A spark plug and a high voltage ignition wire

A technology of spark plugs and high-voltage caps, applied in the field of spark plugs and their matching high-voltage ignition wires, can solve the problems of weak initial spark, difficult to ignite, short life, etc., and achieve the effect of strong initial spark, accurate ignition time, and suppression of interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

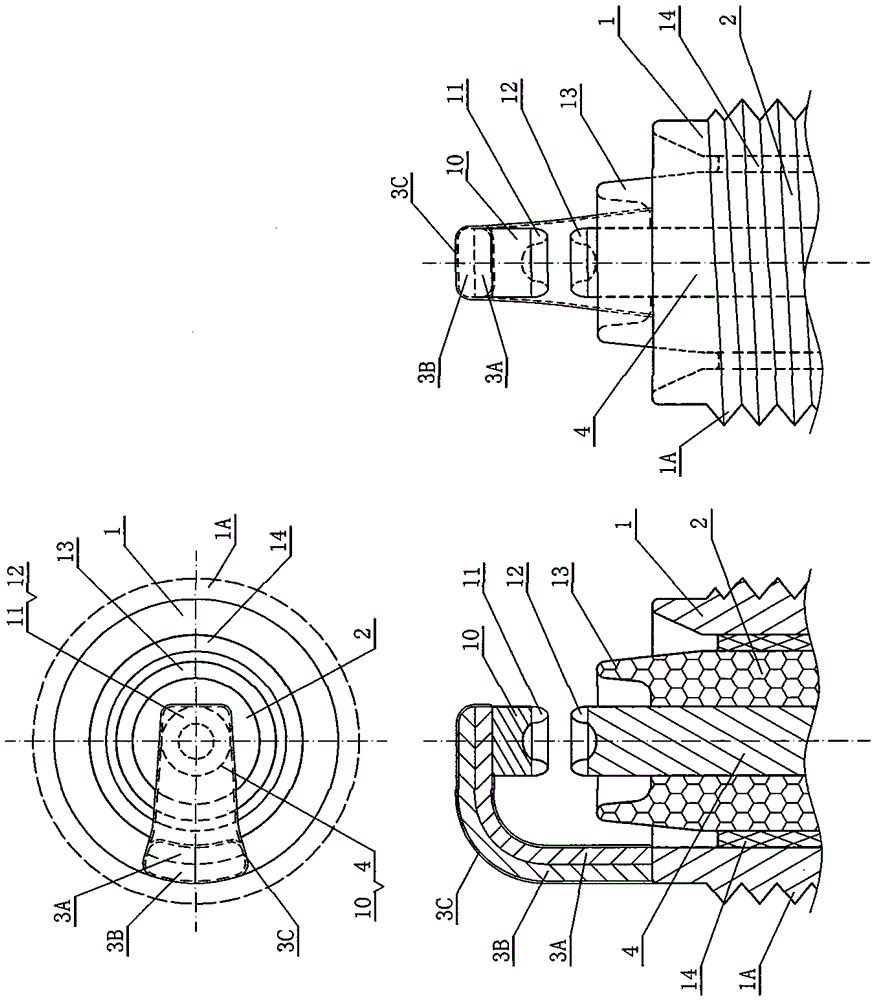

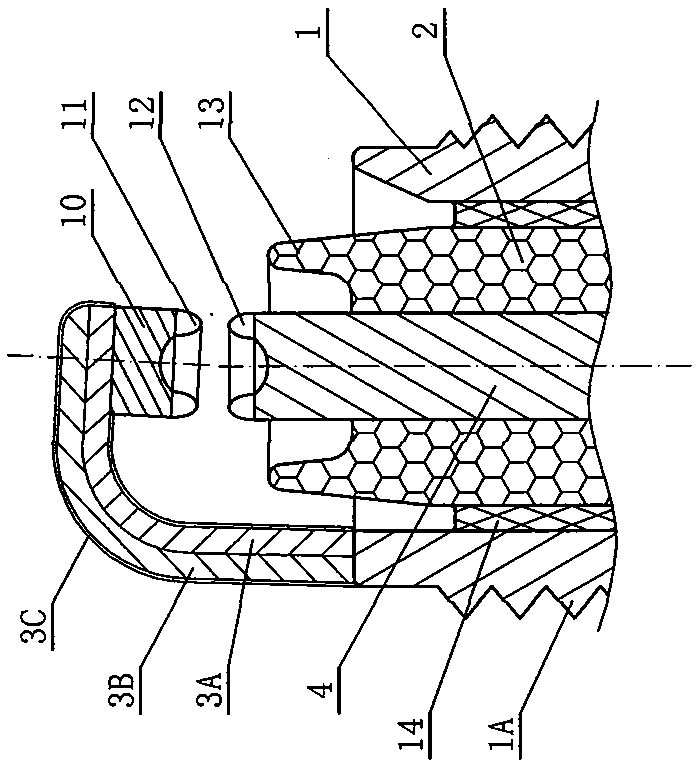

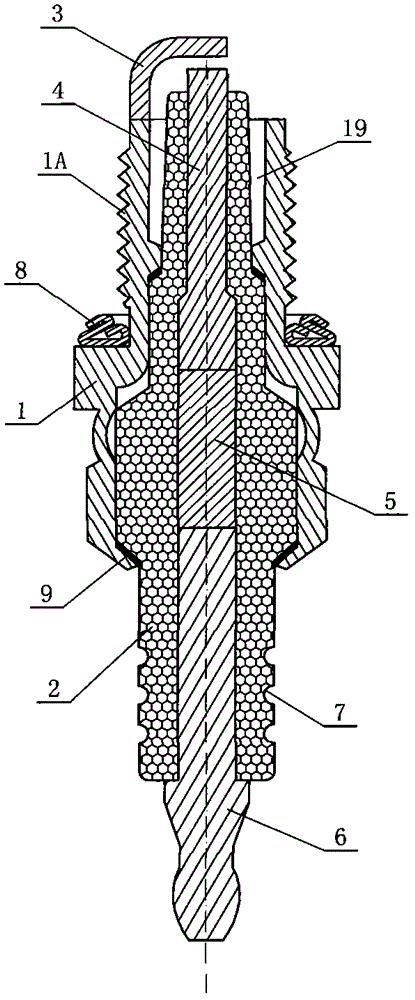

[0063] exist figure 2 Among them, a spark plug is mainly composed of main parts 1, ceramic insulating cylinder 2, side electrodes, center electrode 4, current limiting resistor 5, terminal electrode 6, sealing gasket 8, liner plate 9, heat insulating material 14, shielding cylinder 15 And rubber ring 17, wherein the side electrode is composed of side electrode inner layer 3A, side electrode outer layer 3B, small cylinder 10 and side convex electrode ring 11. The coefficient of thermal expansion and contraction of the side electrode inner layer 3A is greater than that of the side electrode outer layer 3B. The width of the lower end of the side electrode is 1.5 times the width of the upper end.

[0064] The diameter of the small cylinder 10 is equal to the diameter of the upper end of the center electrode 4 , and the bottom surface of the small cylinder 10 is laser-welded with a protruding electrode ring 11 , and the bottom surface of the small cylinder 10 in the protruding el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com