Connected anchor rod and mounting method thereof

A technology of anchor rod and rod body, which is applied in the direction of construction, sheet pile wall, foundation structure engineering, etc., can solve the problems of single force, easy bending and damage, etc., and achieve the effect of convenient installation and operation, avoiding bending damage and shortening the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

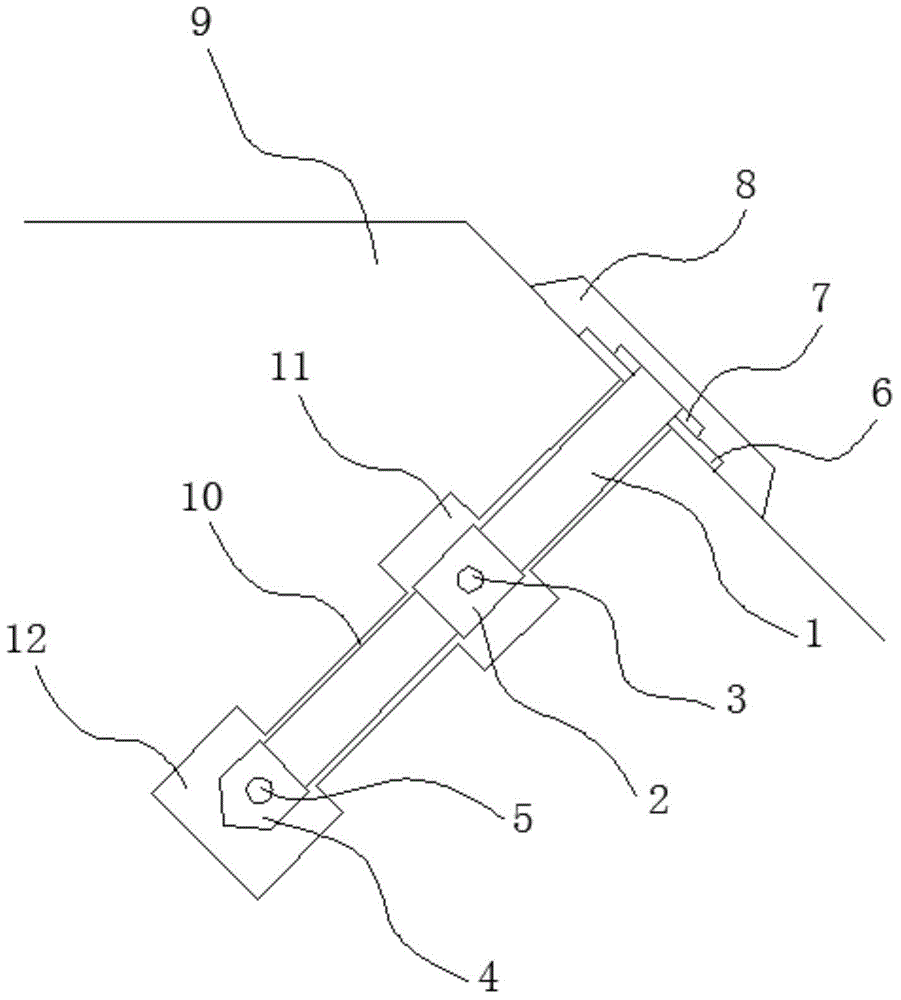

[0028] A takeover type anchor rod, which includes: a rod body 1, a connecting sleeve 2, an anchor head 4, a backing plate 6, and a cover 8, wherein: the rod body 1 is in the shape of a hollow tube with openings at the upper and lower ends, and at least two rod bodies 1 The connection is carried out through the connection sleeve 2 , preferably, the upper and lower ends of the connection sleeve 2 are respectively threaded with the two upper and lower adjacent rod bodies 1 . When it is necessary to install a shorter anchor rod on the slope 9, it can be formed by connecting only two rod bodies 1 through the connecting sleeve 2; They are connected in sequence, and the anchor rod can be split into a plurality of relatively short rod bodies 1 during transportation by forming the anchor rod in the form of connecting pipes, so as to effectively avoid bending damage to the anchor rod during transportation. The diameter of the connecting sleeve 2 is greater than that of the rod body 1, a...

Embodiment 2

[0032] Such as figure 1 Shown, a kind of installation method of above-mentioned takeover type anchor rod, comprises the following steps:

[0033] First, drill the guide hole 10 on the slope 9, the diameter of the guide hole 10 can be greater than the diameter of the anchor head 5 and the connecting sleeve 2, when the diameter of the anchor head 5 and the connecting sleeve 2 are the same, it can ensure that the guide hole 10 The gap between the anchor rod and the whole is relatively uniform.

[0034] Second, the position corresponding to the guide hole 10 and the connecting sleeve 2 on the takeover anchor rod is reamed to form a first chamber 11; and the lower end of the guide hole 10 is reamed to form a second chamber 12.

[0035] Third, assemble several rod bodies 1, connecting sleeves 2 and anchor heads 4, and then insert the assembled whole into the guide hole 10. Since the lower end of the anchor head 4 is pointed, the rod body 1 can be easily and smoothly introduced int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com