Apparatus for preventing material jamming of blanking chute

A chute and material blocking technology, which is applied in the field of preventing material blocking devices in blanking chute, can solve problems such as affecting production and work efficiency, shortening the service life of the chute, normal and orderly destruction, etc., and achieves improved work efficiency, maintenance-free automation, Guarantee the effect of normal and orderly progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

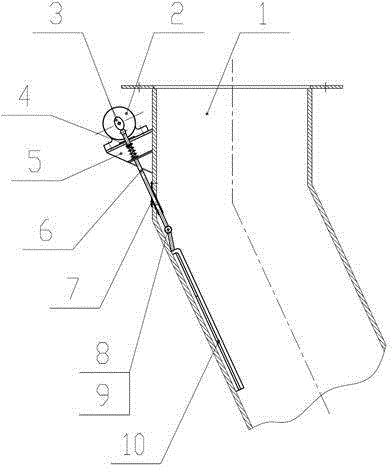

[0014] Such as figure 1 As shown, a device for preventing material blocking in the blanking chute has a mounting hole on the side wall of the blanking chute 1, and a shift fork guide sleeve 7 is installed in the mounting hole, and a shift fork guide rod 6 is installed in the shift fork guide sleeve 7. The upper end of the shift fork guide rod 6 is connected with a driving device, and the lower end of the shift fork guide rod 6 is hinged with a shift fork 10 located inside the blanking chute 1 through a pin shaft 8 and a cotter pin 9 pierced on the pin shaft. , the shift fork 10 is located on the side wall of the blanking point in the blanking chute 1, which is convenient for real-time removal of the material instantly bonded to the blanking chute; the driving device includes a motor 2 and a cam fixed on the motor sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com