multi-hole drill

A multi-hole drill and equipment technology, applied in drilling/drilling equipment, boring/drilling, metal processing equipment, etc., can solve problems such as drill or tap breakage, inconsistent screw direction of threaded holes, personal injury to operators, etc. , to avoid the drill bit breaking or popping out, the steering and rotation speed are consistent, and the effect of avoiding industrial accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

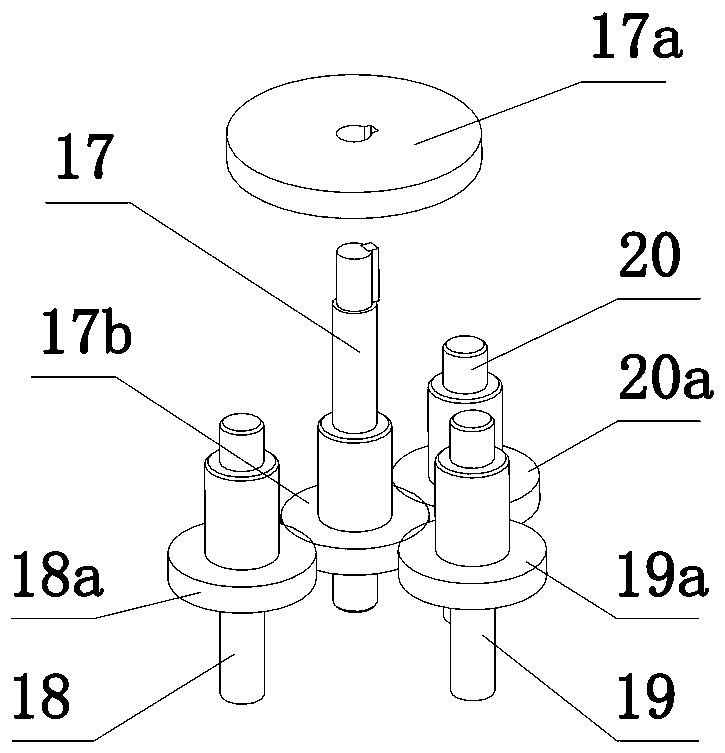

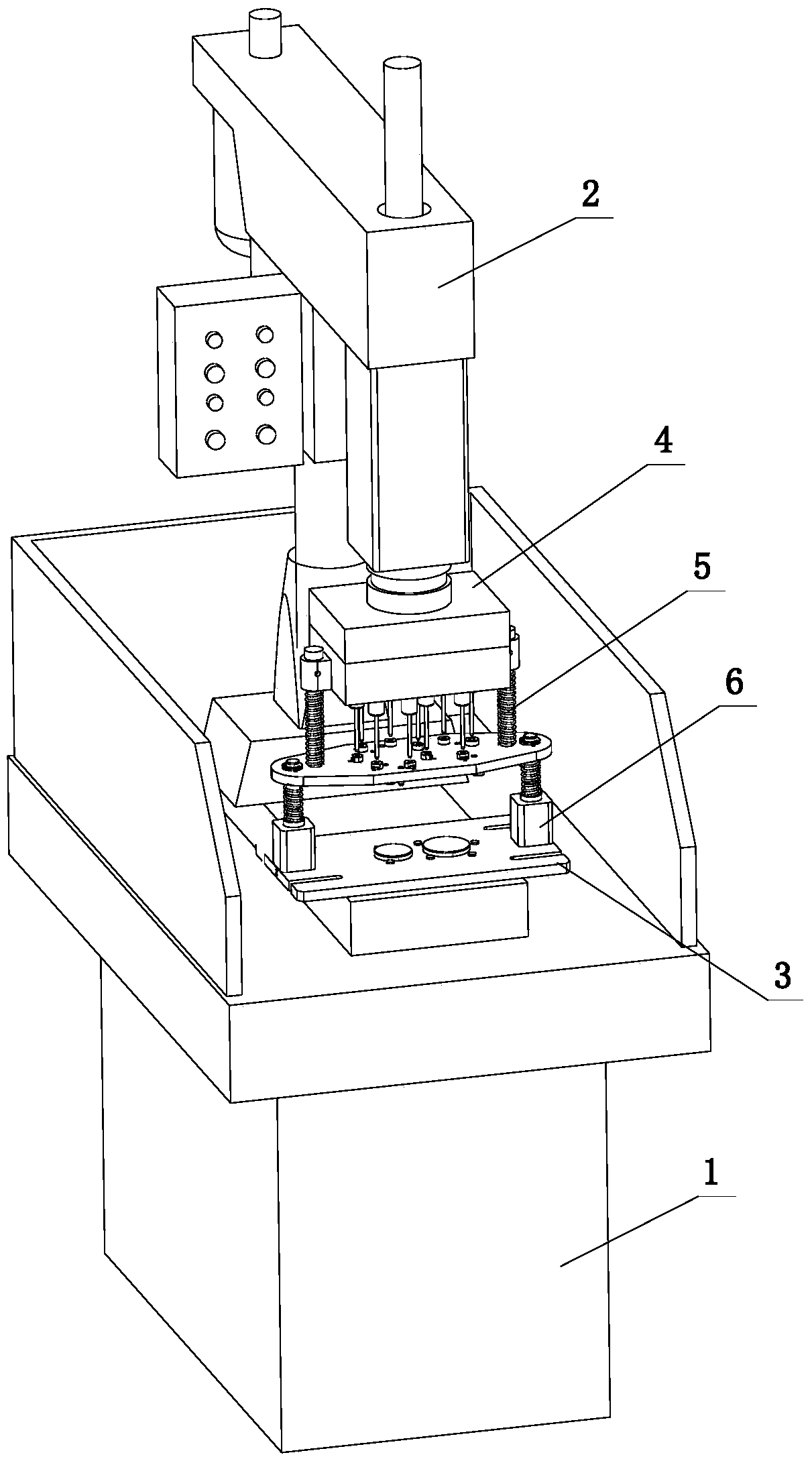

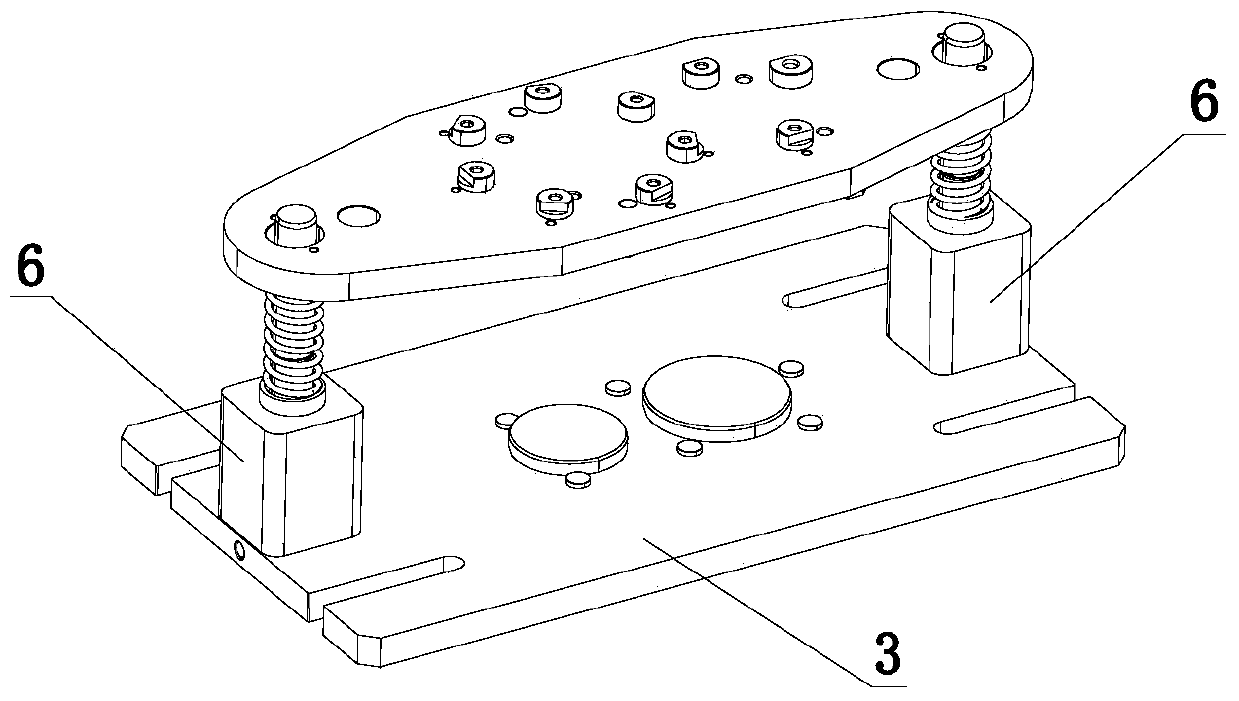

[0024] refer to Figure 1 to Figure 5 A kind of multi-hole drilling equipment shown comprises a bed 1 and a radial drilling machine 2 and a multi-hole synchronous tooling 3 installed on the bed 1, a gear box 4 is installed on the radial drilling machine 2, and the gear box 4 The input end is connected with the output shaft of the radial drilling machine 2, and the output end of the gear box 4 is provided with ten drill bit mounting seats 7; the multi-hole synchronous tooling 3 is installed directly below the gear box 4, and the The gear box 4 is connected with the porous synchronous tooling 3 through the guide column 5; the porous synchronous tooling 3 is provided with ten drilling stations, and the ten drilling stations are connected with the ten drill bit mounting seats 7. One to one correspondence.

[0025] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com