An accessory mount

A technology for mounting seats and accessories, which is applied to agricultural machinery and implements, applications, agricultural machinery, etc. It can solve problems such as large cantilever beam force, large damage to the rotary tiller, deformation of the cantilever beam or chassis frame, etc., and achieves easy replacement , Reduce maintenance costs and improve maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

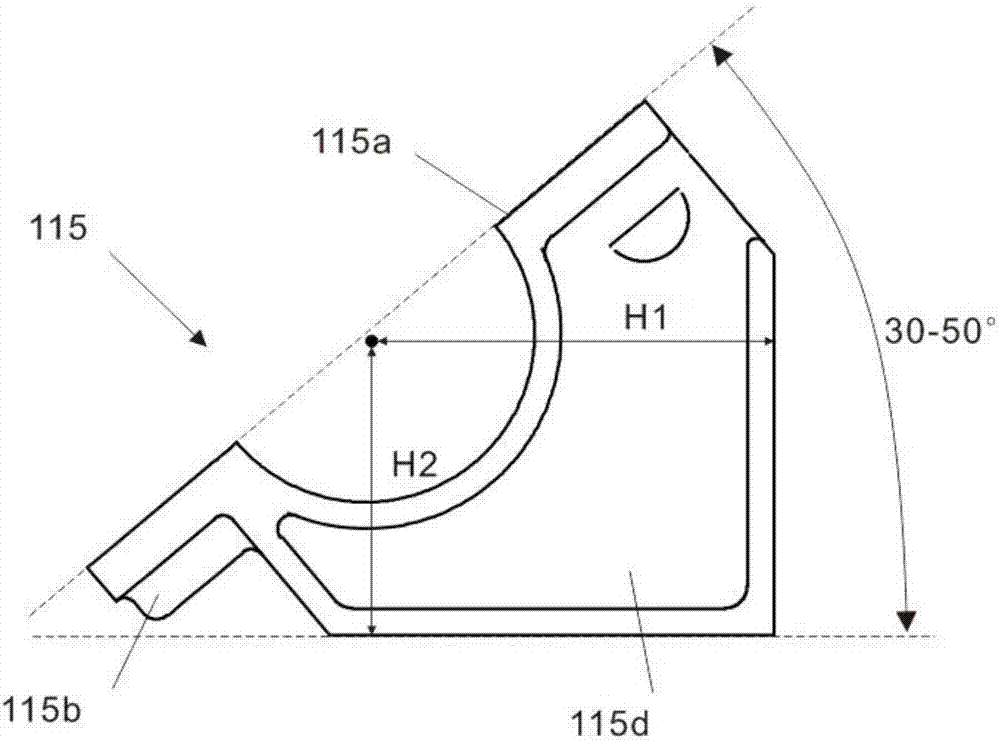

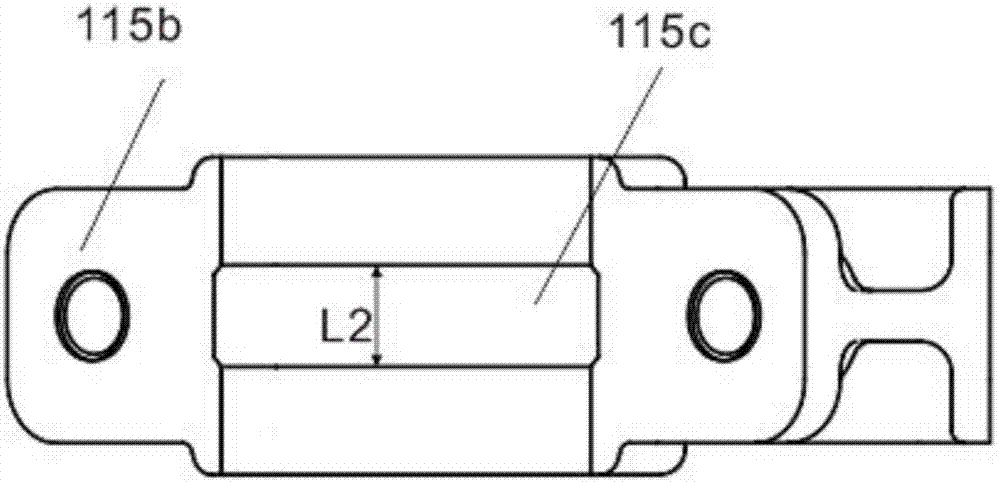

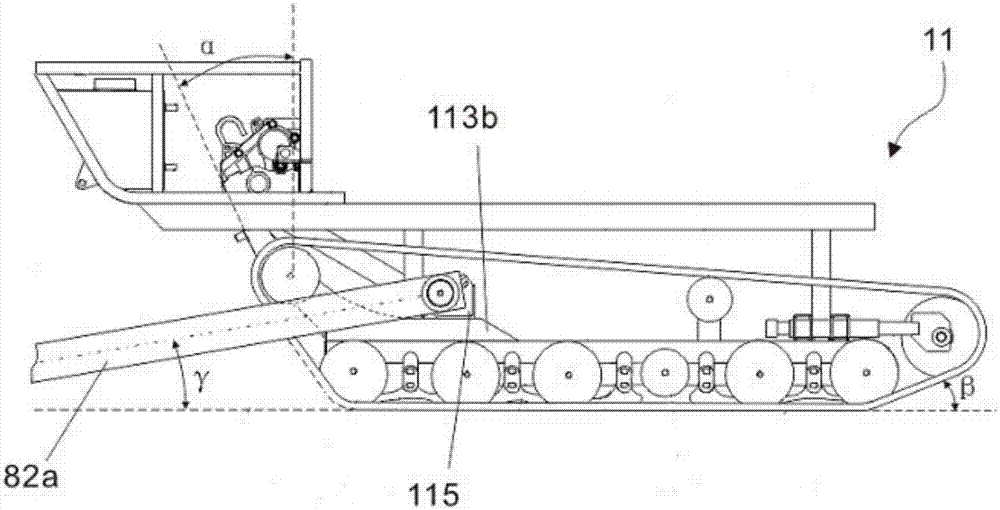

[0021] An accessory mounting seat, which is made of cast iron and has an integral structure, the accessory mounting seat 115 has a mounting surface 115a, the mounting surface 115a is inclined relative to the horizontal plane, and the inclination angle is 40°, the front end of the mounting surface 115a and the rear The end is a lug-shaped mounting ear 115b, and the center of the mounting ear 115b is provided with a bolt hole, and is fastened to the bolt hole of the left and right heightening beams 113b of the chassis frame 11 through bolts. On the top, the bottom of the mounting surface 115a is a base 115d along its longitudinal axis and perpendicular to the mounting surface 115a. The mounting surface 115a also has a semi-cylindrical opening whose center line is consistent with its transverse axis direction. The center line of the semi-cylindrical opening is The distance H1=12cm to the rear end face of the base, the distance H2=9cm from the center line of the semicylindrical ope...

Embodiment 2

[0024] The second embodiment of the present invention is improved on the basis of the first embodiment, and its main difference from the embodiment is that the installation surface 115a is inclined relative to the horizontal plane, the inclination angle is 35°, and the width L2 of the groove 115c = 4cm, the width of the semi-cylindrical opening = 14cm, it also includes a matching upper cover, the lower surface of the upper cover also has a semi-cylindrical opening, and can cooperate with the semi-cylindrical opening on the mounting surface 115a , forming a closed cylinder, the surface of the semi-cylindrical opening of the upper cover is provided with a concentric semicircular groove, the width of the groove is the same as the width L2 of the groove 115c of the accessory mount 115, the base The bottom surface of 115d is parallel to the ground, and the distance between it and the ground is 35cm. In order to make the angle γ≤8° between the accessory cantilever beam 82a and the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com