Carbon-based electrothermal paste based on graphene clusters, its preparation method and application

A graphene cluster, graphene technology, applied in conductive materials dispersed in non-conductive inorganic materials, heating element materials, cable/conductor manufacturing, etc., can solve the problem of insufficient far-infrared radiation intensity, low electrothermal conversion efficiency, and thermal conductivity. Problems such as poor heat transfer performance, to achieve the effects of excellent thermal conductivity, reduced viscosity, and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The formula (percentage by weight) of the carbon-based electrothermal paste based on graphene clusters is as follows:

[0028] Conductive material: acetylene black (average particle size 10nm) 40%

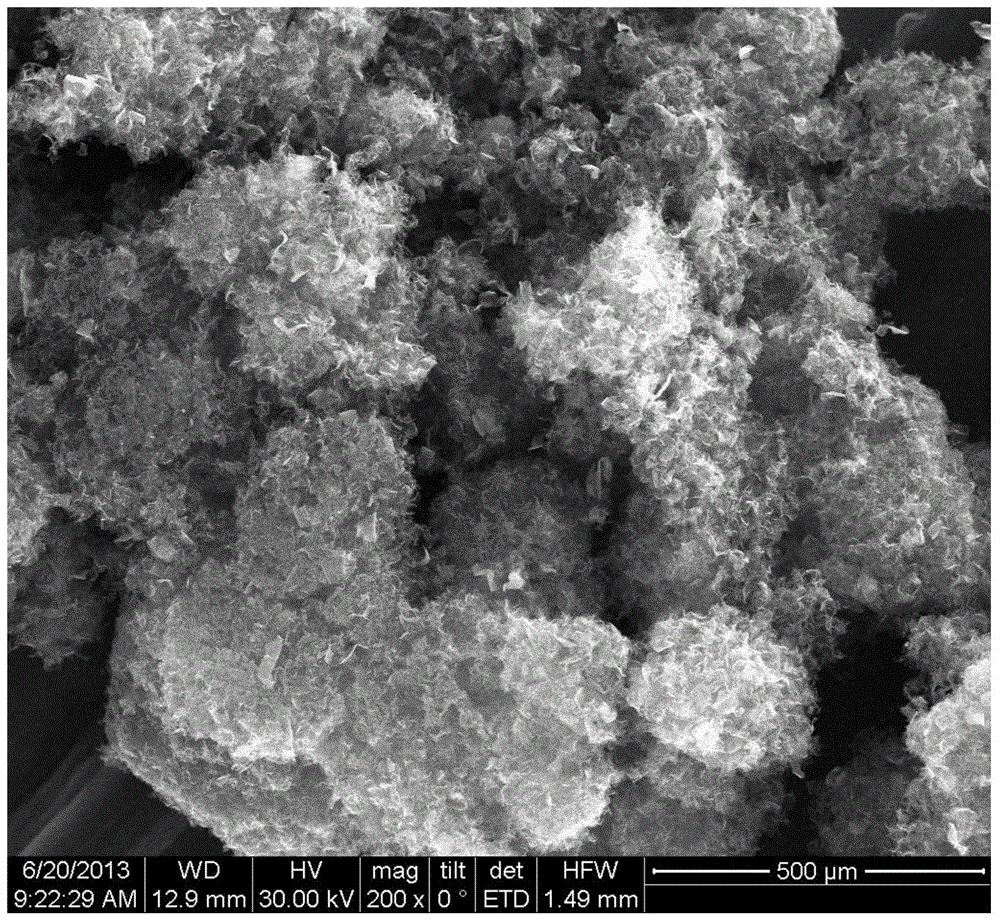

[0029] Graphene clusters (morphology such as figure 1 As shown, composed of graphene with an average size of 300μm) 2%

[0030] Water-based binder: water-based epoxy resin (Rongzhong Chemical C252) 55%

[0031] Leveling agent: Huaxia Auxiliary HX5600 (organic modified polydimethylsiloxane solution) 0.5%

[0032] Defoamer: Huaxia Auxiliary HX5041 (Mineral Oil, Foam Breaking Polysiloxane, Inorganic Hydrophobic Compound Mixture) 0.5%

[0033] Solvent: Texanol 2%.

[0034] Mix all the components according to the aforementioned formula, and mix thoroughly until uniform, to obtain the carbon-based electric heating paste of this embodiment. The slurry has excellent film-forming properties, the resistivity of the obtained film is 22Ω / cm, the thermal conductivity is 12.1W / (mK), ...

Embodiment 2

[0036] The formula (percentage by weight) of the carbon-based electrothermal paste based on graphene clusters is as follows:

[0037] Conductive carbon material: graphite (average particle size 100 microns) 25%

[0038] Graphene clusters (composed of graphene and carbon black 1:1, with an average size of 300μm) 5%

[0039] Oily vehicle: acrylic resin 69%;

[0040] Leveling agent: Huaxia Auxiliary HX5600 (organic modified polydimethylsiloxane solution) 0.5%

[0041] Defoamer: Huaxia Auxiliaries HX5041 (mineral oil, polysiloxane for breaking foam, mixture of inorganic hydrophobic compounds) 0.5%.

[0042] Mix all the components according to the formula, and mix thoroughly until uniform to obtain the carbon-based electric heating paste of this embodiment. The slurry has excellent film-forming properties, the resistivity of the obtained film is 18Ω / cm, the thermal conductivity is 10.9W / (mK), the electrothermal conversion efficiency is 98.6%, and the radiation wavelength range i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com