Device and method for measuring early-age relative humidity of cement-based material

A cement-based material and relative humidity technology, applied in the direction of material inspection products, etc., can solve the problems of low measurement error, less early relative humidity, and little significance of data research, so as to reduce test cost, accurate and reliable test data, and avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

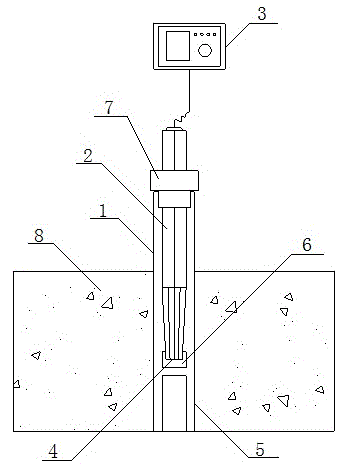

[0033] Such as figure 1As shown, in the actual application process, a relative humidity measuring device of a kind of cement-based material designed by the present invention includes a casing 1, a humidity sensor 2 and a data acquisition instrument 3; wherein, the probe 4 of the humidity sensor 2 is formed by the casing The top opening of 1 is inserted into casing 1, the probe 4 of humidity sensor 2 is located at the bottom of casing 1, and does not protrude from the opening at the bottom of casing 1; the side wall of casing 1 is in the same position as probe 4 of humidity sensor 2 At least one through hole 6 is set at the corresponding position, and the design of the through hole 6 is to enable the humidity sensor 2 to have enough contact space with the cement-based material to ensure the accuracy of the humidity sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com