A profile laser cutting feeding mechanism with replaceable profile clamping wheel

A feeding mechanism and laser cutting technology, applied in laser welding equipment, welding/cutting auxiliary equipment, welding/welding/cutting items, etc., to achieve the effect of reasonable structure setting, good clamping effect, and high precision of synchronous rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is specifically described below by the embodiment, only for further illustrating the present invention, can not be interpreted as the limitation of protection scope of the present invention, the technical engineer of this field can make some non-essential improvements and improvements to the present invention according to the content of the above-mentioned invention Adjustment.

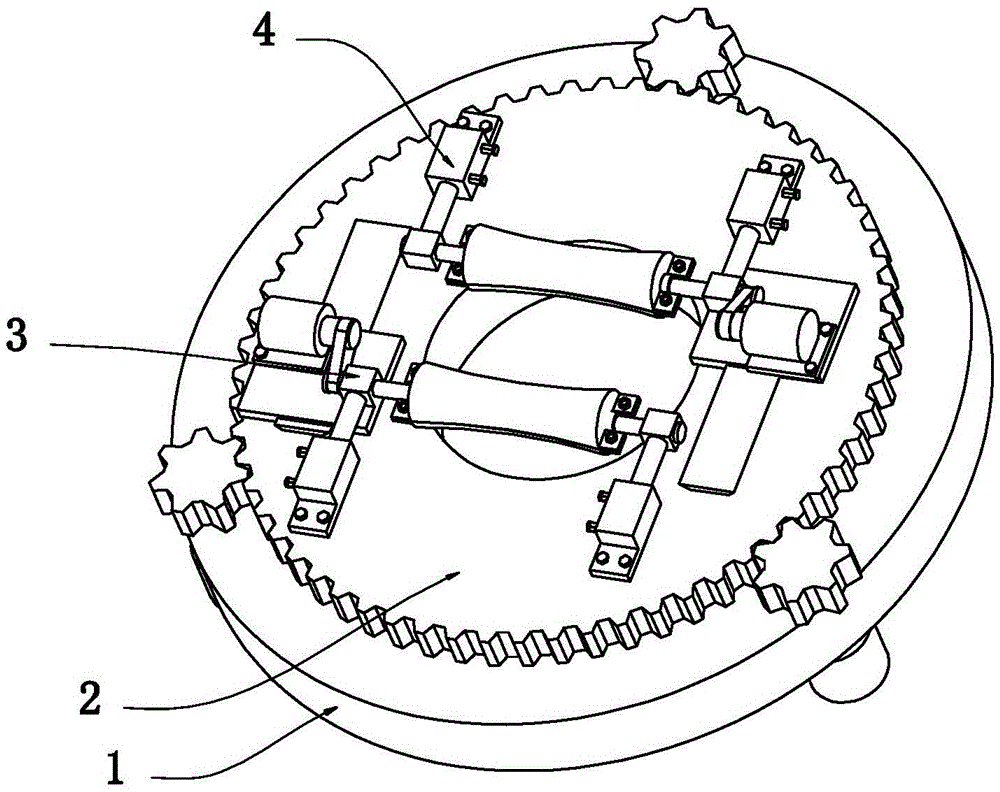

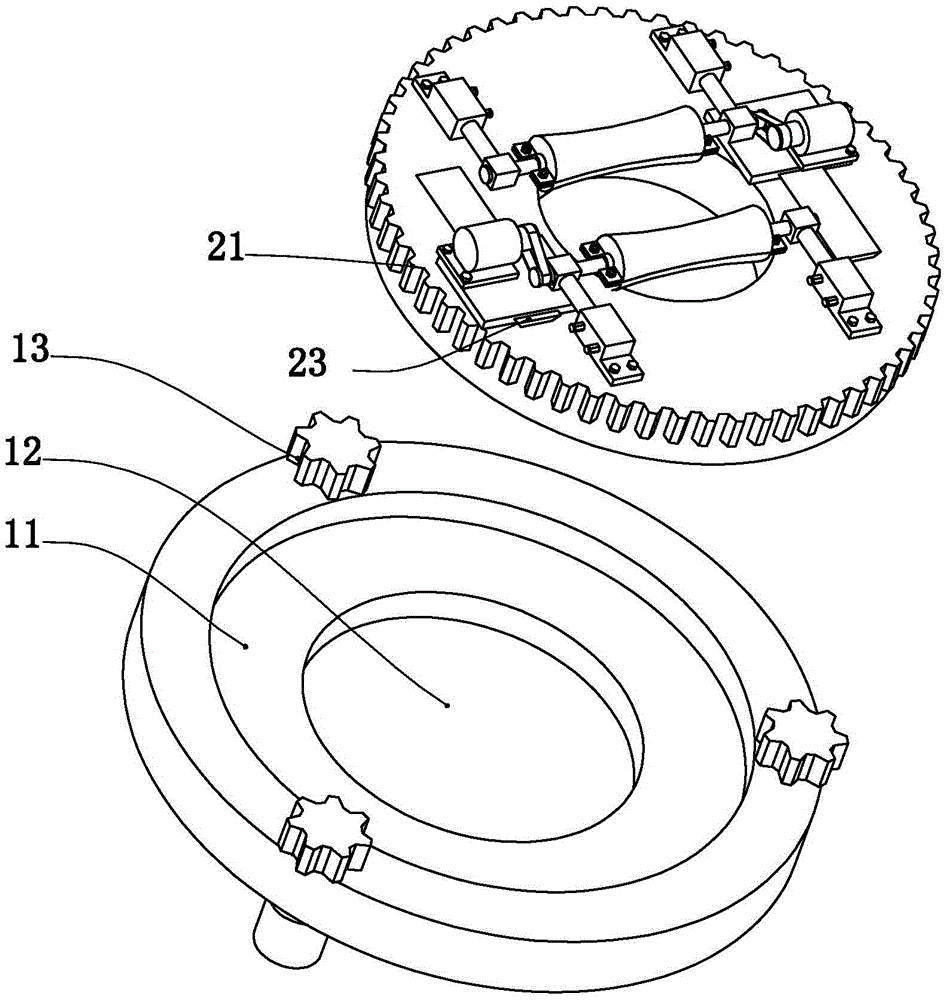

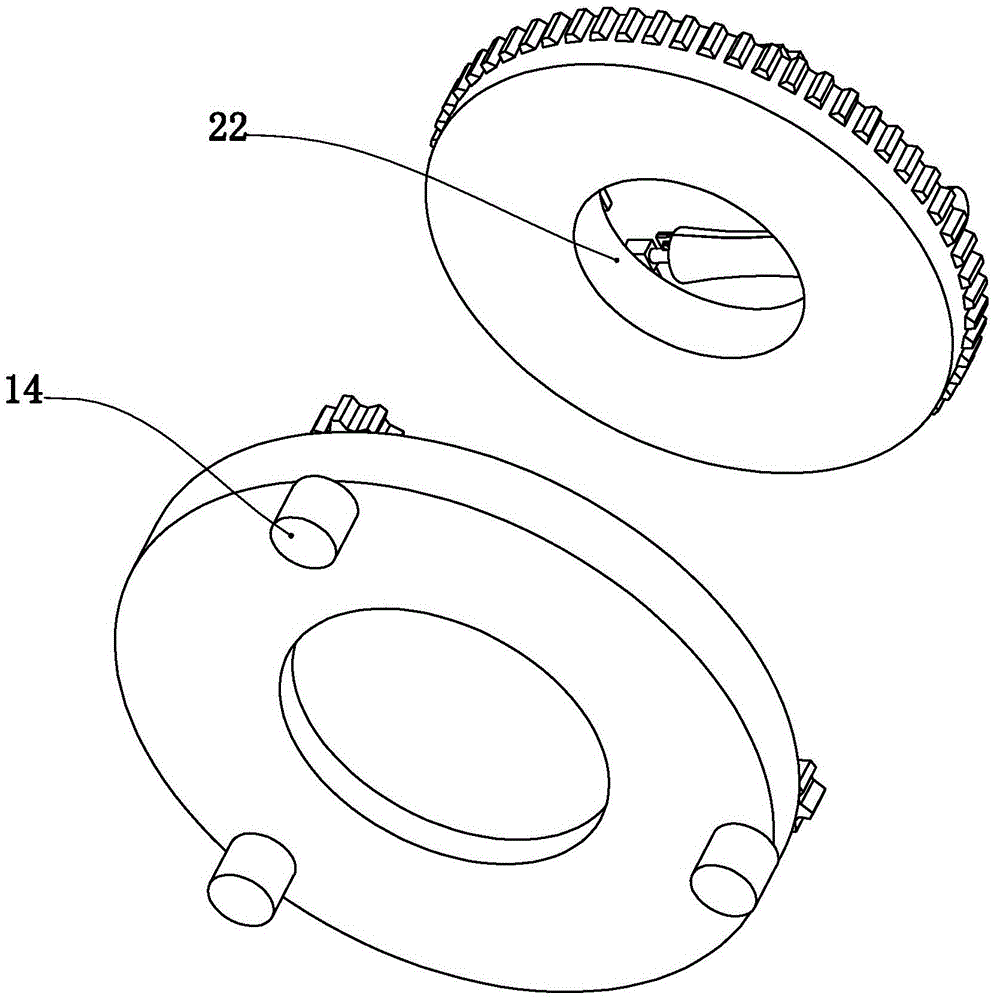

[0023] Such as Figure 1-4 The specific embodiment of the present invention shown includes a base plate 1, a rotating disk 2 and a profile clamping mechanism 3. One side of the base plate 1 is provided with a circular groove 11, and the center of the circular groove 11 is provided with a penetrating base plate. The first profile feed holes 12 on the left and right sides, the rotating disc 2 is rotatably arranged in the circular groove 11 of the base plate, and the circumference of the rotating disc 2 is evenly distributed with driving teeth 21, and the base plate 1 is rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com