Automatic grouting type float collar

An automatic grouting and floating hoop technology, applied in wellbore/well components, earthwork drilling, sealing/packing, etc., can solve the problems of reducing the return speed, prolonging the construction time of casing running, and having no automatic grouting function. Reduce impact force, speed up casing running, and overcome time-consuming and labor-intensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

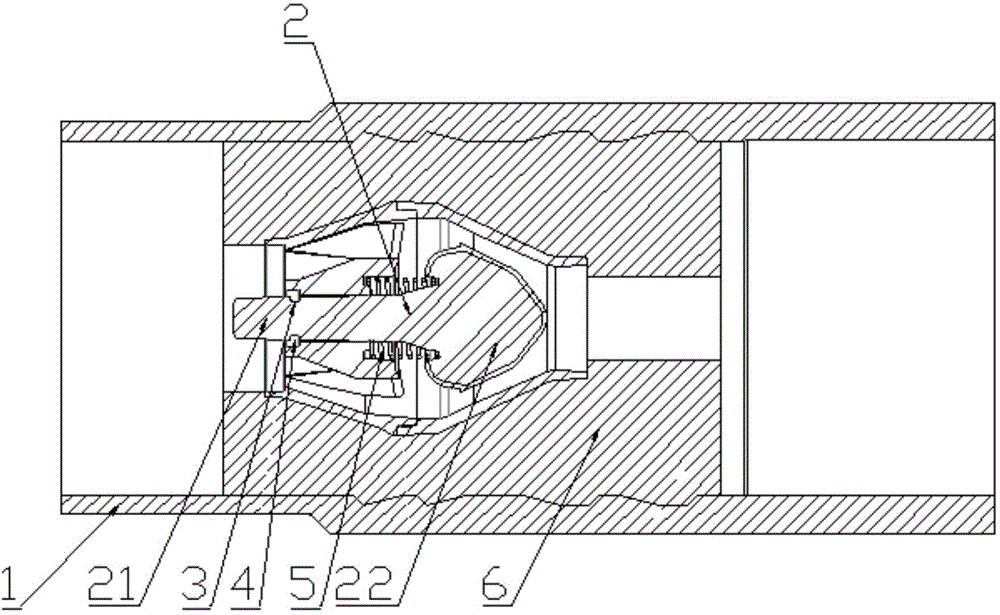

[0017] In addition, an automatic grouting floating hoop mentioned in the embodiment of the present invention includes a body 1, a valve body 2, a ball 4, a spring 5 and a cement body 6, the body 1 is cylindrical, and the upper part of the body 1 There is a female thread connected with the casing, and the lower part of the body 1 is provided with a male thread connected with the casing. A cement body 6 is provided between the female thread and the male thread. The cement body 6 is cylindrical, and the cement body 6 Fixed inside the body 1, a valve body 2 is arranged in the middle of the cement body 6, and the valve body 2 is composed of a valve head 22 and a valve stem 21, and a groove 3 is provided at the lower end of the valve stem 21, and the groove 3 A ball 4 is arranged inside, and a spring 5 is set betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com