A kind of thermally conductive insulating composite material and preparation method thereof

A thermally conductive insulating filler and composite material technology, applied in the field of polymer materials, can solve the problems of decreased tensile strength, ineffective improvement of thermal conductivity, and interruption of thermal conduction network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] In a typical preparation method of polyethersulfone resin and polyphenylene resin, as a first stage, the two raw materials are dissolved in an organic polar solvent, and as a second stage, an alkali of carbonic acid is added to the solution obtained in the first stage Metal salt, subjecting two raw materials to polycondensation, as the third stage, from the reaction mixture obtained in the second stage, unreacted alkali metal salt of carbonic acid, produced by-product alkali metal halide, and organic polar solvent are removed , to obtain polyethersulfone resin and polyphenylene resin.

[0046] The dissolution temperature in the first stage is usually 40 to 180°C, and the polycondensation temperature in the second stage is usually 180 to 400°C. Assuming that side reactions do not occur, the higher the polycondensation temperature is, the faster the intended polycondensation proceeds, and thus the degree of polymerization of the obtained resin becomes higher. As a result...

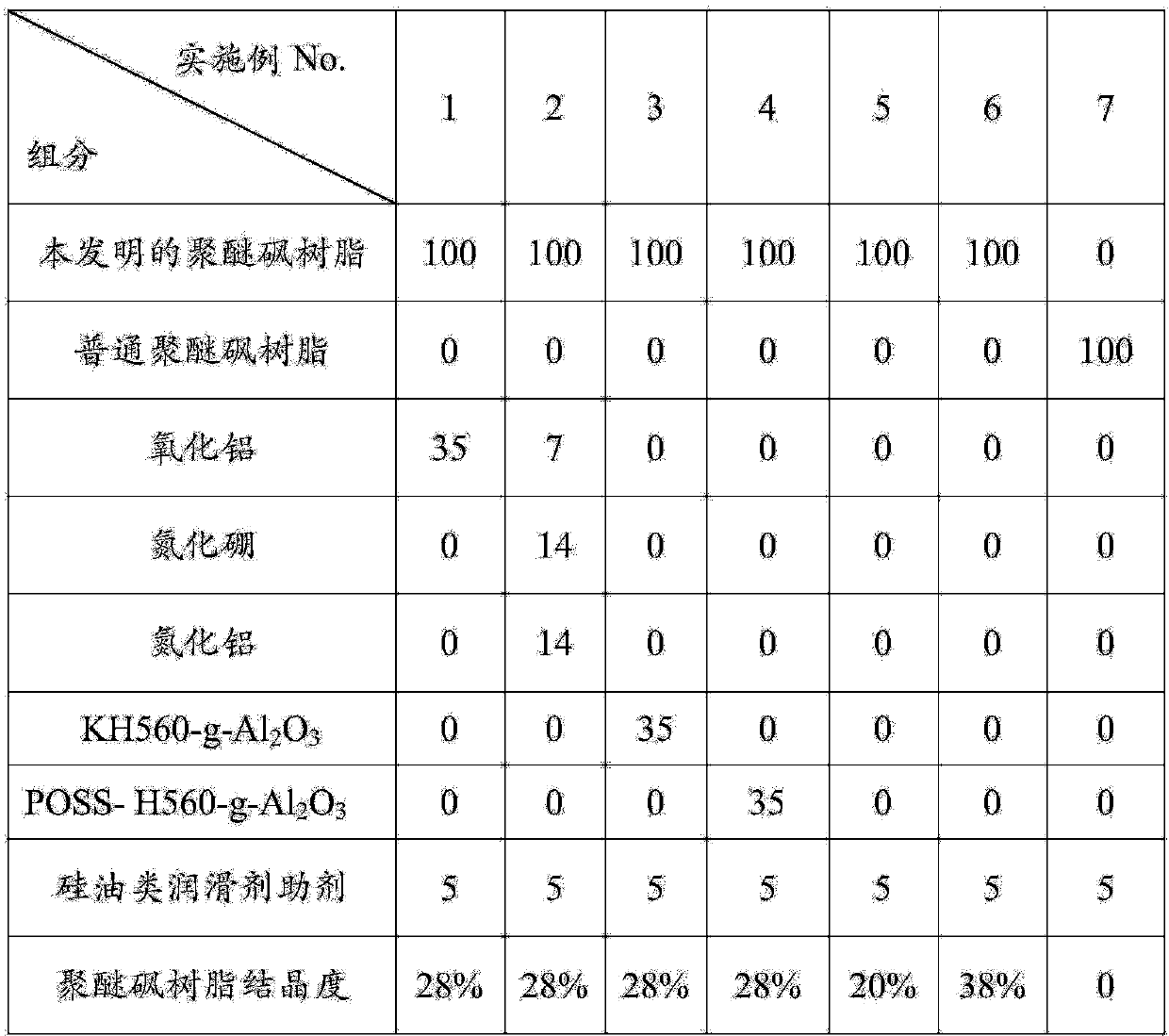

Embodiment 1~7

[0071] The preparation method of embodiment 1~7 is as follows:

[0072] (1) Dissolve polyethersulfone resin in DMF at 30-60°C, so that the concentration of polyethersulfone is 1-10g / 100mL; then drop it into deionized water at 60-90°C, and stir while adding, to obtain white Precipitation: Suction filter, wash and dry the white precipitate to obtain polyethersulfone resin powder;

[0073] (2) Putting polyethersulfone resin powder, processing aids and dry-treated fillers into a high-speed mixer for pre-mixing, melt-blending, extruding, and granulating through a twin-screw extruder to obtain the product. The temperature of the feeding port, conveying section, melting section, homogenizing section, and die of the above-mentioned twin-screw extruder are respectively 150°C, 180°C, 180°C, 180°C, and 180°C. Dry in a blast oven to obtain an insulating high thermal conductivity composite material.

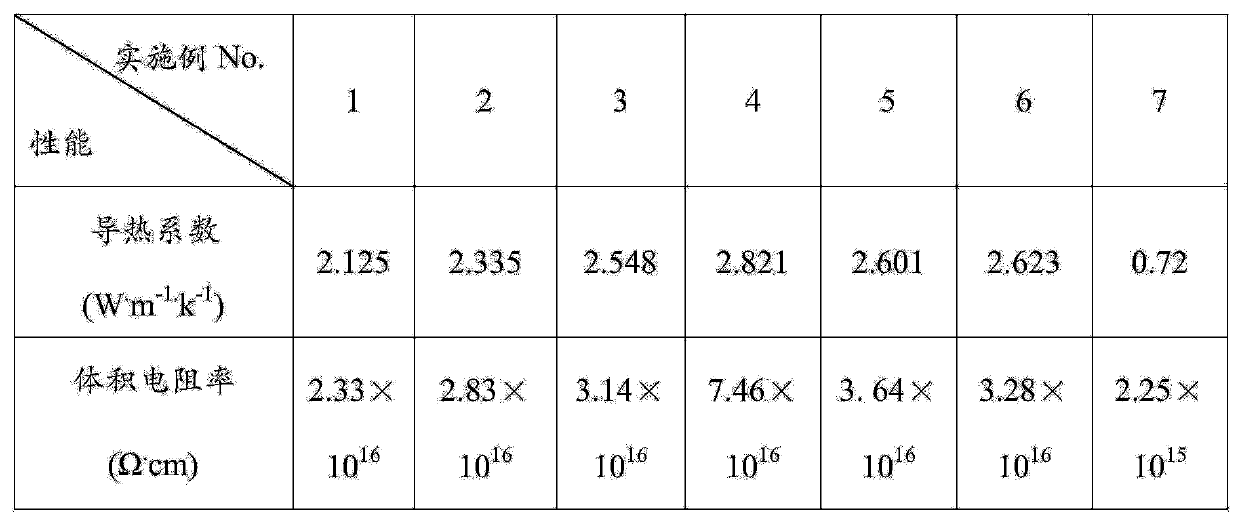

[0074] The thermal conductivity of the thermally conductive and insulating composite ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com