A painless suction medical needle and its production process

A medical and painless technology, applied in the field of medical equipment, can solve the problems of secondary injury, deepening of the patient's pain, stabbing the patient, etc., to achieve the effect of reducing pain, good injection effect, and beautiful surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

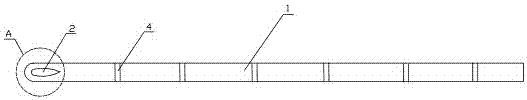

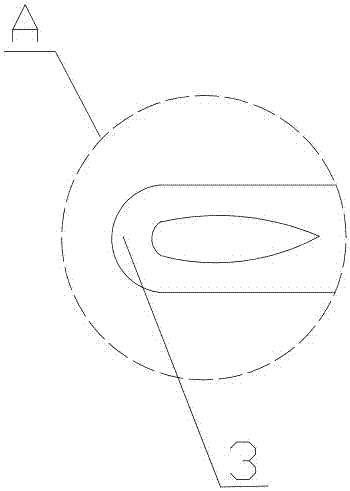

[0016] Combine now figure 1 , figure 2 To further illustrate the present invention, a painless suction medical needle includes a needle body 1, and the needle body 1 is made of 304 stainless steel. The needle body 1 is a hollow cylinder, and a pinhole 2 is opened on the side of the needle body 1, and the pinhole 2 is formed by laser cutting. The top of the needle body 1 is provided with a needle head 3 in contact with the human body, the needle head 3 is a smooth curved surface, and the needle head 3 and the needle body 1 are connected by welding. The needle body 1 is evenly provided with several scale marks 4 for marking the insertion depth of the needle body 1 into the human body. The scale marks 4 are etched on the surface of the needle body 1 by chemical corrosion. The present invention welds the front end of the suction medical needle with a smooth arc-shaped needle 3 through a welding process, so that the needle 3 will not stab the patient in the body and cause unavo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com