Alloy feeding method and device

A technology of alloy feeding and alloying, which is applied in the direction of lighting and heating equipment, furnace components, instruments, etc., can solve the problems that are prone to mistakes and errors, and cannot guarantee the stable and smooth progress of the alloy feeding production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

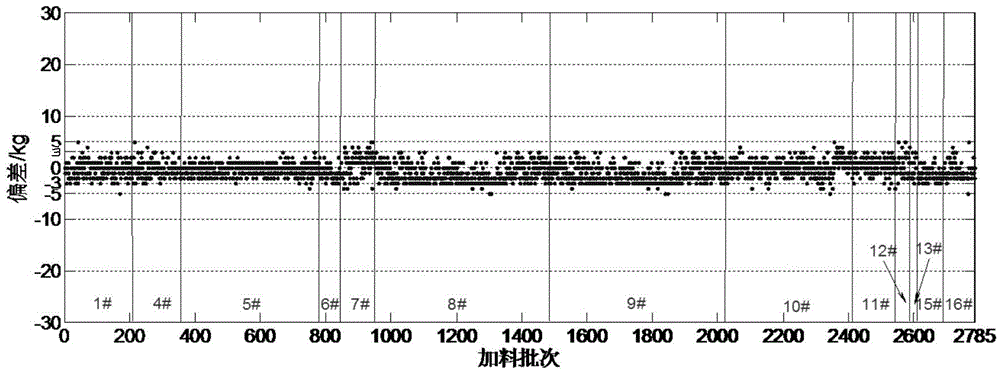

[0113] A modeling method for the weighing process of the alloy feeding system, which analyzes the relationship between the on-site process structure and historical production data and the weighing accuracy of the alloy, and the strong vibration feeding speed v F, strong vibration time t F , strong vibration time t S , transition velocity v T , transition time t T , Weak vibration feeding speed v L , weak vibration time t L , the amount of material Δm at stop vibration is used as the control parameter, and a five-stage analysis method is proposed to model the alloy feeding process mathematically, and expert rules are introduced to optimize the model. Specific steps are as follows:

[0114] (1) collect data samples in the on-site computer server;

[0115] Analyze the historical production data of the alloy feeding process, add the tag position of the required data in the on-site computer server, take 0.5s as the sampling time, and analyze the feeding start time, strong vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com