Single-tank heat storage device with phase change heat storage function and use method thereof

A phase change heat storage and heat storage device technology, which is applied in the direction of heat storage equipment, indirect heat exchangers, heat exchanger types, etc., can solve the problems of not considering the utilization of latent heat, huge heat storage devices, and high system investment and maintenance costs , to achieve the effects of compact structure, stable heat release process and expanded working range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

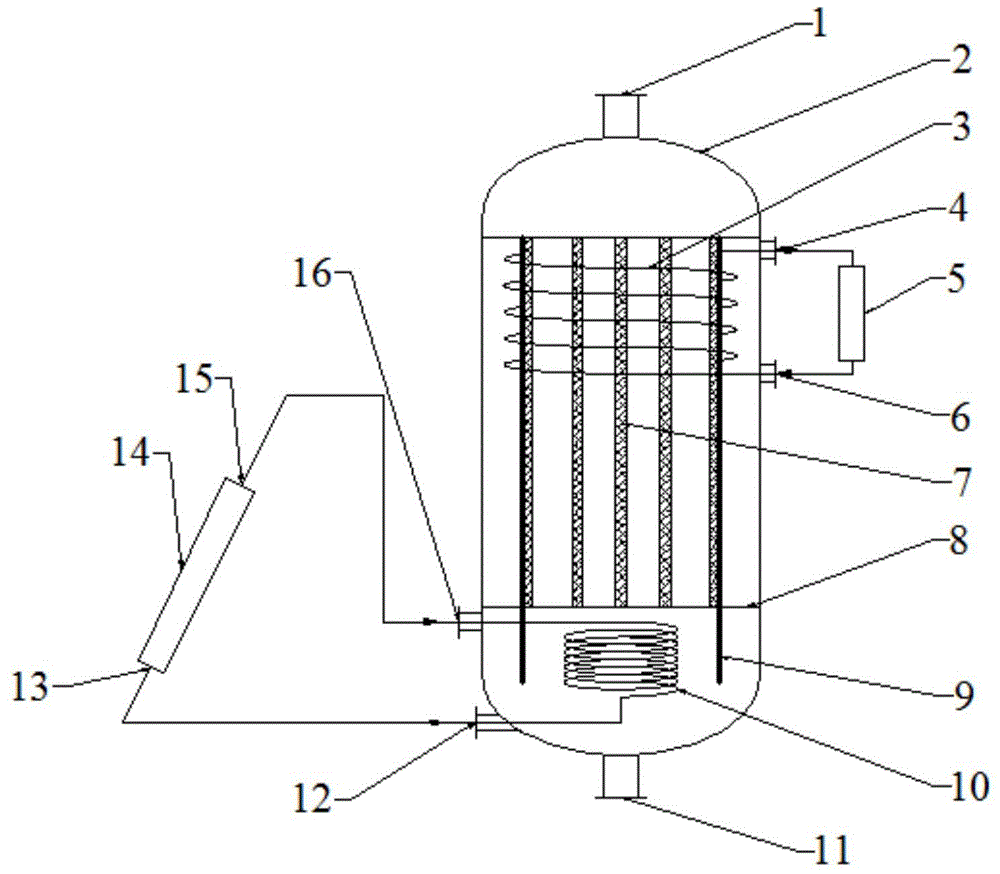

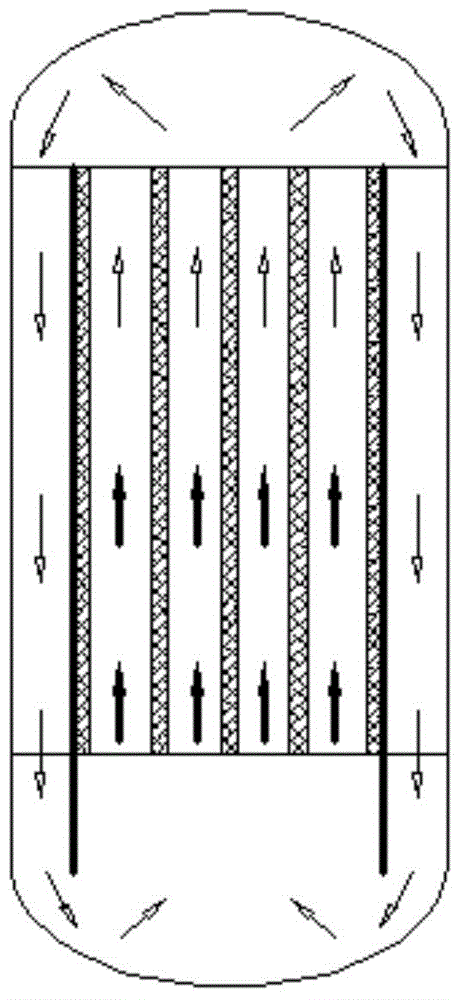

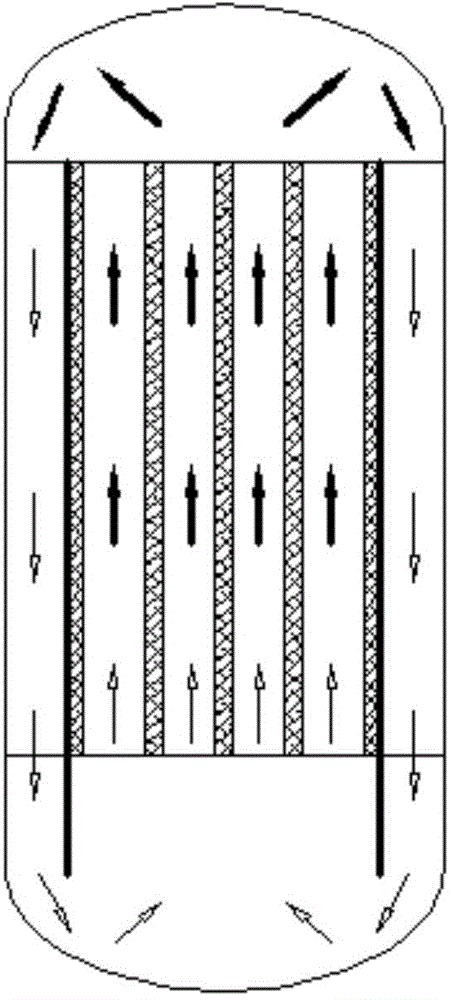

[0039] Example 1, such as Figure 1-4 As shown, a single-tank heat storage device with phase change heat storage described in the first embodiment of the present invention includes:

[0040] The single-tank regenerator 2 has a heat storage medium inlet 1 on the top outside and a heat storage medium outlet 11 on the bottom outside;

[0041] Heat insulation plate 9, which is arranged inside the single-tank heat accumulator 2 and arranged coaxially with the single-tank heat accumulator 2;

[0042] The phase change heat storage device 7 is arranged inside the heat insulation plate 9 and fixed inside the single tank heat accumulator 2 through the tube sheet 8, and the phase change heat storage device 7 is filled with a phase change heat storage medium;

[0043] The exothermic coil heat exchanger 3 is arranged on the upper part of the annular channel formed by the heat insulation plate 9 and the single-tank heat accumulator 2. The medium inlet 6 is connected to the exothermic medi...

Embodiment 2

[0057] Example 2, such as Figure 5 As shown, the single-tank heat storage device with phase change heat storage described in the second embodiment of the present invention is similar to Embodiment 1, the difference is that:

[0058] The heat transfer medium and the heat storage medium are the same medium, and the heat storage coil heat exchanger 10 at the inner bottom of the single-tank heat accumulator 2 is omitted. Tank accumulator 2. The heat transfer medium outlet 12 and the heat transfer medium inlet 16 are omitted, and the heat transfer medium from the solar heat collector 14 enters the single-tank heat accumulator 2 from the heat storage medium inlet 1, and pushes the low-temperature medium in the single-tank heat accumulator 2 to It moves downward, flows out from the heat storage medium outlet 11 at the bottom, and then enters the solar heat collector 14 for heating.

Embodiment 3

[0059] Example 3, such as Figure 6 As shown, the single-tank heat storage device with phase change heat storage described in the third embodiment of the present invention is similar to Embodiment 2, the difference is that:

[0060] The size of the phase-change heat storage device 7 is reduced, and a coil electric heater 17 is installed at the bottom of the single-tank heat accumulator 2, and a power supply device 19 is added outside the single-tank heat accumulator 2, and the coil electric heating The device 17 is connected to the power supply equipment 19 through the inlet 18 of the electric heating equipment. When the solar thermal energy stored by the solar heat collector 14 is insufficient during the day, the coil electric heater 17 can be used for electric heating at night to realize the heat storage process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com