Intelligent weaving workshop travelling cleaner

A cleaning machine, intelligent technology, applied in the two-dimensional position/channel control and other directions, can solve the problems that the traveling cleaning machine can only continuously absorb air, waste energy, affect efficiency, etc., so as to reduce energy consumption and improve loom efficiency. , Improve the effect of weaving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

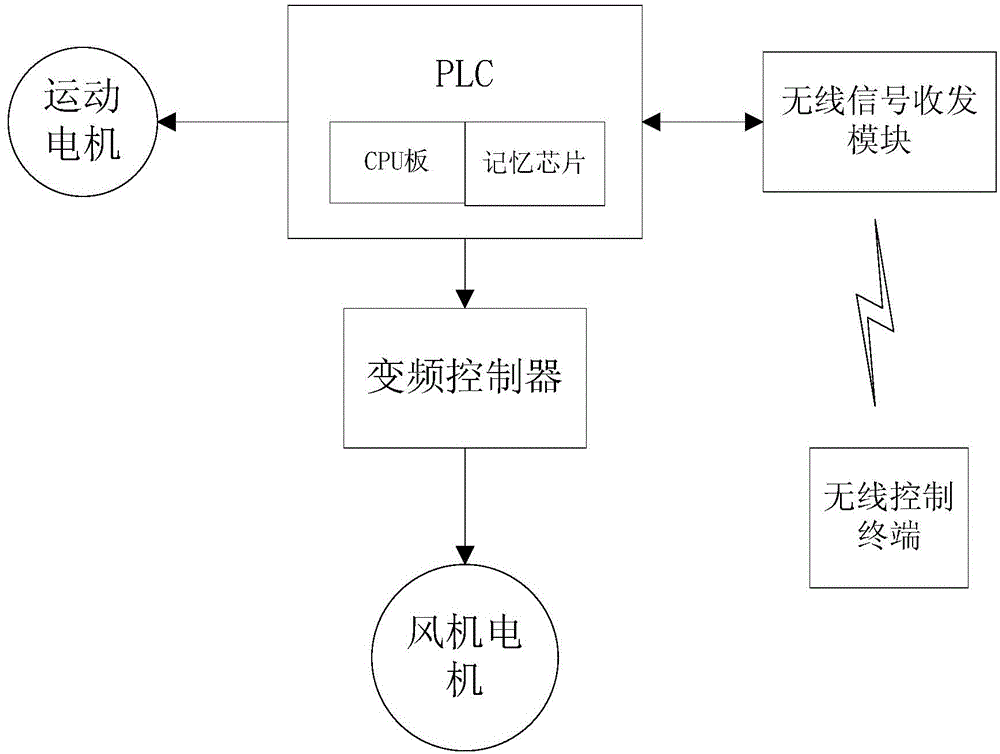

[0024] Such as figure 1 As shown, an intelligent itinerant cleaning machine for a weaving workshop of the present invention has a motion mechanism. The controller is connected to the fan motor, and the fan motor is connected to the AC power supply through the AC contactor. The PLC and the frequency conversion controller are installed in the frame of the itinerant cleaning machine. Fly flower nets are arranged on both sides of the suction pipe and / or blow pipe to collect the fly flowers outside the fabric fell. After the side cutting of the flying flower net, the blowing and suction ducts are adjusted on both sides to adjust the blowing direction separately, so that the flying flower is directly blown to the flying flower net, which improves the original direction of the flying flower, changing the original one-way blowing to blowing to both sides separately, Use the flying flower net to collect flying flowers at the outermost side of the weaving fell. It greatly reduces the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com