Sewing machine head used for processing shirt sleeve caps

A technology of sewing machine head and sleeve head, which is applied in the direction of sewing machine components, sewing equipment, cloth feeding mechanism, etc., can solve the problems of uneven processing quality and low work efficiency, and achieve the effects of reducing processing difficulty, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

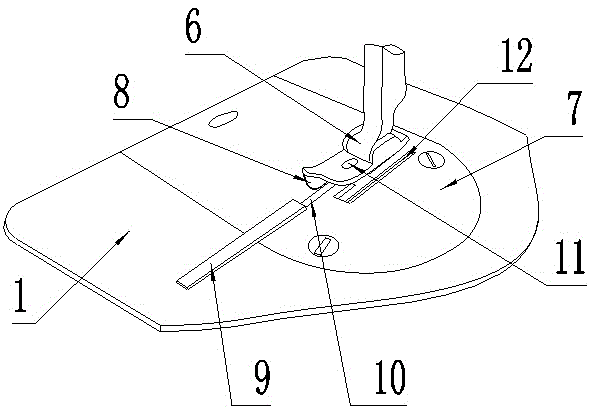

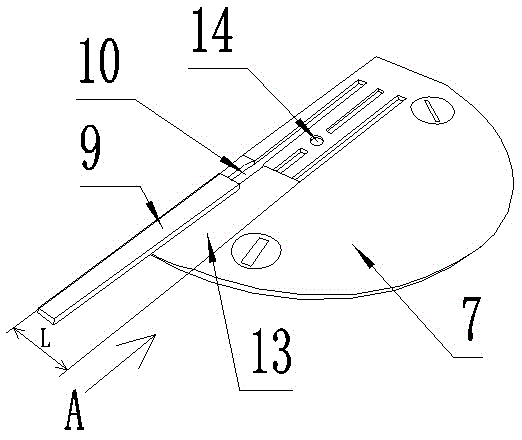

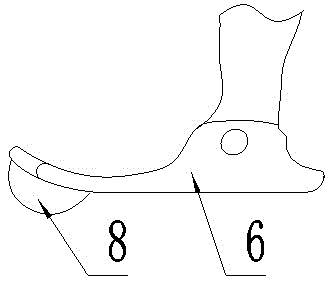

[0018] Such as Figure 1-6 The shown sewing machine head for processing shirt sleeves includes a base plate 1 and a machine head body 2. There is a presser foot 6 below the machine head body 2, and a needle plate 7 is provided on the base plate 1 corresponding to the presser foot 6. The needle plate 7 is provided with a rectangular hole 12 cooperating with the cloth feed dog, and the left limiting plate 8 on the inner edge of the front side of the sleeve is fixed under the raised part of the presser foot 6, and the needle plate 7 is fixed with a The left limiting plate 9 of the inner edge of the reverse side of the cuff, the left limiting plate 8 of the inner edge of the front of the cuff and the right edge of the left limiting plate 9 of the inner edge of the reverse of the sleeve are aligned, and the alignment surface is set On the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap