Mobile phone camera frame and manufacturing method thereof

A mobile phone camera and manufacturing method technology, applied in image communication, telephone structure, television, etc., can solve the problems of raw material waste, long processing time, high production cost, etc., achieve raw material saving, controllable processing, increase The effect of maximum flexibility and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific embodiments.

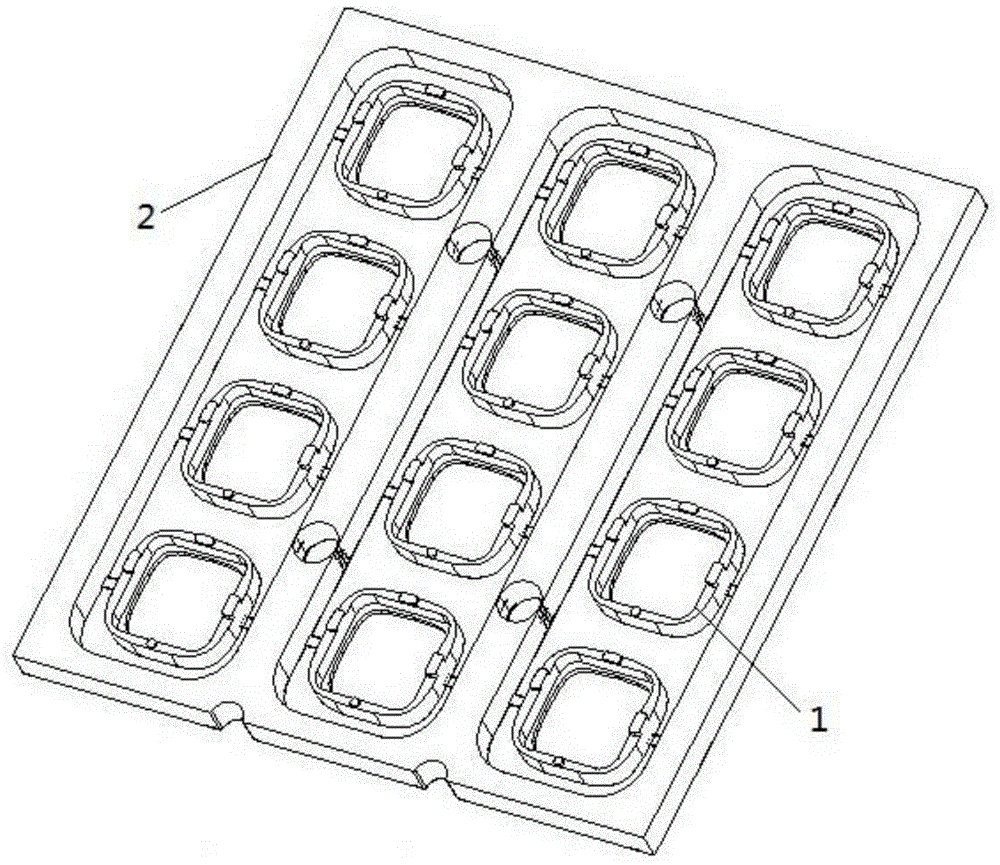

[0027] like Figure 1 to Figure 5 As shown, a mobile phone camera frame includes a rectangular frame body 1, a rectangular camera window 103 is arranged in the frame body 1, the frame body 1 has two end faces, and the outside of the upper end face of the frame body 1 is provided with a chamfer 102, A lower surface of the frame body 1 is provided with several buckles 101 .

[0028] A method for manufacturing a mobile phone camera frame, comprising the following steps:

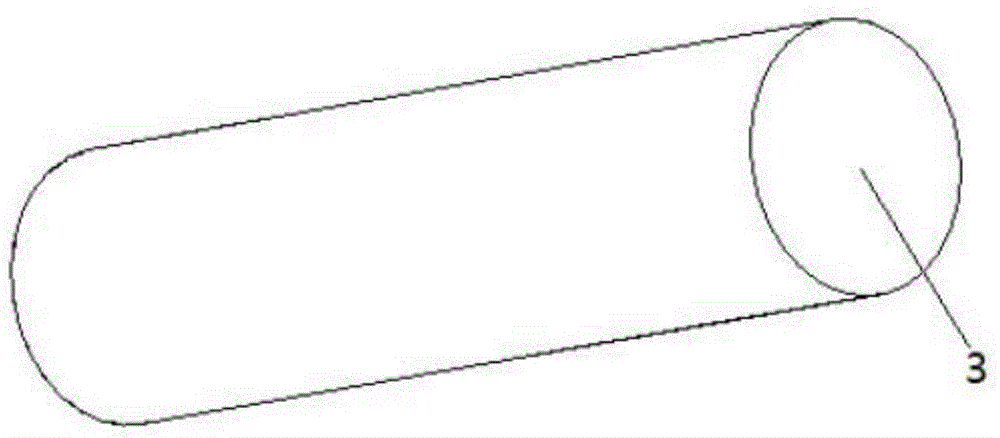

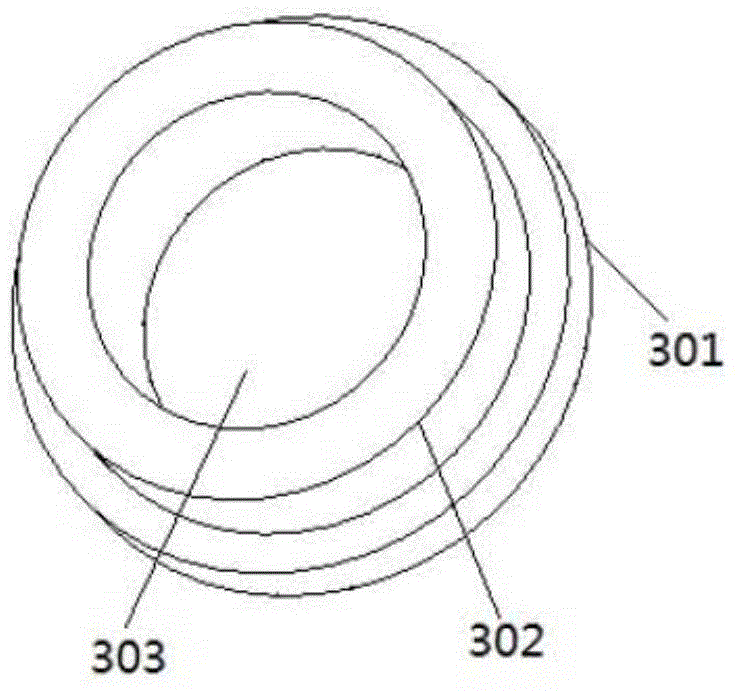

[0029] 1) Rough machining blanks: use rods 3 with a diameter of 16mm, such as figure 2 As shown, the length can be set arbitrarily according to the production requirements. The material of the bar 3 is 304 stainless steel, and the bar 3 is cut into several ring parts by a vertical automatic turning machine tool. The ring parts include an integrally formed first ring body 302 and the second ring body 301, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com