A low-cost, multi-functional, high-efficiency polymer-based insulating and heat-conducting composite material and its preparation method

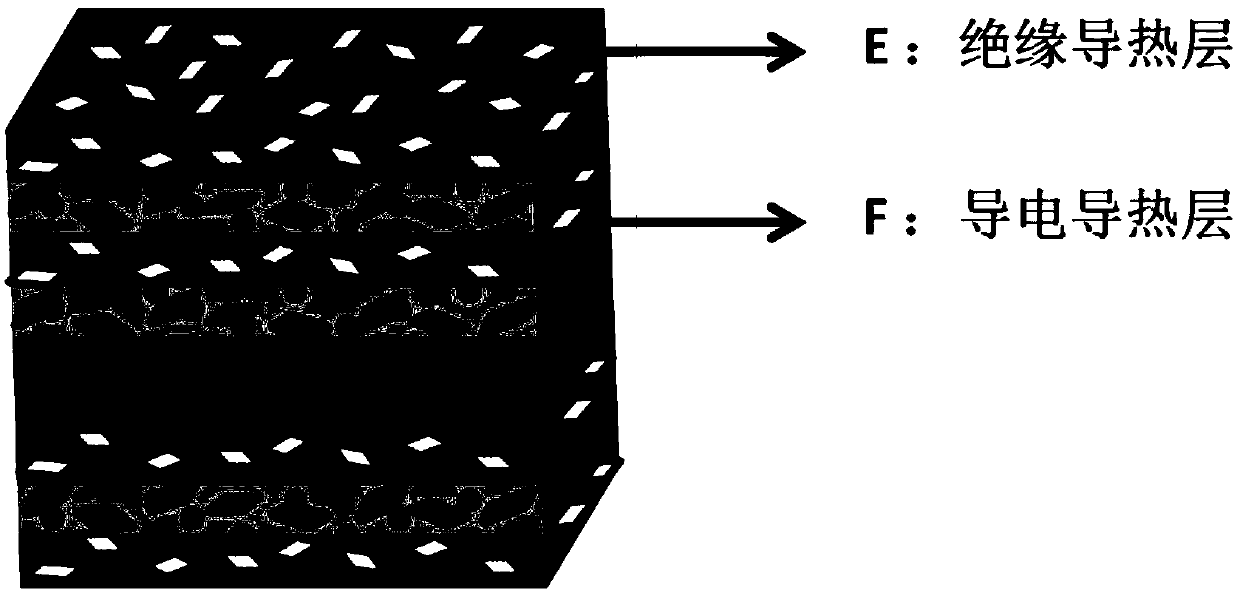

A technology of insulating and heat-conducting composite materials, applied in the field of functional composite materials, can solve the problems of uncontrollable directional distribution area of fillers, large overall performance deviation of materials, complicated processing process, etc., and achieves improved mechanical properties, good bonding condition, and operation control. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

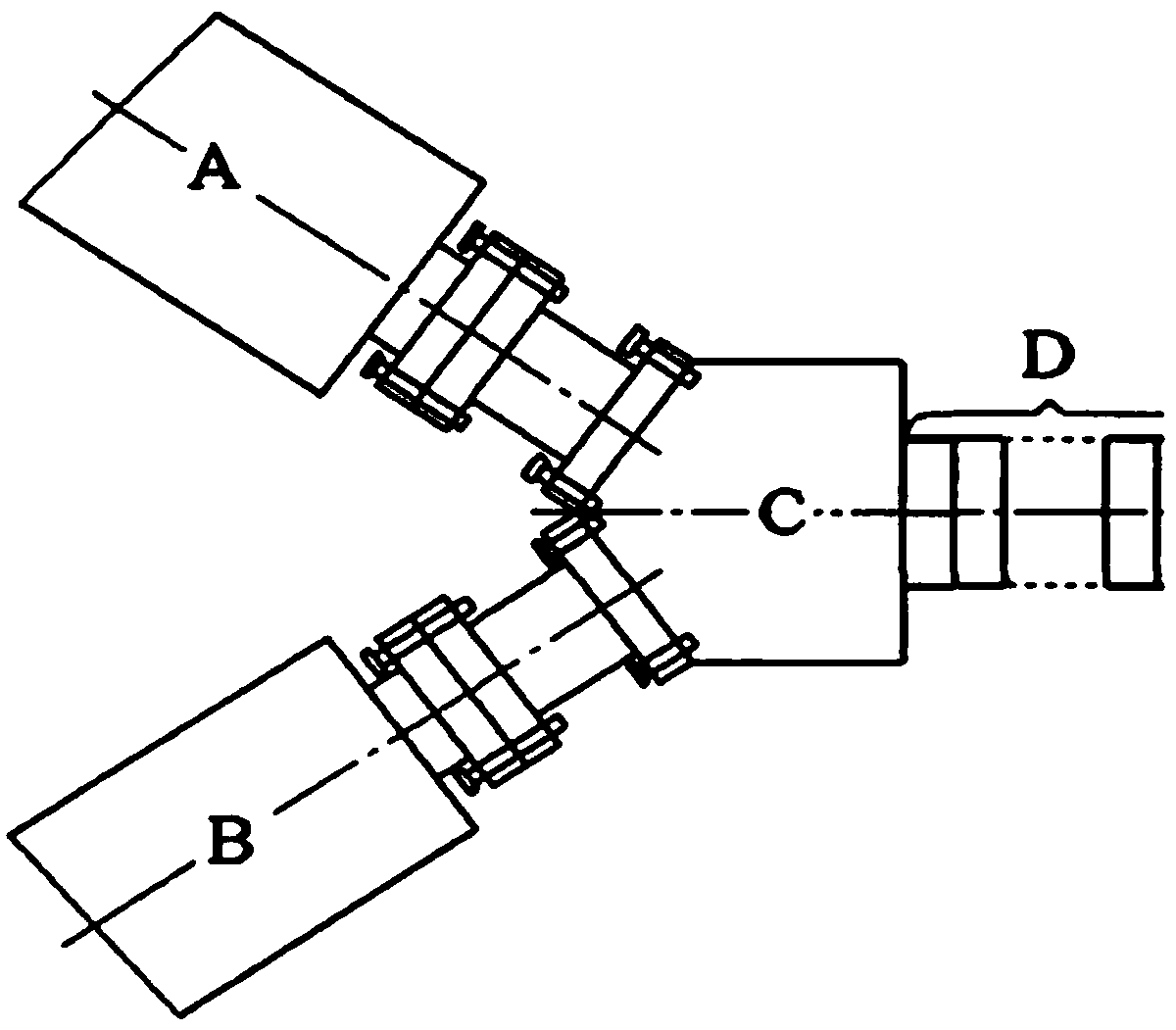

[0028] (1) Use high-density polyethylene (5000s, produced by Yanshan Petrochemical Co., Ltd.), with a melt index of 1g / 10min (190°C, 2.16kg); hexagonal boron nitride (RH-N, produced by Dandong Science and Technology Co., Ltd.), the main content 99%, boron trioxide ≤0.5%, moisture ≤0.5%, particle size 10μm; graphite (325 mesh, Qingdao Xingyuan Graphite Milk Co., Ltd.), particle size about 44μm. High-density polyethylene and boron nitride are mixed in a high-speed mixer at a weight ratio of 4:1, and high-density polyethylene and graphite are mixed in a high-speed mixer at a weight ratio of 3:2. Dry in a vacuum oven at 80°C for 12 hours.

[0029](2) Mix and granulate the dried mixture with a twin-screw extruder to form cylindrical premixed particles with a diameter of about 1mm and a length of about 3mm. Mixture, wherein the temperature of twin-screw feeding port, conveying section, melting section, homogenizing section and die is 155°C, 195°C, 195°C, 195°C, 190°C respectively. ...

Embodiment 2

[0033] (1) Use high-density polyethylene (5000s, produced by Yanshan Petrochemical Co., Ltd.), with a melt index of 1g / 10min (190°C, 2.16kg); hexagonal boron nitride (RH-N, produced by Dandong Science and Technology Co., Ltd.), the main content 99%, boron trioxide ≤0.5%, moisture ≤0.5%, particle size 10μm; graphite (325 mesh, Qingdao Xingyuan Graphite Milk Co., Ltd.), particle size about 44μm. High-density polyethylene and boron nitride are mixed in a high-speed mixer at a weight ratio of 4:1, and high-density polyethylene and graphite are mixed in a high-speed mixer at a weight ratio of 3:2. Dry in a vacuum oven at 80°C for 12 hours.

[0034] (2) Mix and granulate the dried mixture with a twin-screw extruder to form a cylindrical premix with a diameter of about 1mm and a length of about 3mm. The twin-screw feeding port, conveying section, melting section, and uniform The temperatures of the chemical section and the die are 155°C, 195°C, 195°C, 195°C, and 190°C, respectively....

Embodiment 3

[0038] (1) Use high-density polyethylene (5000s, produced by Yanshan Petrochemical Co., Ltd.), with a melt index of 1g / 10min (190°C, 2.16kg); hexagonal boron nitride (RH-N, produced by Dandong Science and Technology Co., Ltd.), the main content 99%, boron trioxide ≤0.5%, moisture ≤0.5%, particle size 10μm; graphite (325 mesh, Qingdao Xingyuan Graphite Milk Co., Ltd.), particle size about 44μm. High-density polyethylene and boron nitride are mixed in a high-speed mixer at a weight ratio of 4:1, and high-density polyethylene and graphite are mixed in a high-speed mixer at a weight ratio of 3:2. Dry in a vacuum oven at 80°C for 12 hours.

[0039] (2) Mix and granulate the dried mixture with a twin-screw extruder to form a cylindrical premix with a diameter of about 1mm and a length of about 3mm. The twin-screw feeding port, conveying section, melting section, and uniform The temperatures of the chemical section and the die are 155°C, 195°C, 195°C, 195°C, and 190°C, respectively....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com