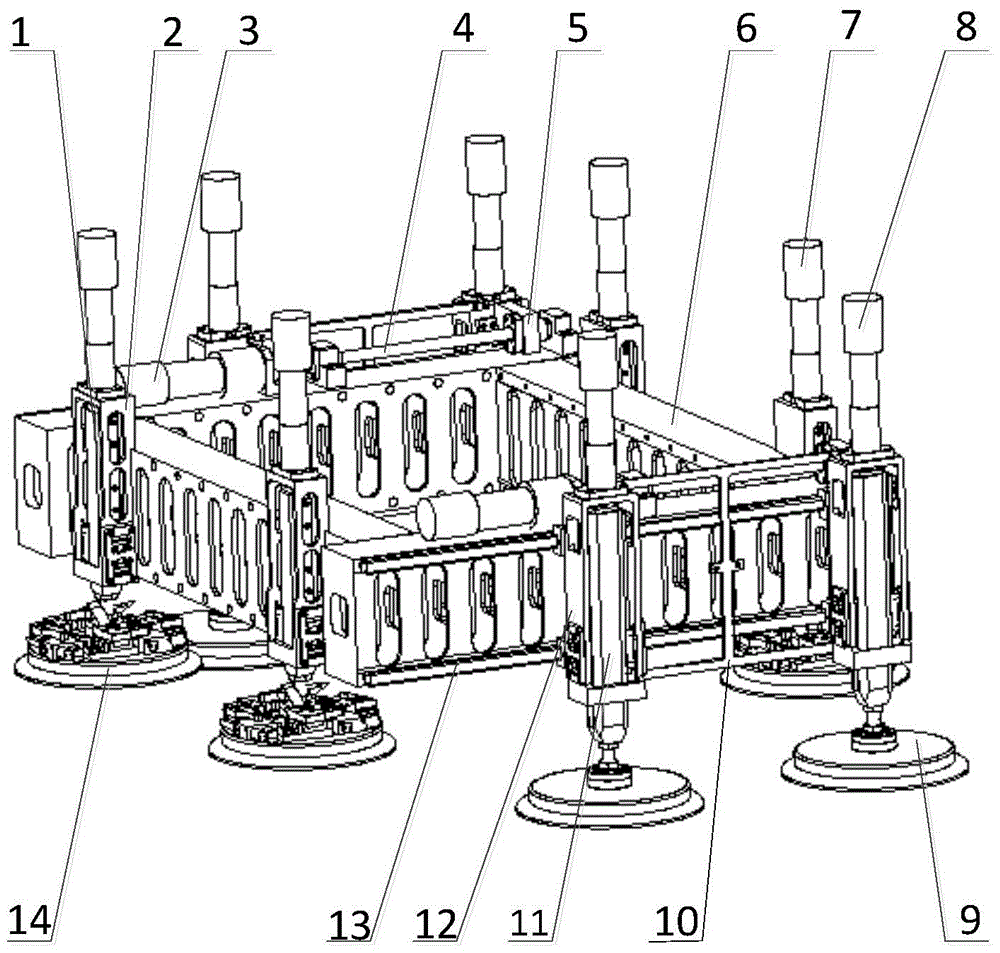

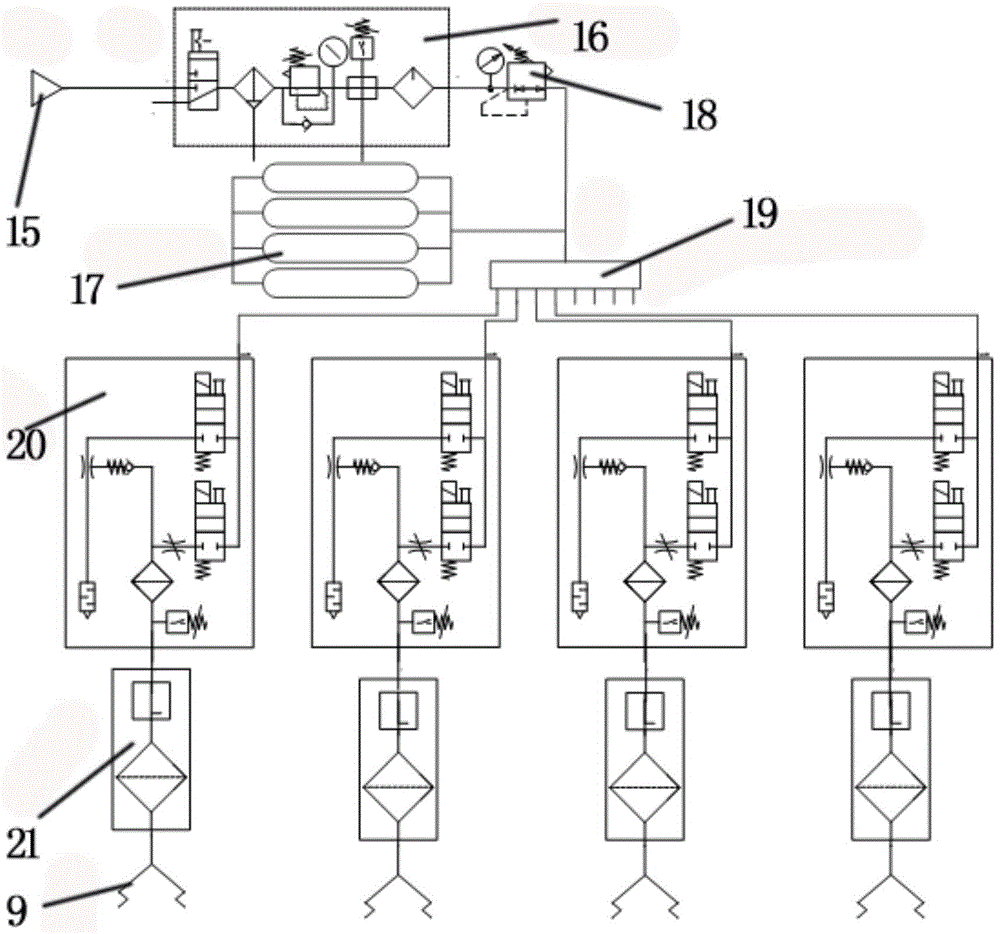

[0038] Such as figure 1, a walking mechanism of a crawling robot, comprising a moving frame 6, outer legs, and inner legs. The moving frame 6 is rectangular in shape. A plurality of outer legs are symmetrically installed on two symmetrical sides of the moving frame 6, and a plurality of inner legs are symmetrically installed on the other two sides. Leg comprises outer leg frame 12 and telescopic leg 11 placed in outer leg frame 12, inner leg includes inner leg frame 2 and telescopic leg 1 placed in inner leg frame, outer leg suction cup 9 is installed at the bottom of outer leg, inner leg bottom The inner leg suction cup 14 is installed; the telescopic leg 11 of the outer leg is connected with the mobile frame 6, and the mobile frame 6 rises and falls with the lifting of the telescopic leg 11 of the outer leg, and the inner leg frame 2 is rigidly connected with the mobile frame 6, and the inner leg frame 2 moves with the The frame 6 is lifted and lowered; the outer leg frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com