Patents

Literature

31results about How to "Not easy to separate and fall off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

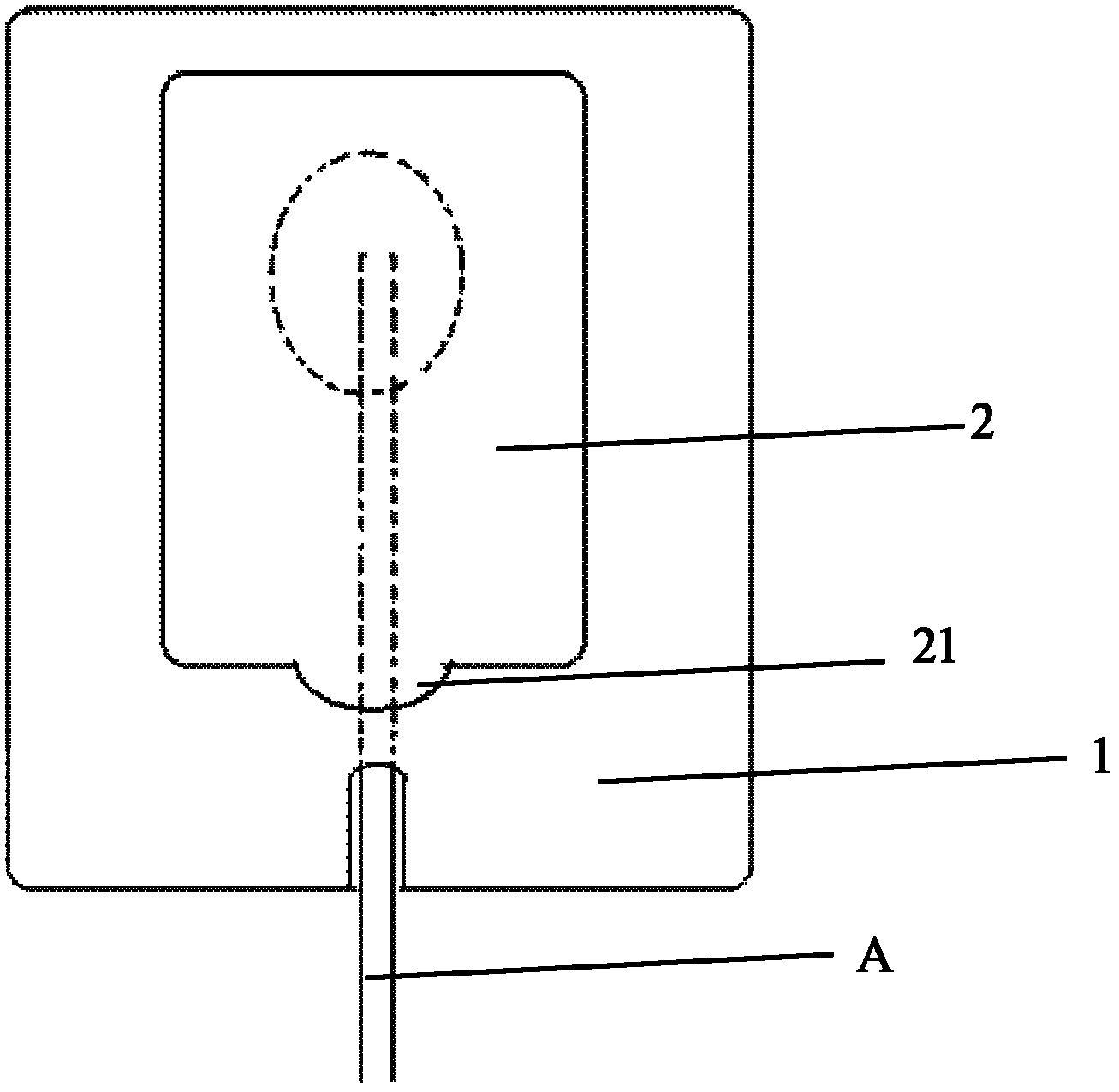

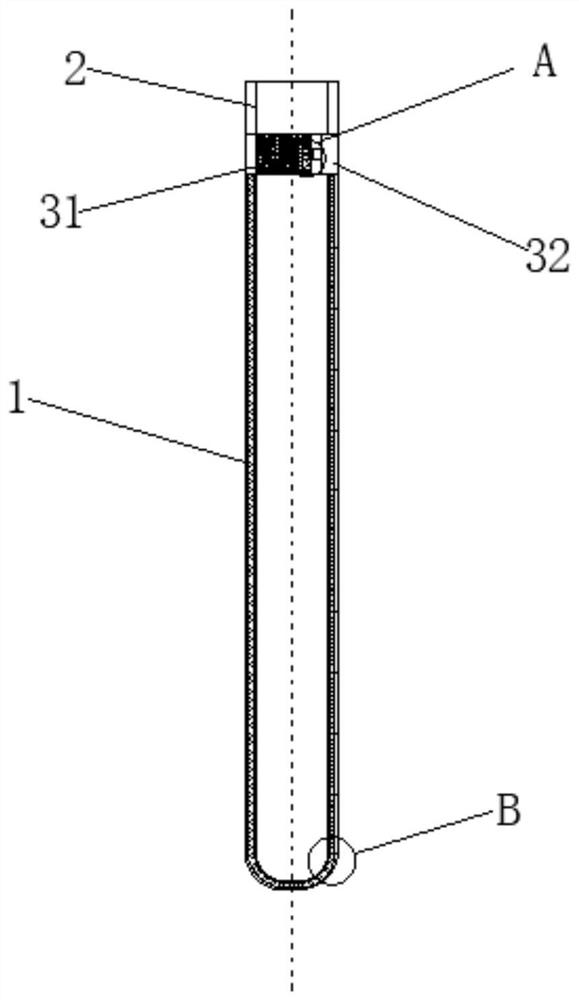

Protecting and fixing device for wound

ActiveCN102429769AAvoid tearingAvoid crackingEnemata/irrigatorsSurgical needlesInfusion catheterRelative displacement

The invention discloses a protecting and fixing device for wound, comprising at least one protecting and fixing layer with openings, wherein the protecting and fixing layer with openings is longitudinally provided with an opening for communicating the upper end face and the lower end face; the opening can enclose the wound therein so as to make the protecting and fixing layer with openings limit the wound tension and increase the mobile corrugation of the wounded skin. The invention can protect and fix the operation wound, the trauma wound or the catheter infusion wound into an opening which can limit the tension increase of the wound and the mobile corrugation of the surface skin of the wound and can prevent the wound from being torn and cracked and also avoid the damage for the wound due to the mobile corrugation and the surgical dressing of the wounded skin as well as the relative displacement frictions of the infusion catheter. Therefore, the invention fills the blank of current technology, which can enable the covered dressings to penetratively contact the secretion so as to absorb the exudate of the wound. Besides, the invention can prevent the foreign material contact anaphylaxis due to the wound contacting by compressing the dressing and the direct bonding of the catheter infusion wound and can prevent the re-injury of the wound caused by the synechia between the dressing and the wound secretion.

Owner:唐二虎 +2

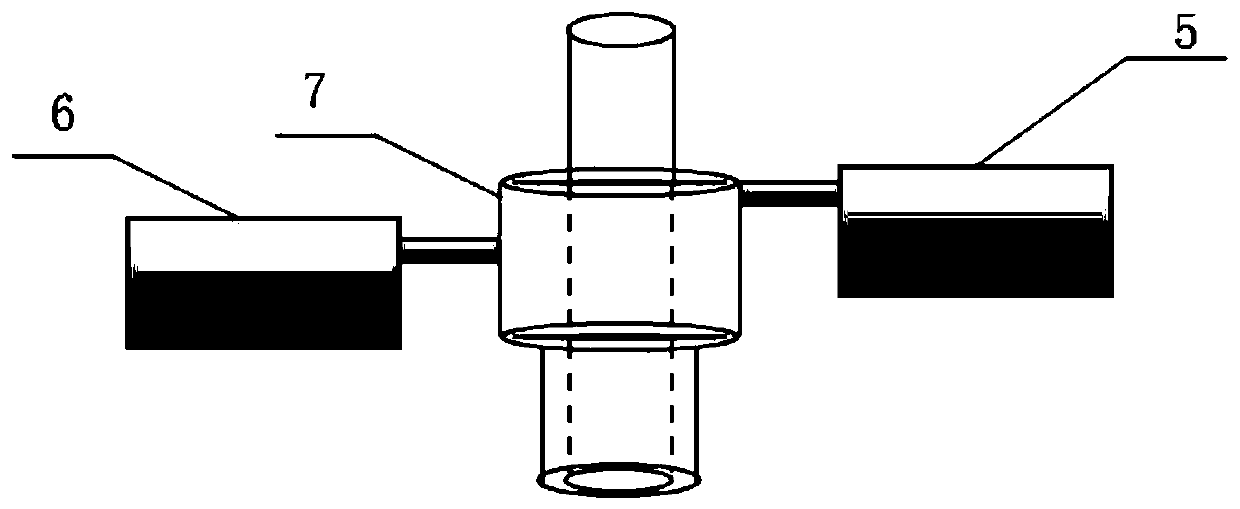

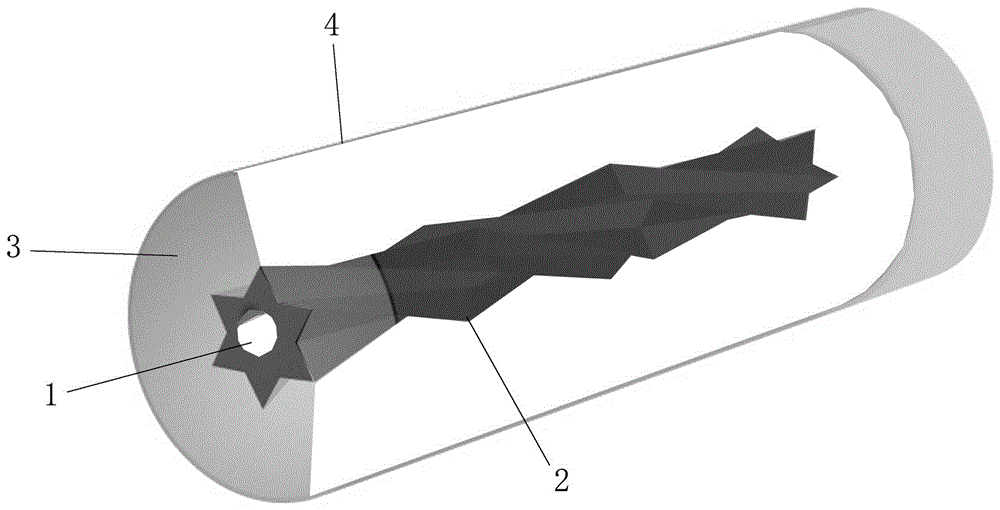

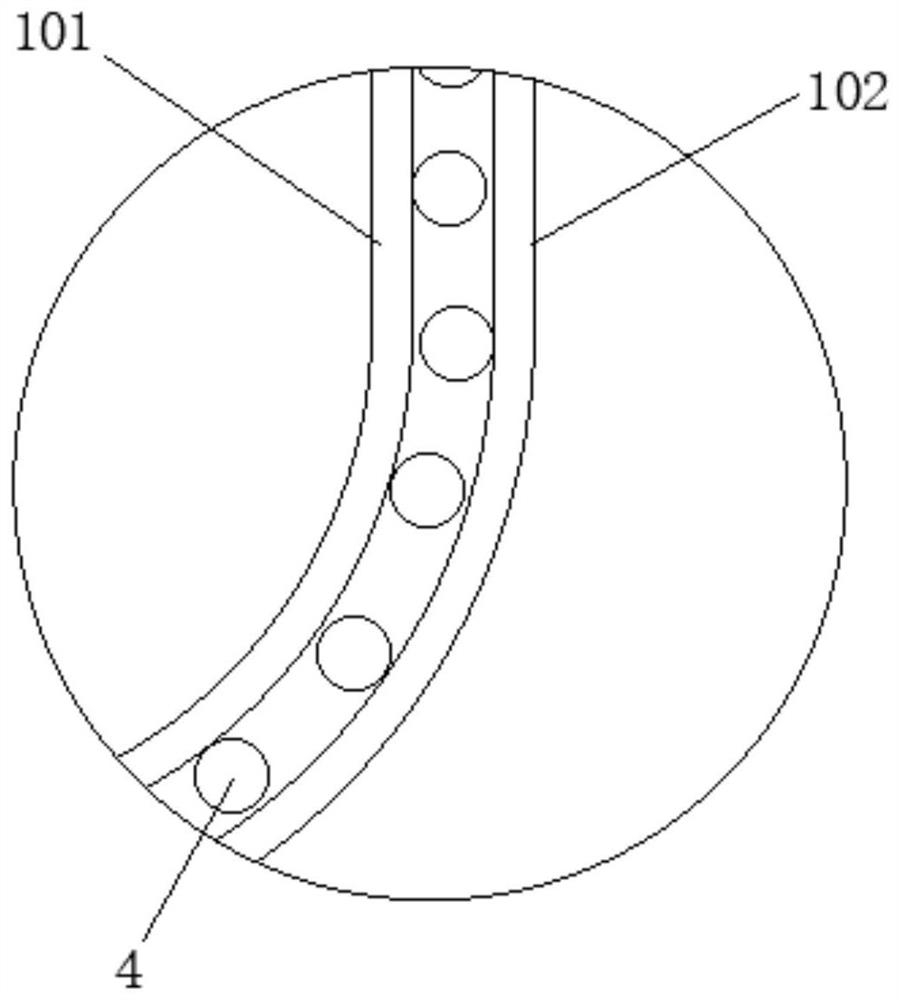

Gel-poly(lactide-co-glycolide) (PLGA) two-phase gradient transition cartilage-bone repair material and preparation thereof

InactiveCN103656745AGood biocompatibilityPromote degradationBone implantGlycidyl methacrylateLactide

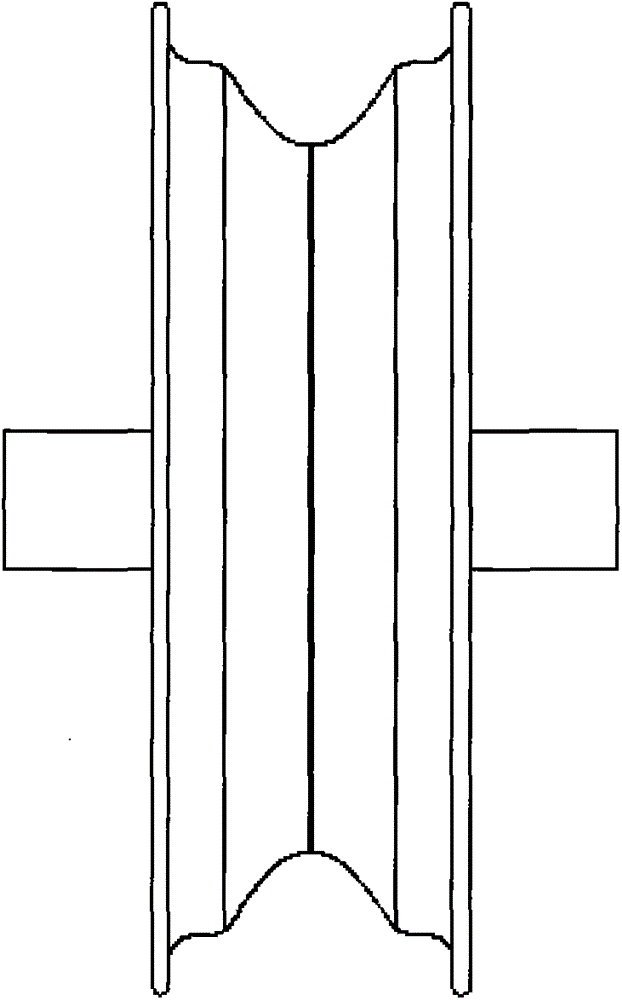

The invention discloses a gel-poly(lactide-co-glycolide) (PLGA) two-phase gradient transition cartilage-bone repair material and preparation thereof. The material is cylindrical and consists of an upper material and a lower material, wherein the upper material is glycidyl methacrylate-modified carboxymethyl chitosan and gelatin; the lower material is porous PLGA. The preparation process comprises the following steps: preparing a gelatin microsphere serving as a pore-forming agent into a PLGA porous scaffold of which one end face is a conical concave surface; preparing a gel solution by using the modified chitosan and modified gelatin; dripping the gel solution on the PLGA porous scaffold of the conical concave surface, inverting, performing ultraviolet light cross-linking to obtain the gel-PLGA two-phase gradient transition cartilage-bone repair material. The material has high biocompatibility and biodegradability, is in a two-phase gradient transition structure, is tightly combined without drop and is simple in preparation process.

Owner:TIANJIN UNIV

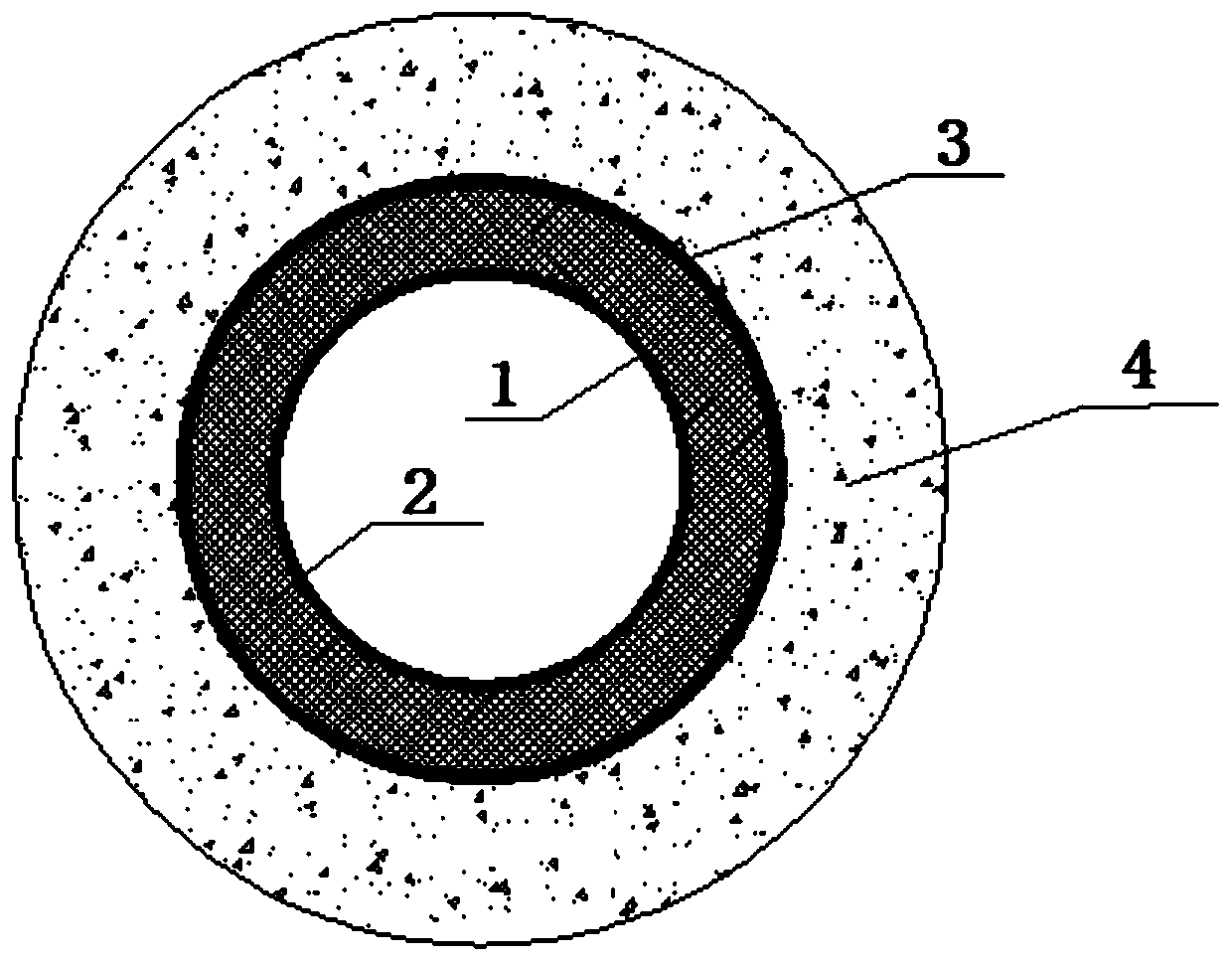

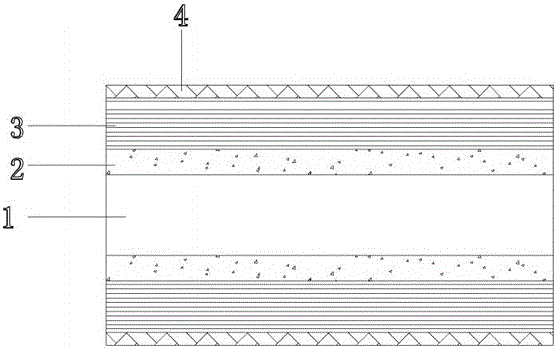

Fiber reinforced heat insulation composite hose and manufacturing method thereof

InactiveCN111578004AFlat surfaceRetention strengthThermal insulationSynthetic resin layered productsInsulation layerHot melt

The invention belongs to the technical field of composite hoses, and particularly relates to a fiber reinforced heat insulation composite hose and a manufacturing method thereof. The fiber reinforcedheat insulation composite hose comprises a reinforcing layer, wherein the reinforcing layer comprises an inner lining layer and a strip blank compounded on the outer surface of the inner lining layerin a hot melting manner, the outer surface of the strip blank is sequentially provided with a hot melt adhesive film layer and a heat insulation layer, and the heat insulation layer is made from a microcapsule foam material. One-step forming co-extrusion process is used for manufacturing. The fiber reinforced heat insulation composite hose has the beneficial effects that high strength and good heat and cold insulation effects are achieved while the light weight and softness of material are maintained, an all-in-one forming method is adopted, and simplicity, convenience and efficiency are achieved.

Owner:ZHONG YU HOSES TECH CO LTD

Preparation method of bamboo fiber molding composite

ActiveCN111516073AEfficient use ofIncrease the gapRadiation/waves wood treatmentPressure wood treatmentFiberCeramic materials

The invention provides a preparation method of a bamboo fiber molding composite. The method comprises the steps that after bamboo chips are ground into a loose state, the bamboo chips are soaked intoa nano calcium carbonate solution, a chelating agent is added, flash-explosion treatment is carried out, and modified bamboo fiber crude products are obtained; the residual solution is filtered to obtain bamboo basic structure crude products; the bamboo fiber crude products are soaked into a nano calcium carbonate solution to be ultrasonically treated, and modified bamboo fibers are obtained; theresidual solution is filtered to obtain bamboo basic structure crude products; the bamboo basic structure crude products obtained in the two times are combined, washing and airing are carried out, andbamboo basic structures are obtained; and the bamboo basic structures are soaked into water, a thickening agent is added, stirring and filtering are carried out, modified bamboo basic structures areobtained, the dried modified bamboo fibers and the modified bamboo basic structures are mixed and subjected to mold pressing, and the bamboo fiber molding composite is obtained. The bamboo fiber molding composite is good in uniformity and high in fiber yield, the bamboo basic structures can be effectively utilized, and efficient utilization of bamboo is achieved.

Owner:ZHEJIANG FORESTRY ACAD

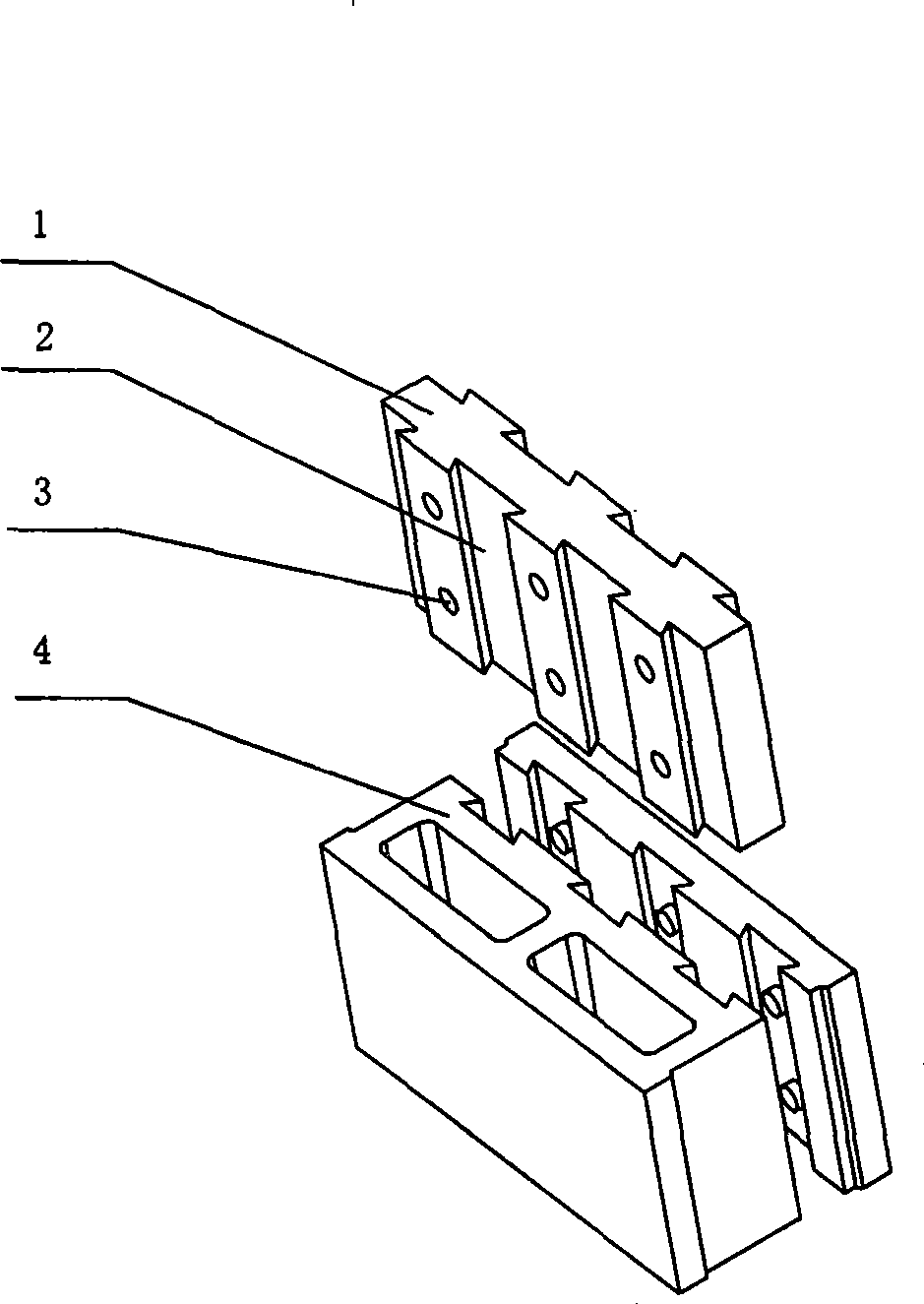

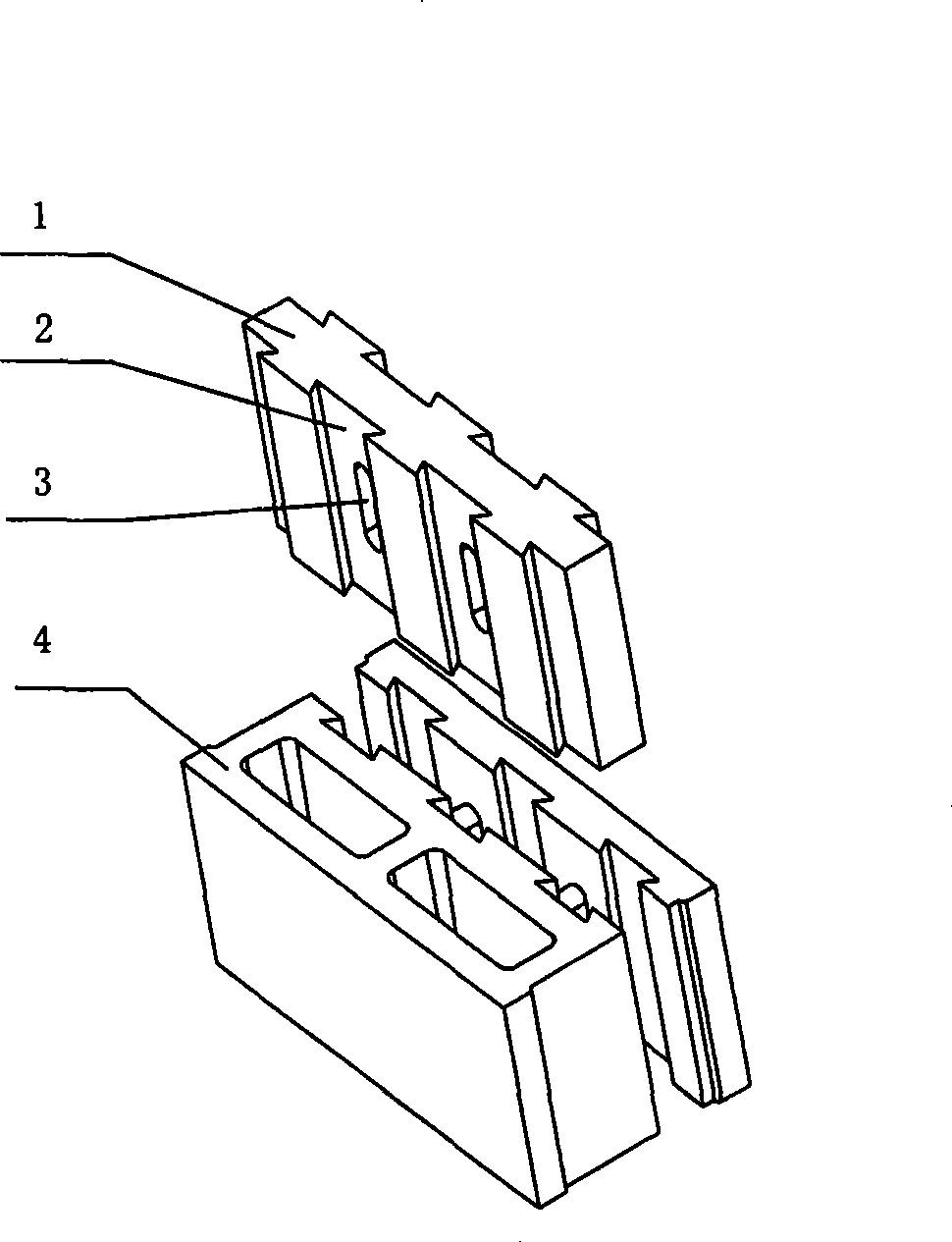

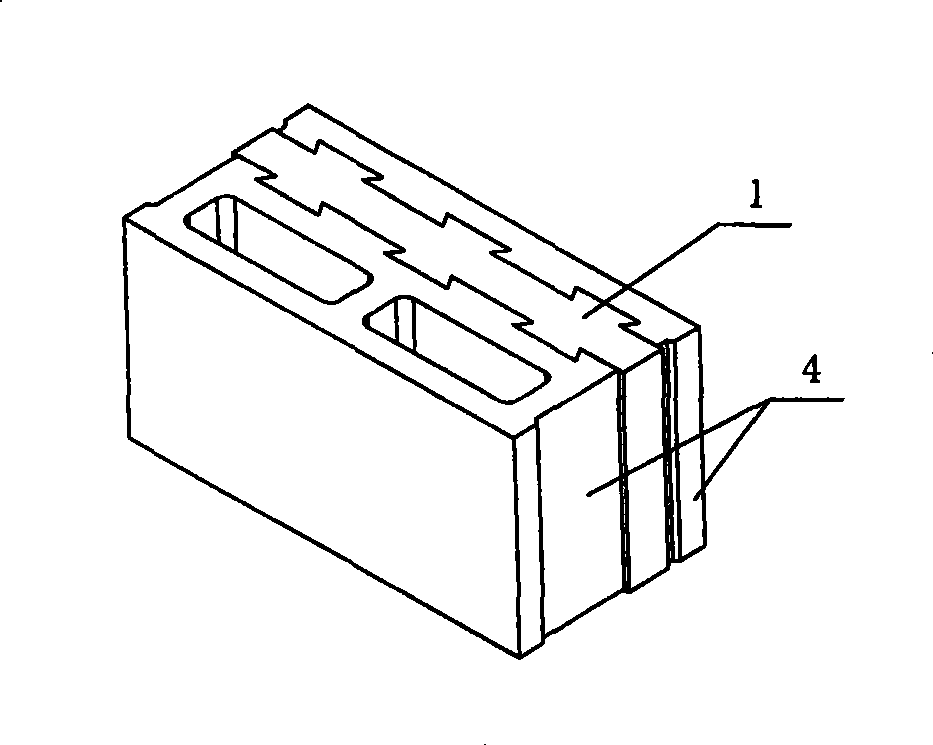

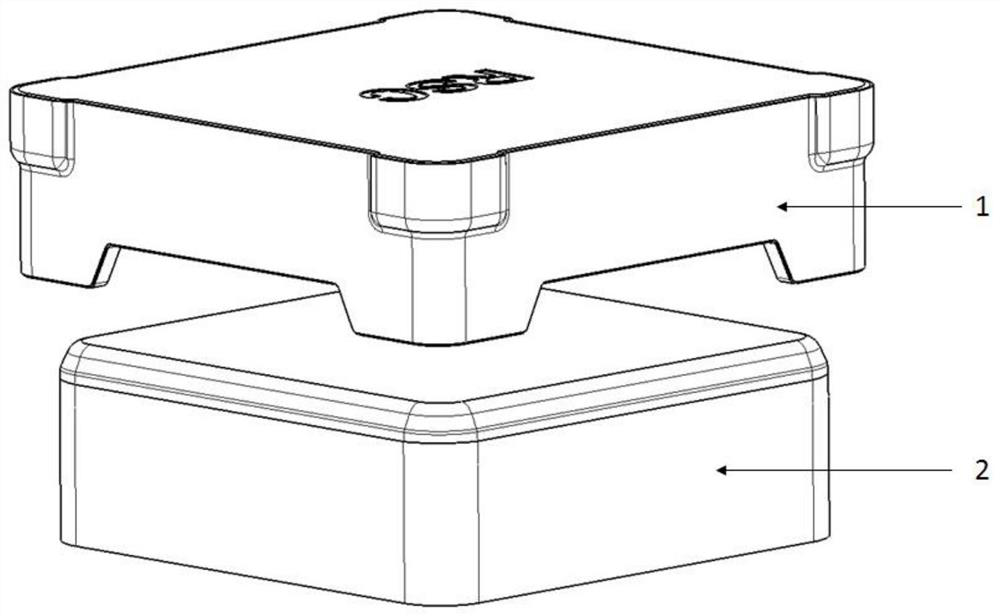

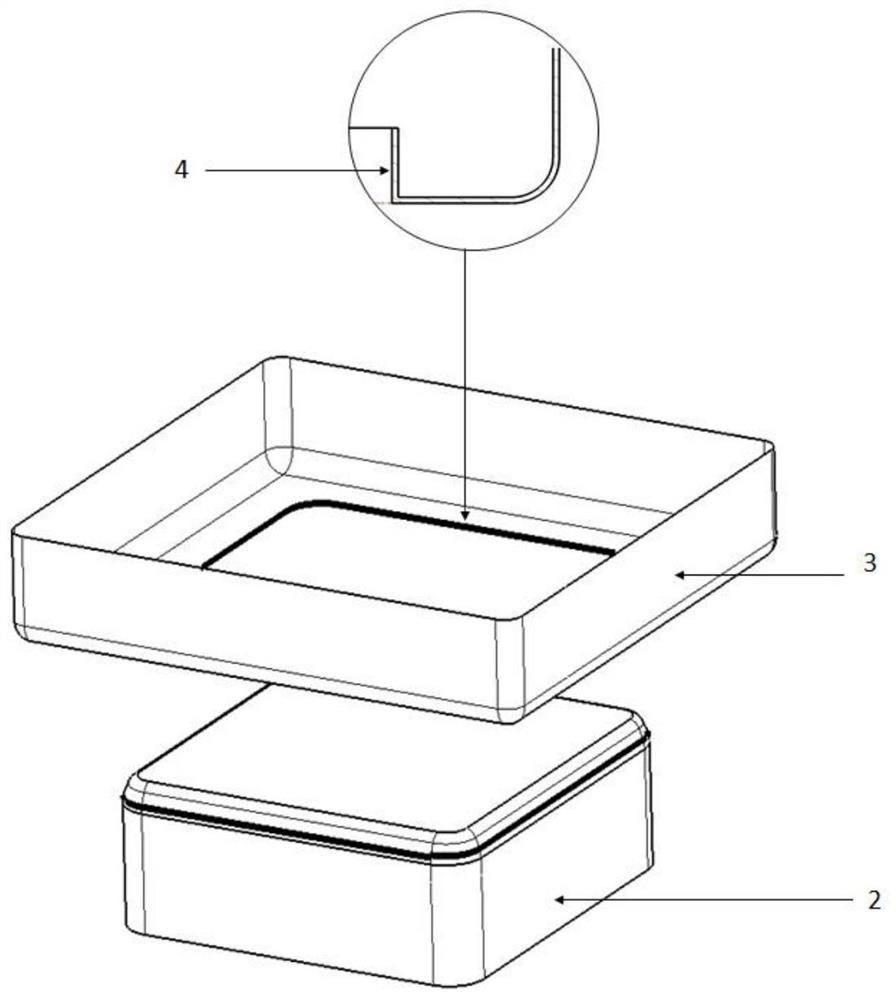

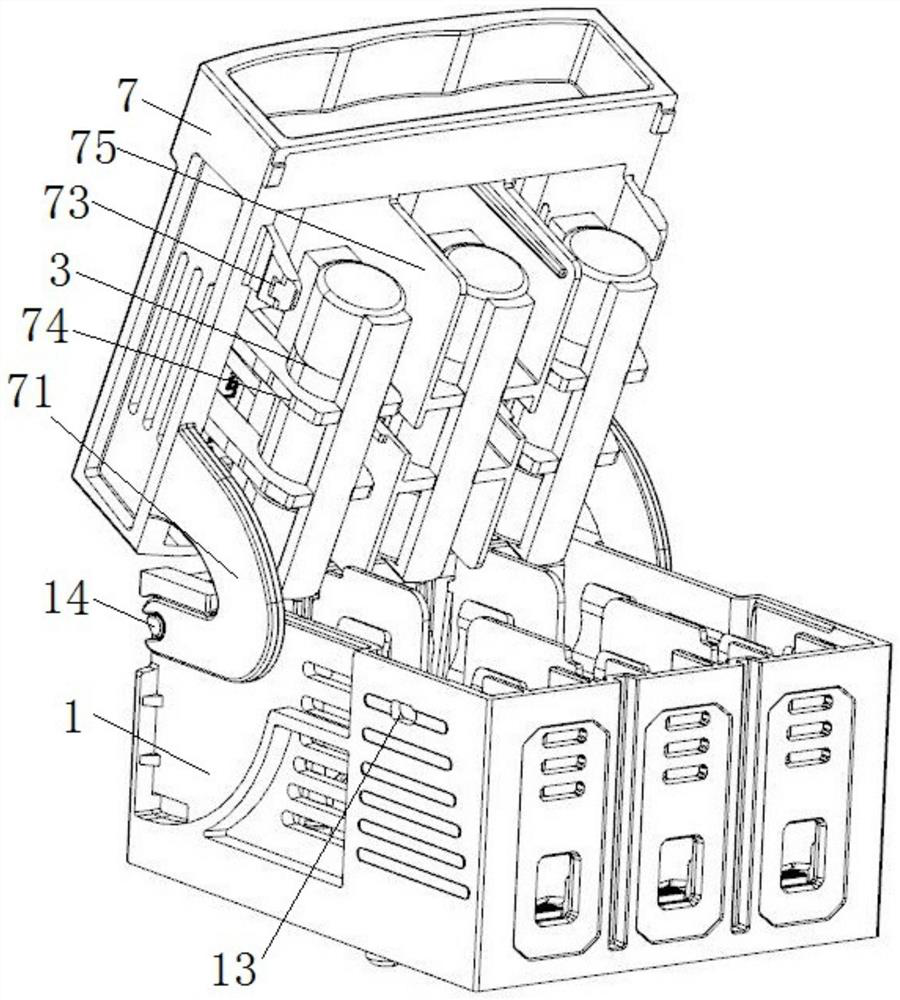

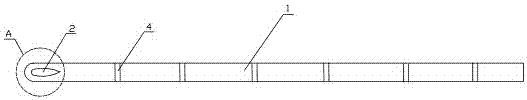

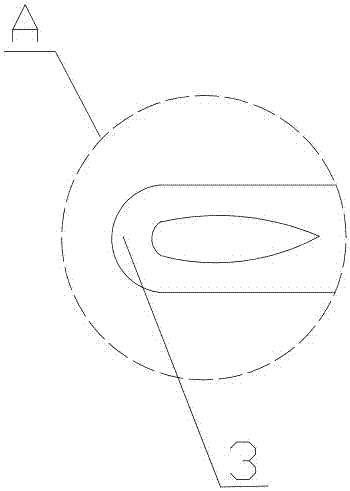

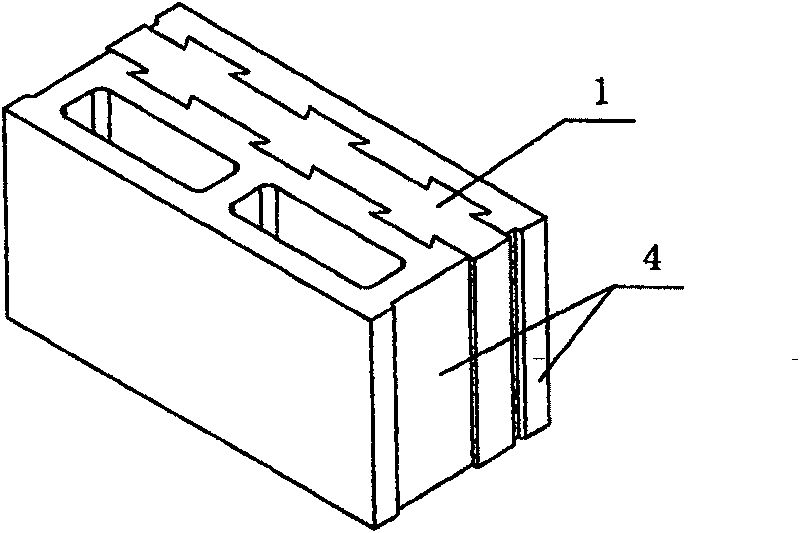

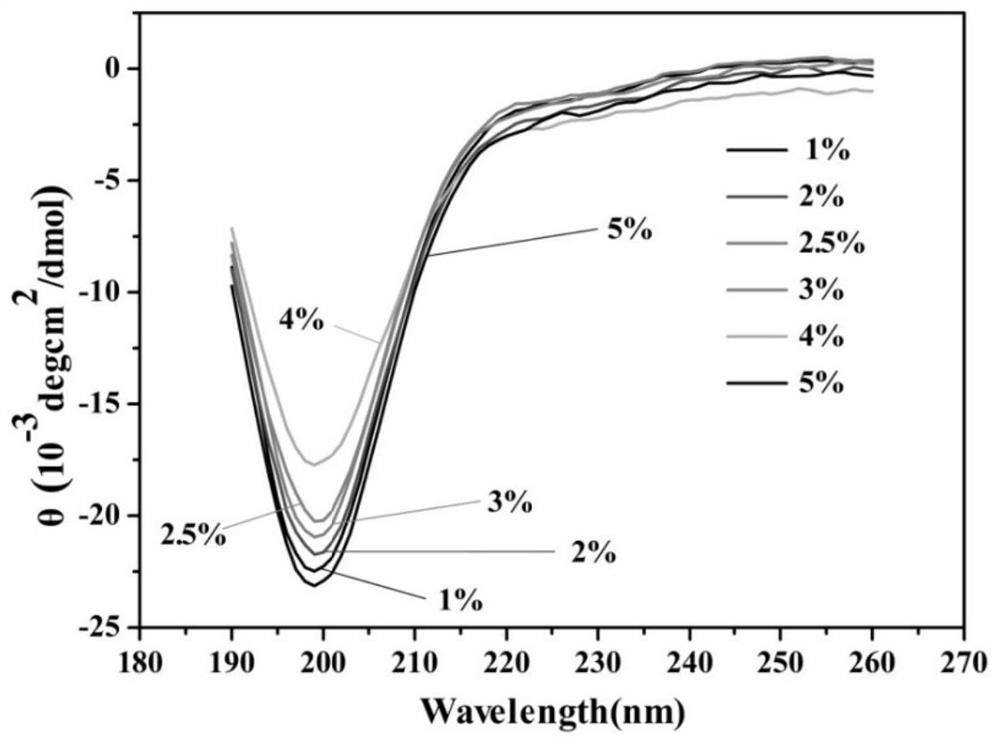

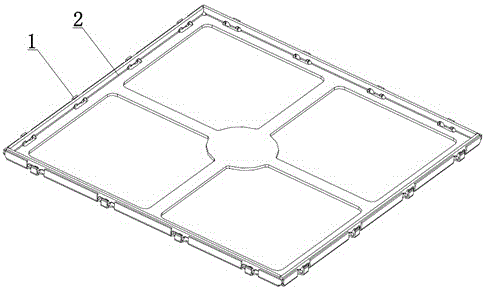

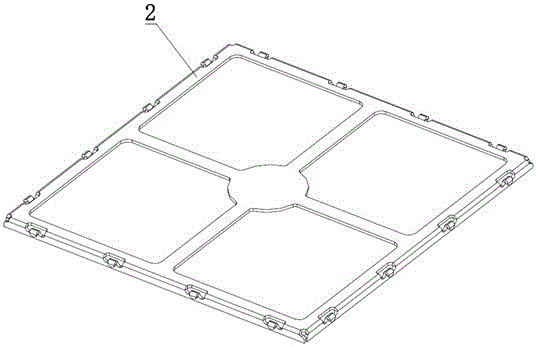

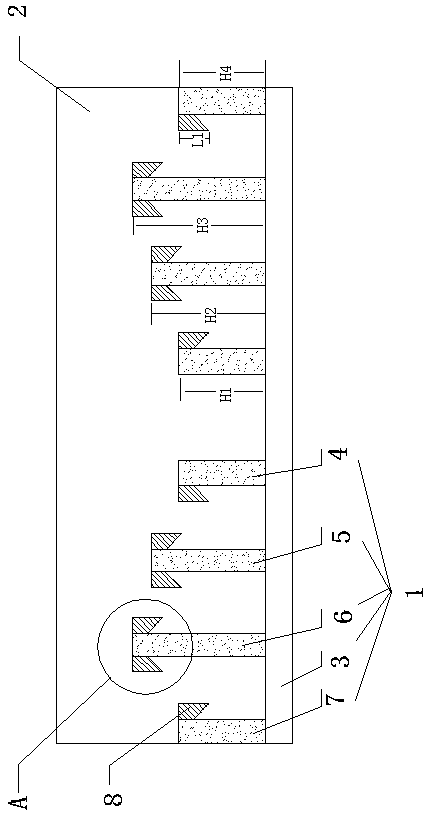

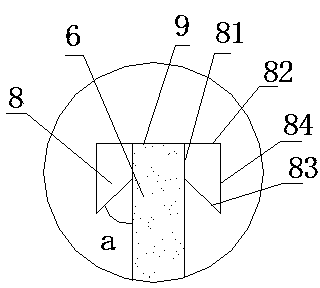

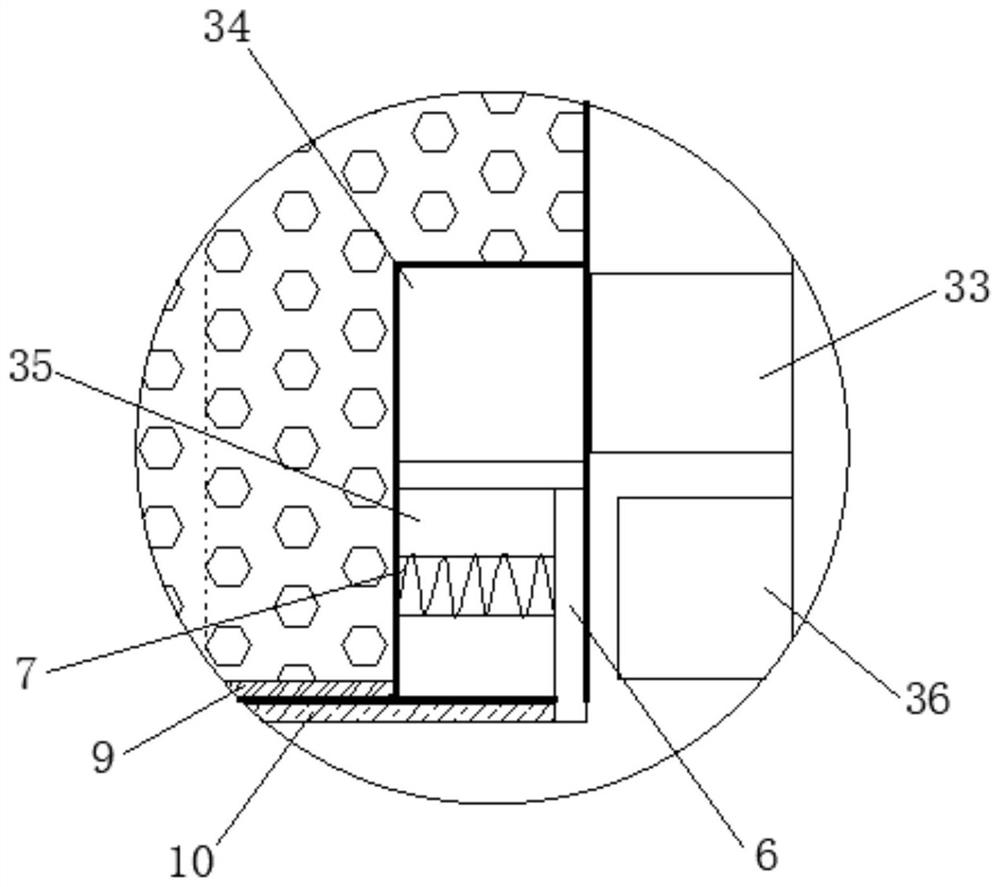

Thermal insulation concrete brick and special synchronous core-building apparatus

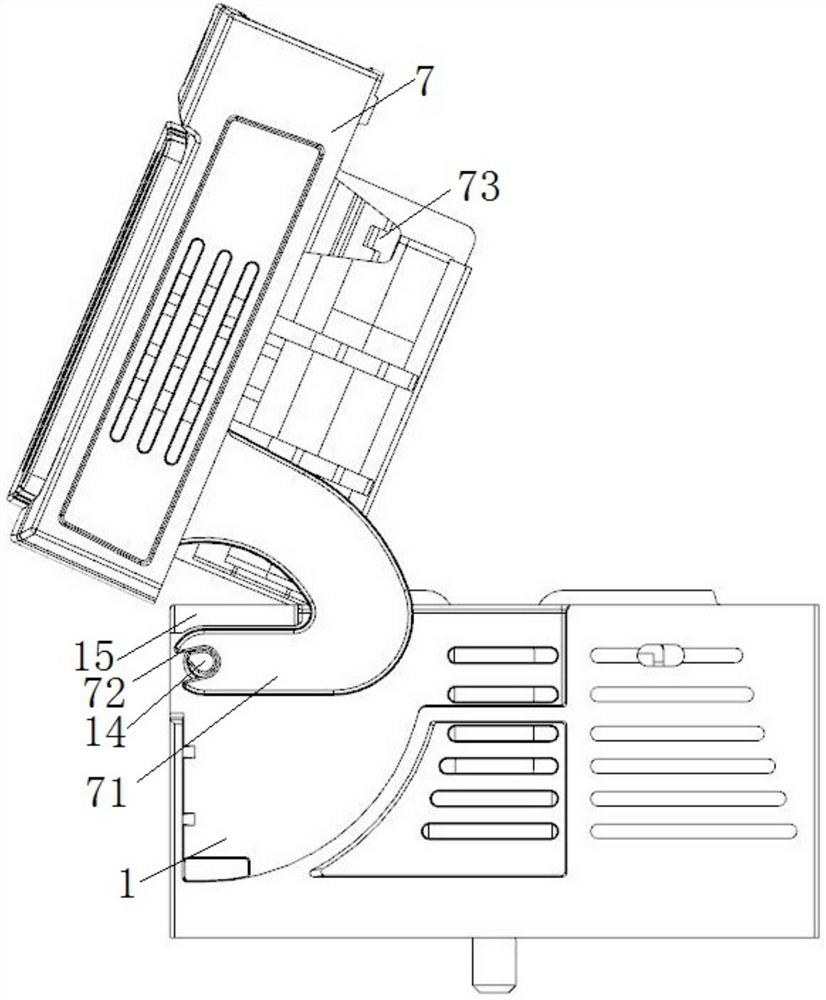

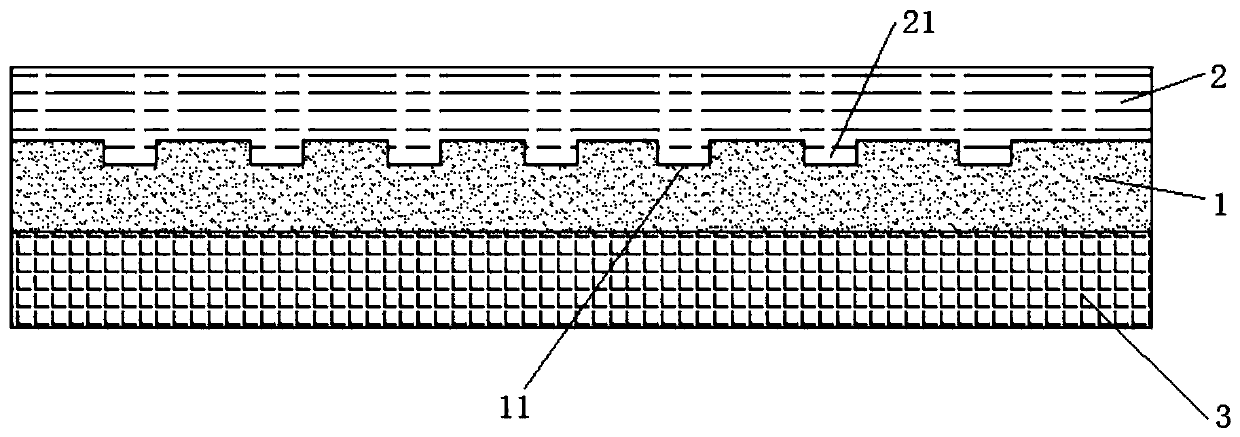

InactiveCN101387149ANot easy to separate and fall offImprove bindingConstruction materialCeramic shaping apparatusBrickThermal insulation

The invention discloses a heat preservation concrete block and a special synchronous core filling machine thereof. The invention relates to a heat preservation concrete block and a core filling device for processing the same. Surfaces of two sides of a heat preservation core layer or a bottom surface of a dovetail groove are provided with concave pits, respectively; and the heat preservation layer are connected with concrete layers at two sides through the dovetail groove and the concave pits. The synchronous core filling device is arranged at the rear part of a vibrating table of a block forming machine and consists of a machine frame, guide rails, a trolley, a driving device of the trolley, and a carrier, a supporting plate, rails of the supporting plate, a controller and a trolley position sensor which are fixedly connected on the trolley, wherein the rails of the supporting plate is as high as or higher than the vibrating table of the block forming machine, the supporting plate is placed on the rails of the supporting plate. The carrier is arranged on the upper part of the front end of the trolley, and a pushing device for the supporting device is arranged on the lower part of the front end of the trolley. The trolley position sensor and the driving device of the trolley are connected with the controller. The heat preservation concrete block is bonded firmly and has the advantages of good heat preservation effect, high strength, low processing cost and high processing efficiency.

Owner:扬州威奥重工机械有限公司

Method for processing microstructure of silicon and metal composite material

InactiveCN102167282AHigh dimensional accuracyNot easy to separate and fall offDecorative surface effectsChemical vapor deposition coatingEtchingSilicon chip

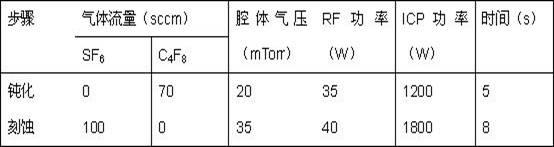

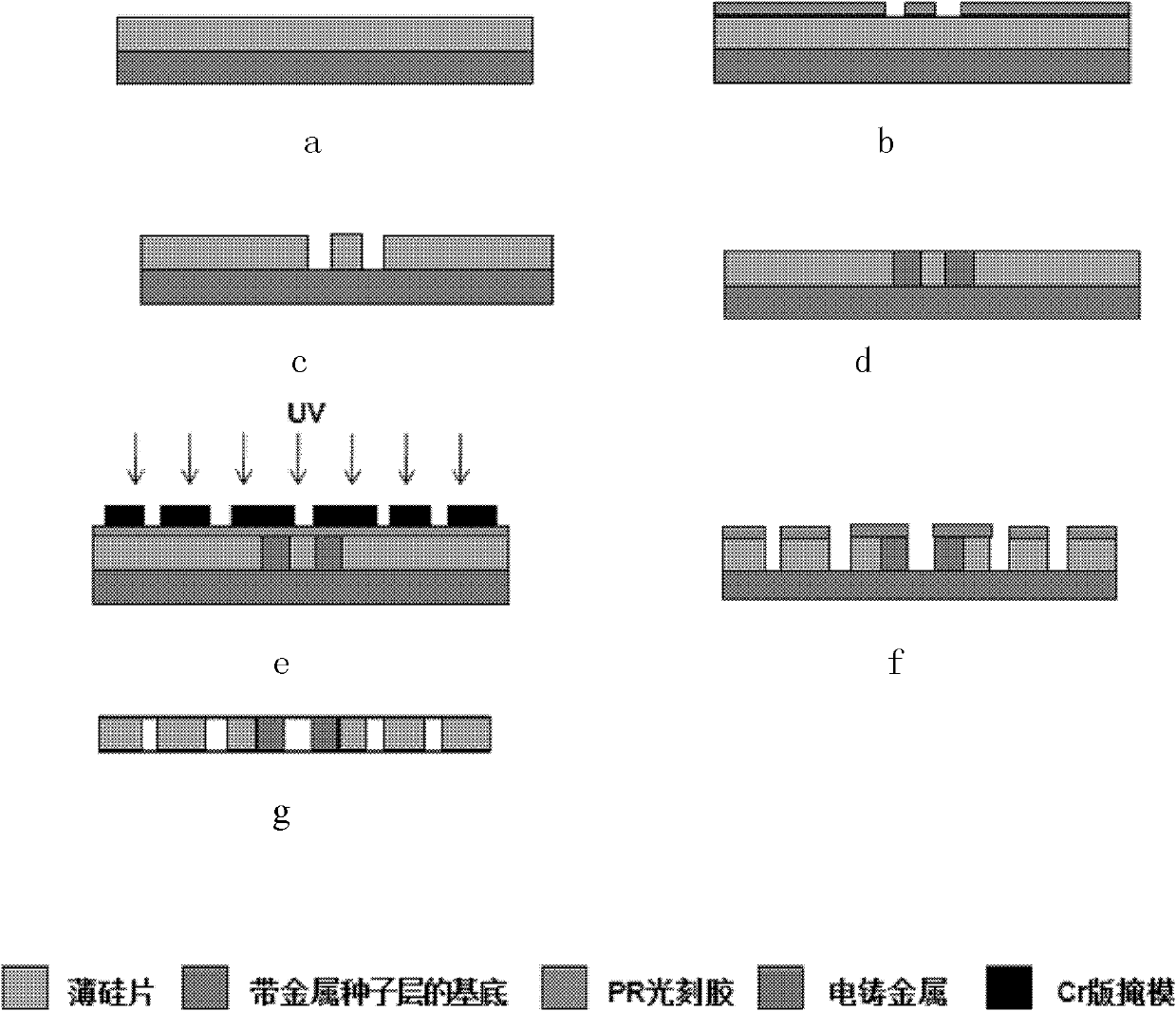

The invention discloses a method for processing a microstructure of a silicon and metal composite material. The method comprises the following steps of: 1, performing congruent melting and bonding on a silicon wafer and a metal electroforming seed layer on a silicon substrate; 2, performing photoetching on an AZ short pimp electroforming metal pattern; 3, performing deep etching on a first layer of silicon structure; 4, filling a structure in electroforming metal; 5, performing photoetching on an AZ short pimp silicon structure pattern; 6, performing deep etching on a second layer of silicon structure; and 7, removing photoresist and separating the substrate to release the micro structure of the silicon and metal composite material. The method has the advantages that: the functional silicon wafer is bonded on the silicon substrate with the metal seed layer, etching is performed by using a reaction ion coupled dry method deep etching technology, a metal structure is electroformed, and other silicon structures are etched; the micro structure obtained by the method has high size accuracy, and the electroforming metal has a perfect structure; the silicon side wall which is subjected to deep etching has scallop-type strips, so that the electroformed metal structure and the silicon structure are meshed with each other and are not easy to separate and drop; moreover, the deep etching and electroforming process is adopted, so the repeatability is high.

Owner:TIANJIN SEAGULL WATCH CO LTD +1

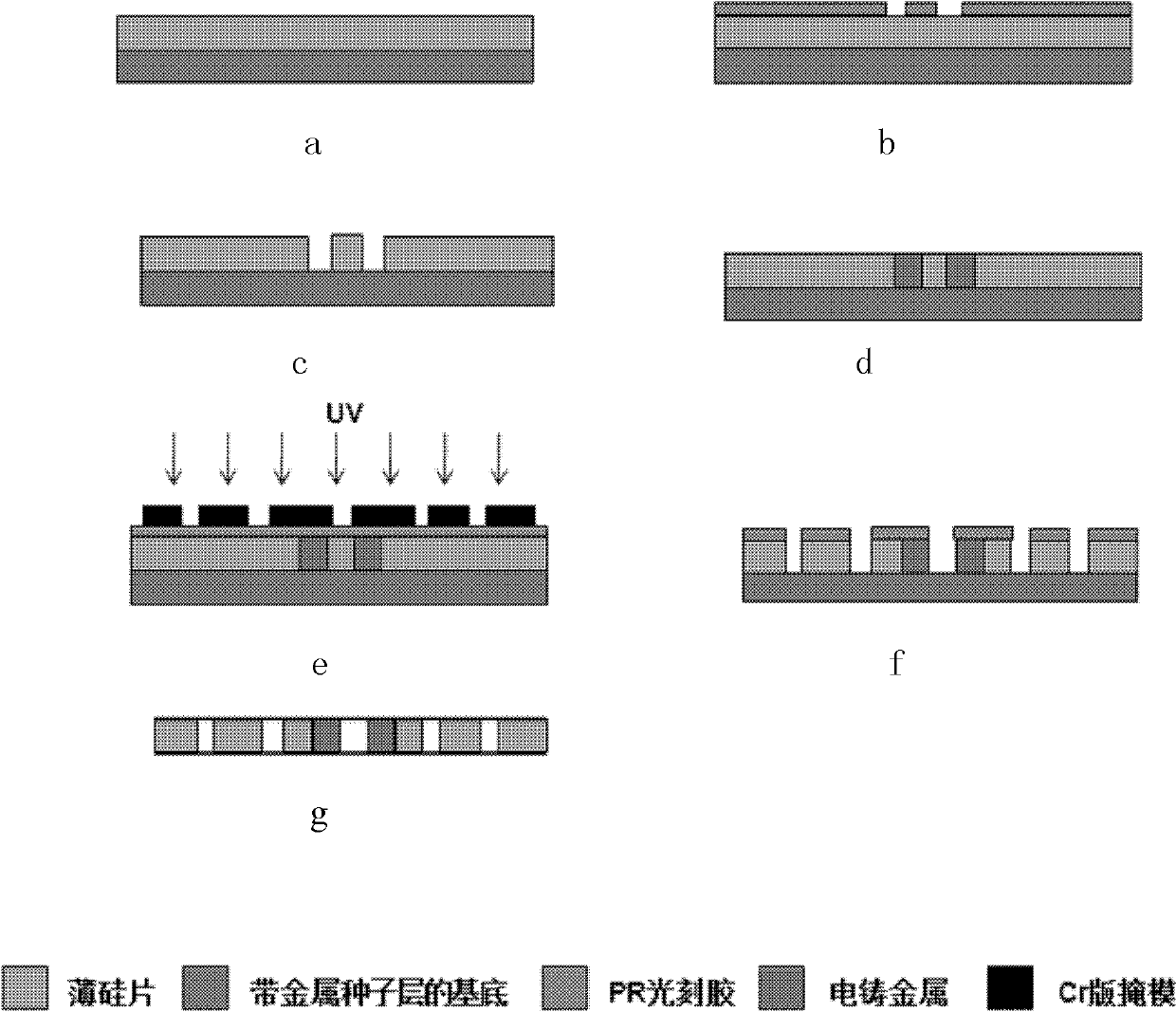

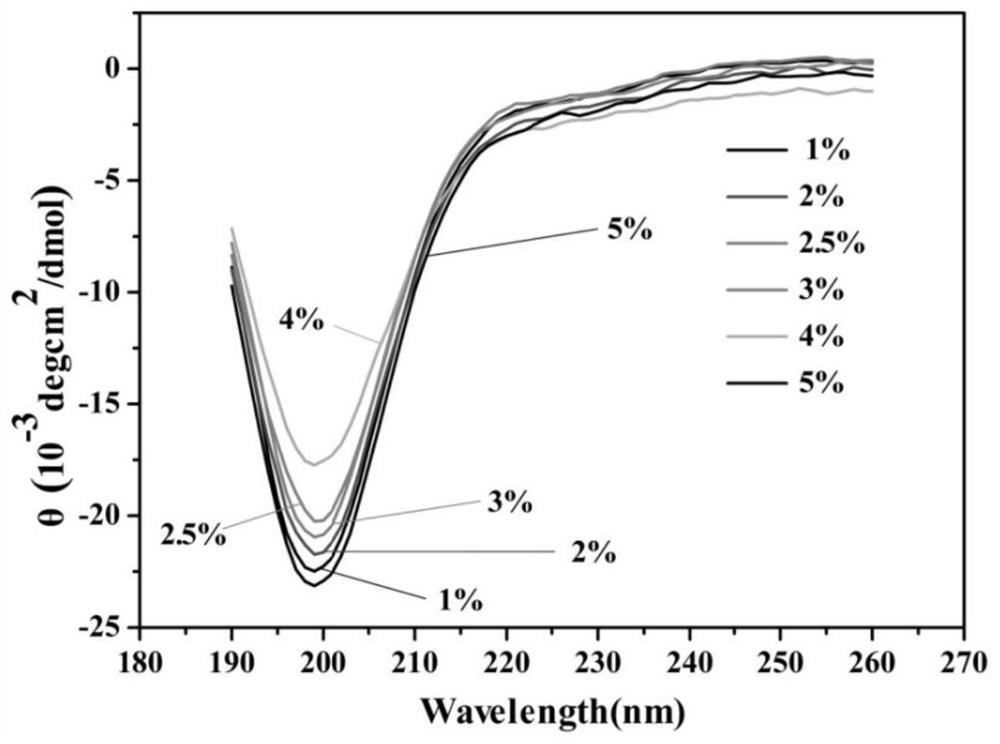

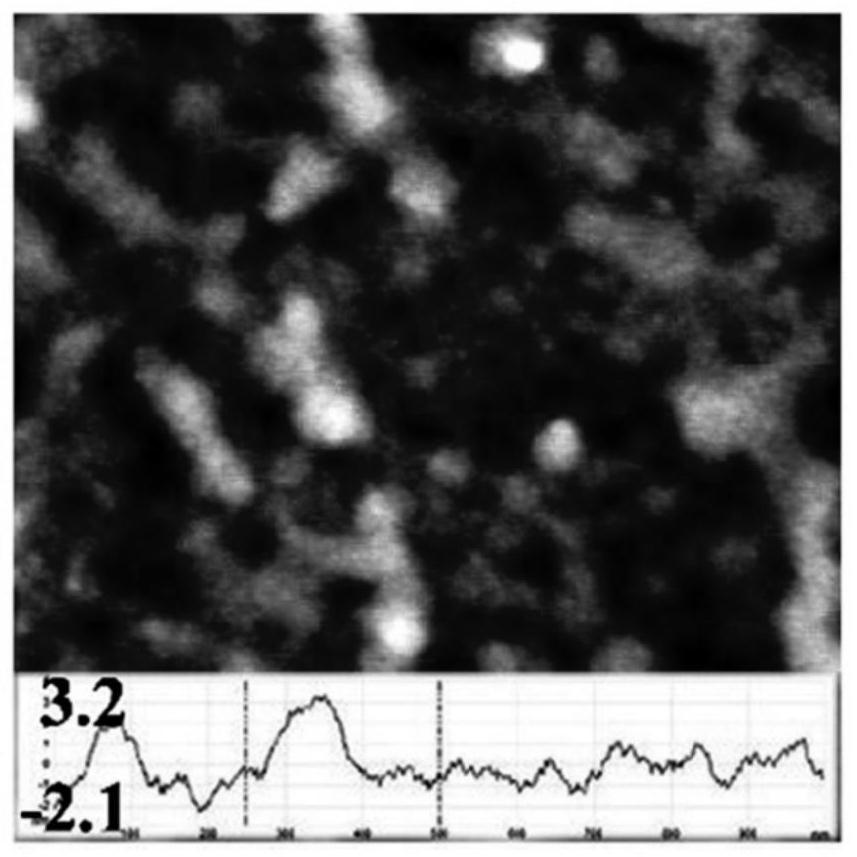

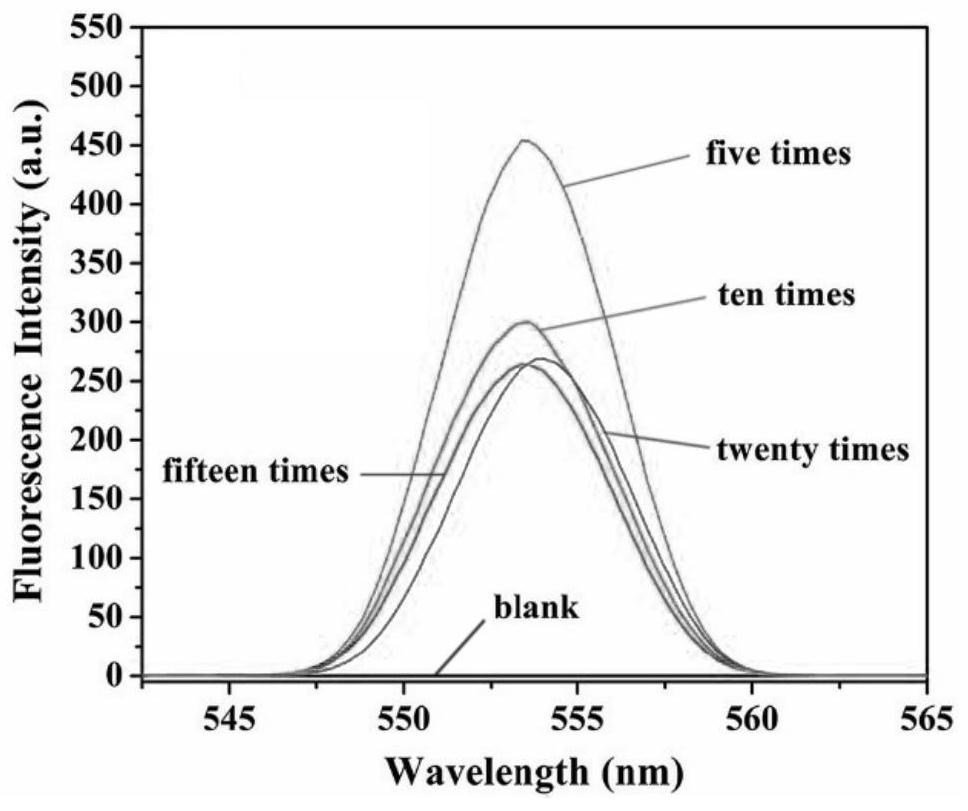

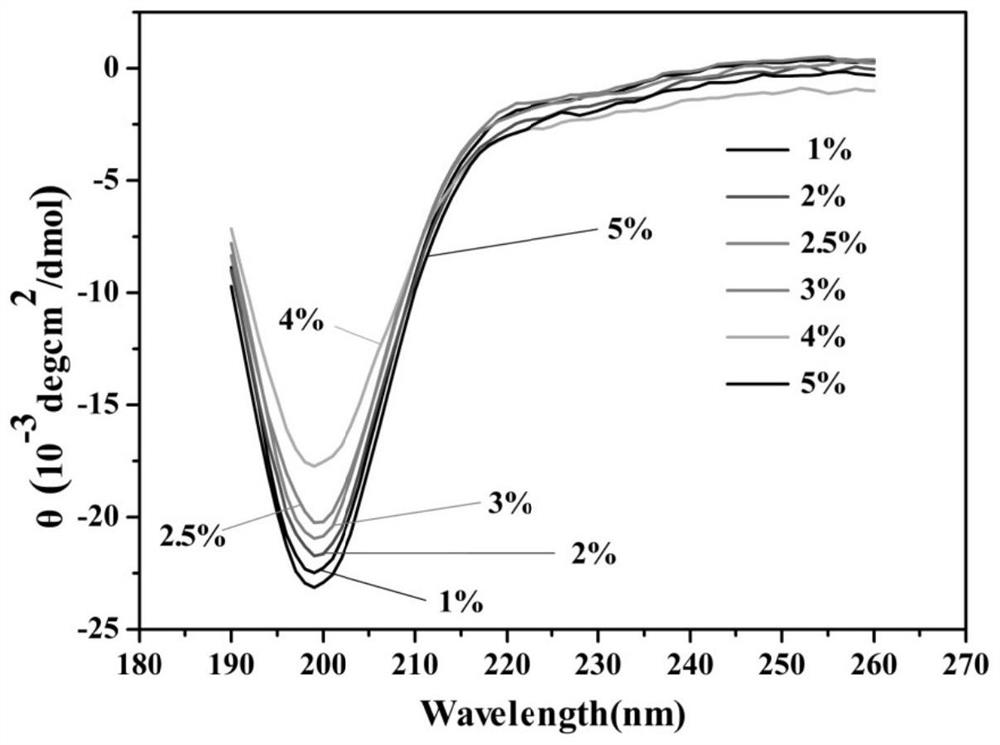

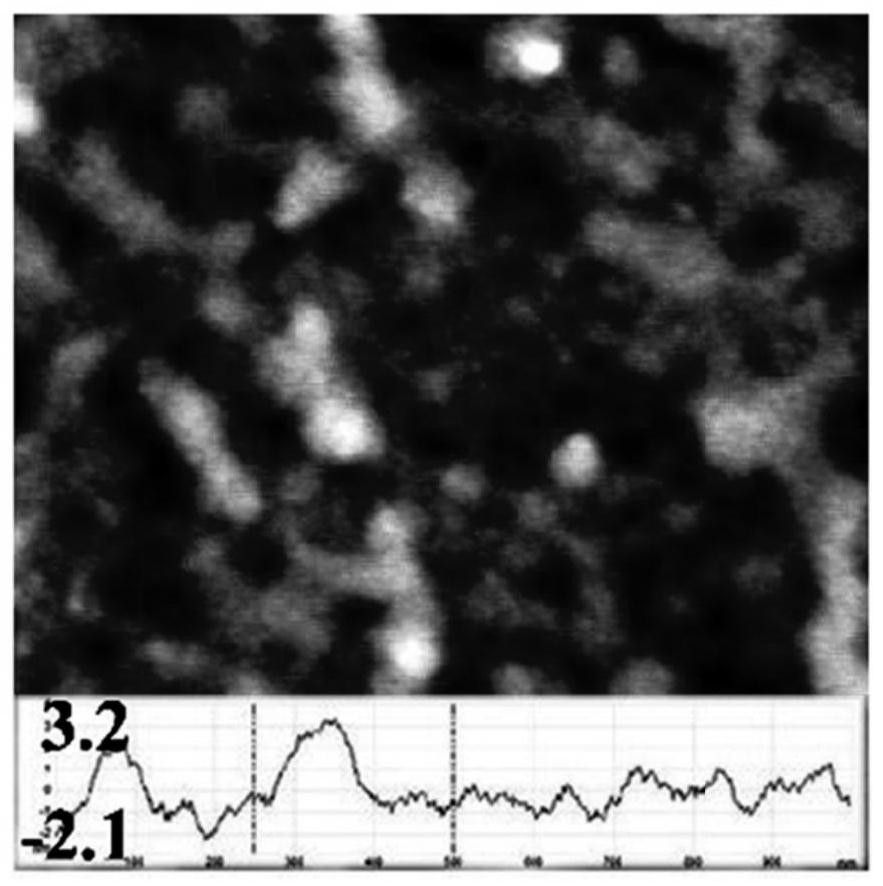

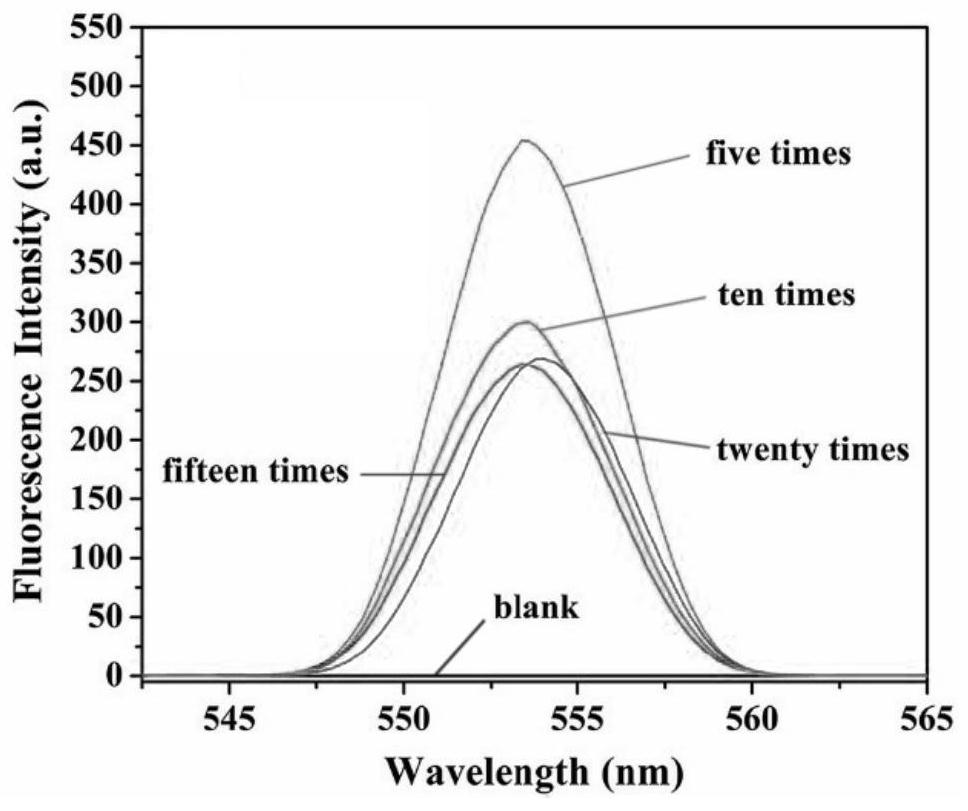

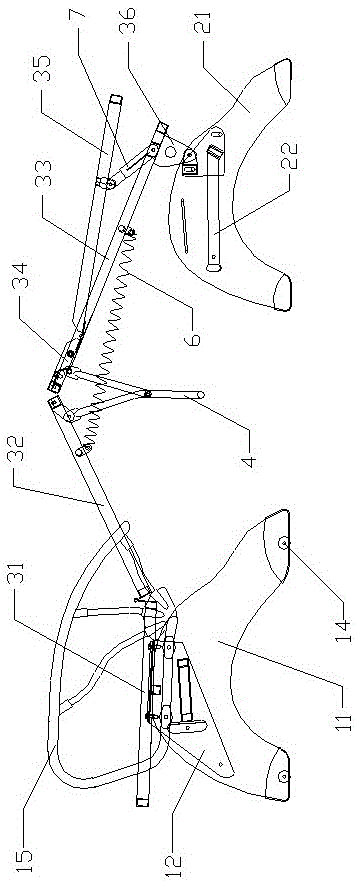

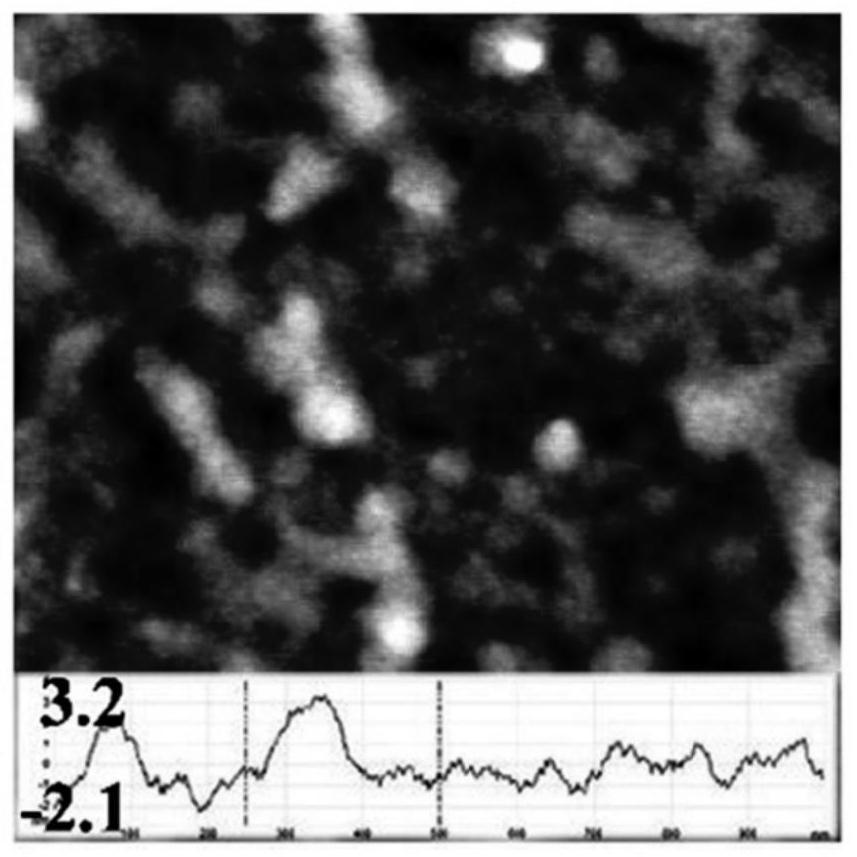

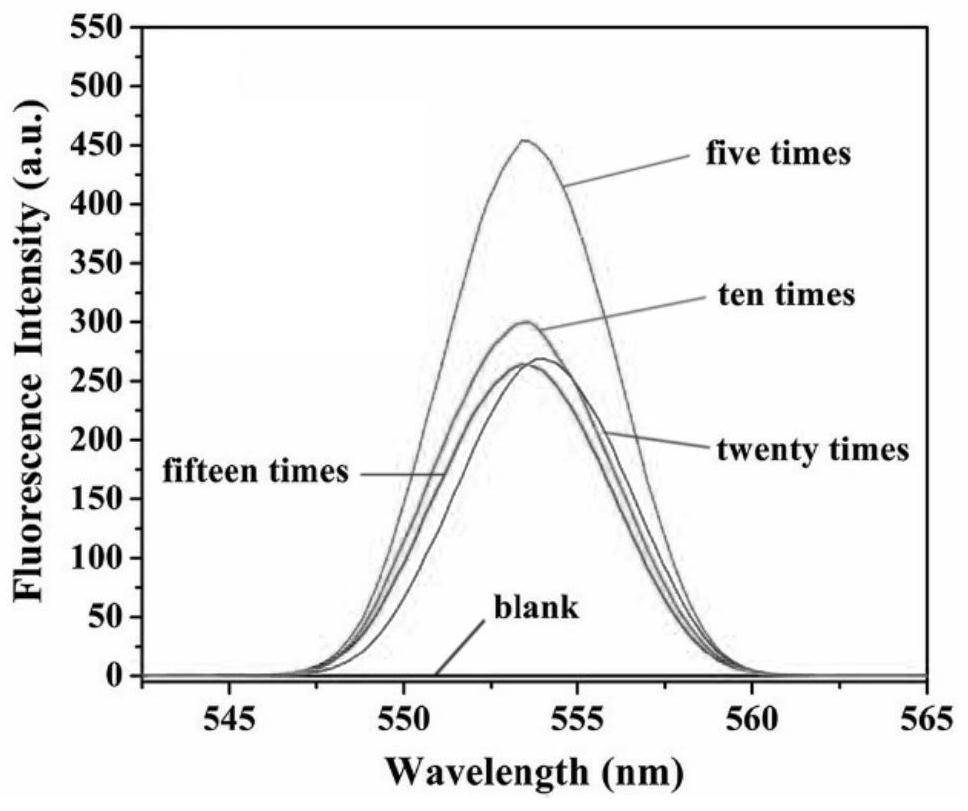

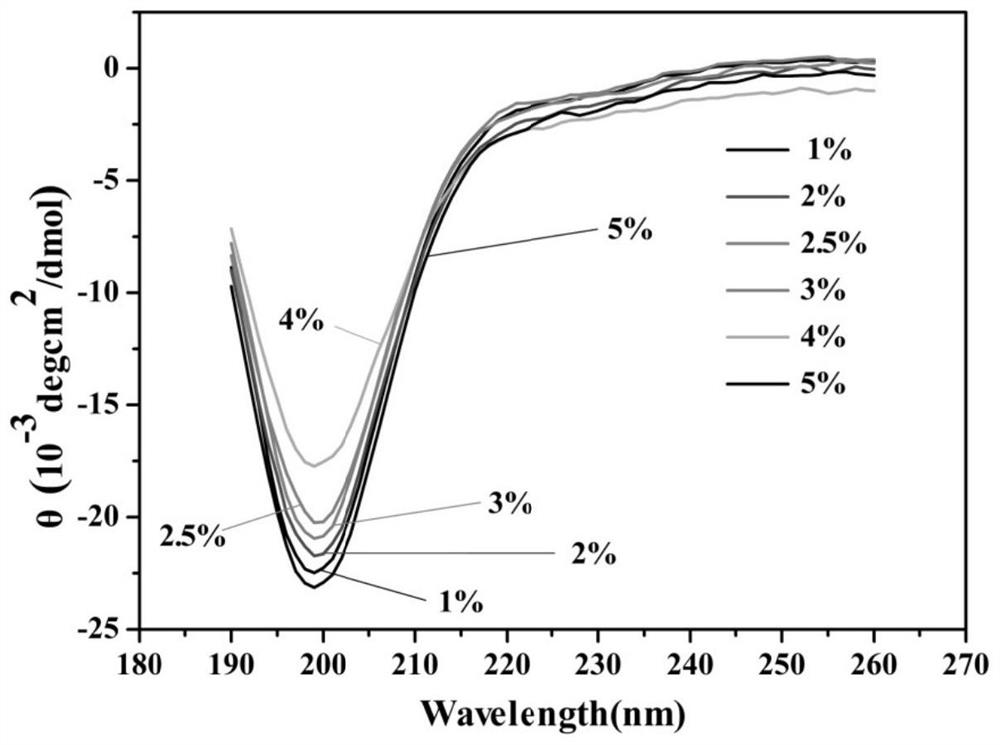

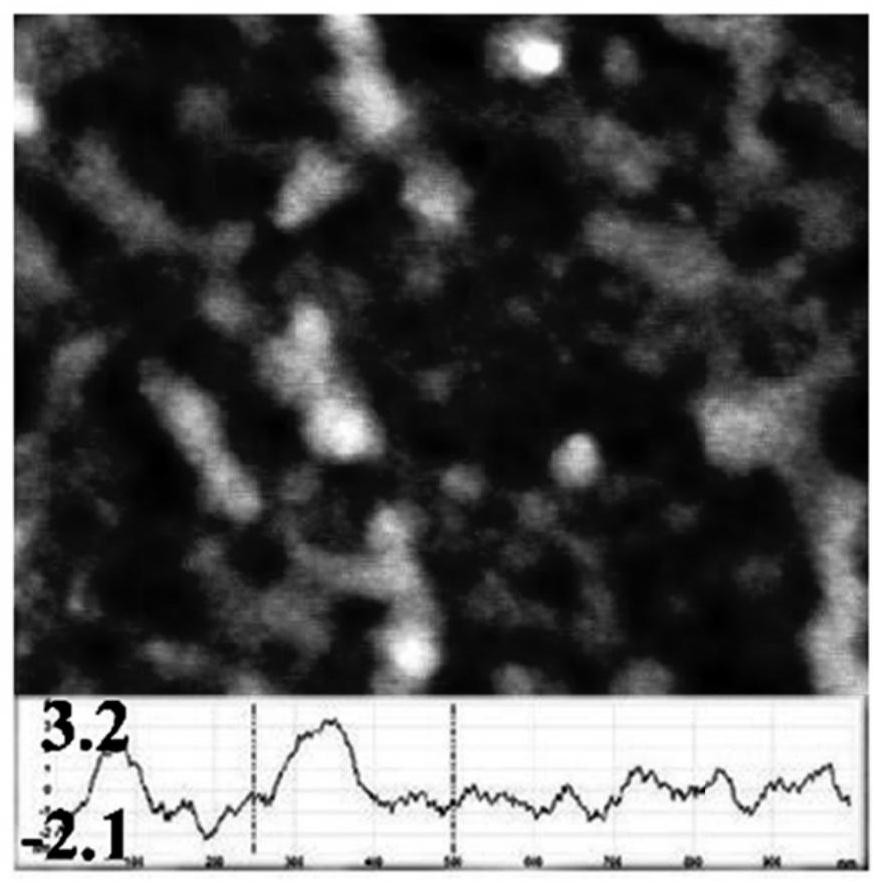

Polypeptide monolayer film with 7% of exposure quantity of primary amino groups as well as preparation method and application of polypeptide monolayer film

ActiveCN111671970AImprove stabilityGood adhesionTissue regenerationCoatingsThin membraneBiomedical engineering

The present invention provides a polypeptide monolayer film with 7% of exposure quantity of primary amino groups as well as a preparation method and application of the polypeptide monolayer film. Thepolypeptide is composed of a polypeptide molecule with the molecular weight of (1.48+ / -0.2)*105 g / mol, wherein the thickness of a monolayer film is 8.9+ / -0.1 nm, the primary amino group exposure of the surface of the film is 7.0+ / -0.2%, the Zeta potential of the polypeptide monolayer film is 0.76+ / -0.1 mV; and the contact angle of the film is 48+ / -1 DEG. The polypeptide monolayer film provided bythe present invention has good stability, may be applied as a coating material on the surface of an oral implant and may carry antibiotics and antibacterial drugs and stably release the antibiotics and the antibacterial drugs, the exposure quantity of the primary amino groups on the surface of the film is precisely controlled at 6.0+ / -0.3%, a local medicine carrying coating of the polypeptide monolayer film has the advantages such as little toxic and side effects to human bodies and strong antibacterial property, and the polypeptide monolayer film is uniform and tight in combination with a pure titanium material and not easy to separate and fall off.

Owner:QILU UNIV OF TECH

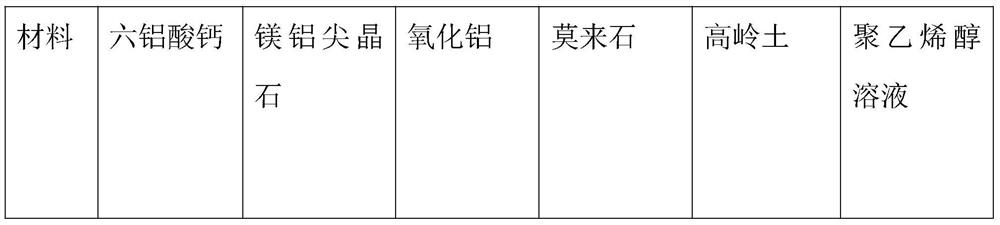

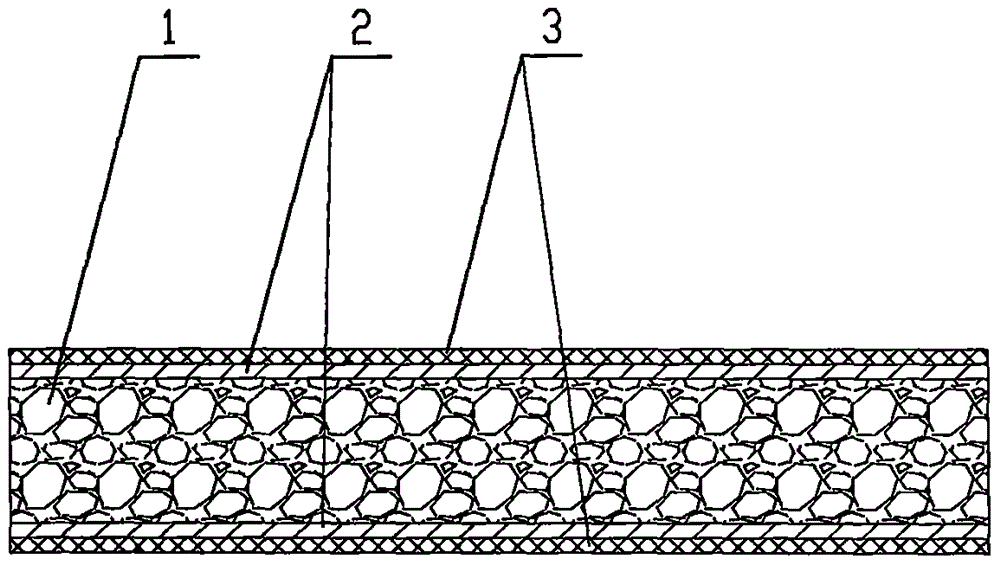

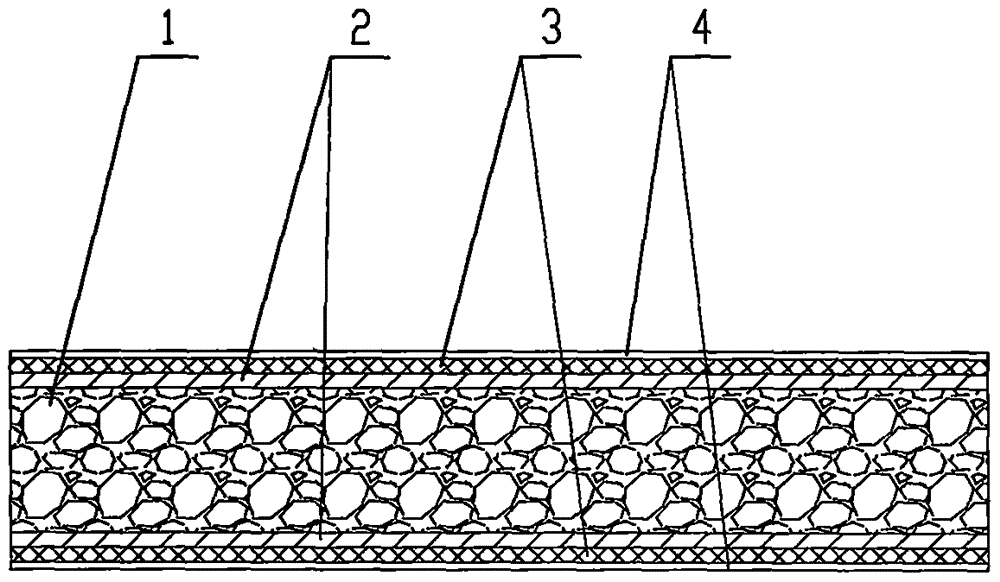

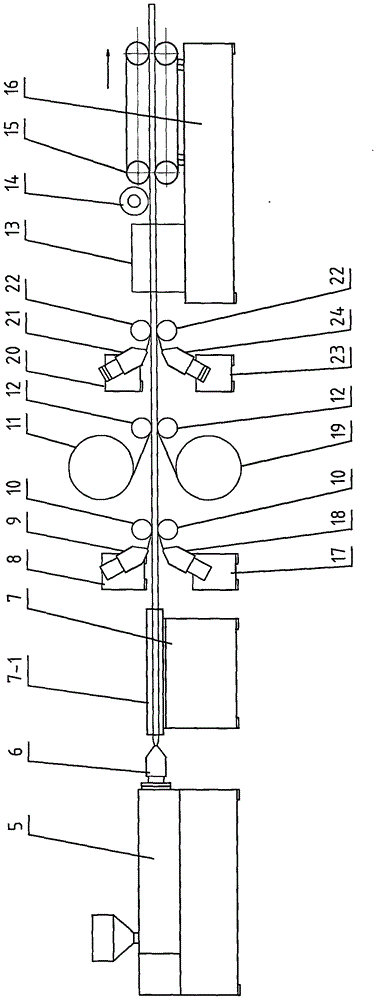

Sagger containing calcium hexaluminate composite layer and preparation method of sagger

The invention discloses a sagger containing a calcium hexaluminate composite layer and a preparation method of the sagger. The sagger containing the calcium hexaluminate composite layer is a composite layer sagger and comprises a base layer and the calcium hexaluminate composite layer, and when the sagger is prepared, a simple tool for applying composite layer powder is adopted, the powder is uniformly applied to the inner surface of the sagger, the calcium hexaluminate composite layer powder and the matrix layer powder are molded into a blank in one step in a mold pressing mode, and then the blank is fired and molded in a high-temperature kiln. The sagger has the beneficial effects that calcium hexaluminate, magnesium aluminate spinel, aluminum oxide and mullite in the calcium hexaluminate composite layer provided by the invention are matched, so that the composite layer has the advantages of high temperature resistance and corrosion resistance, meanwhile, the calcium hexaluminate composite layer is equivalent to the matrix layer in thermal performance and is well matched with the matrix layer, the composite layer is not easy to separate and fall off, and the service life of the sagger is prolonged. The method has the advantages of low production cost, simple process, energy conservation and environmental protection.

Owner:湖南荣晟昌新材料科技有限公司

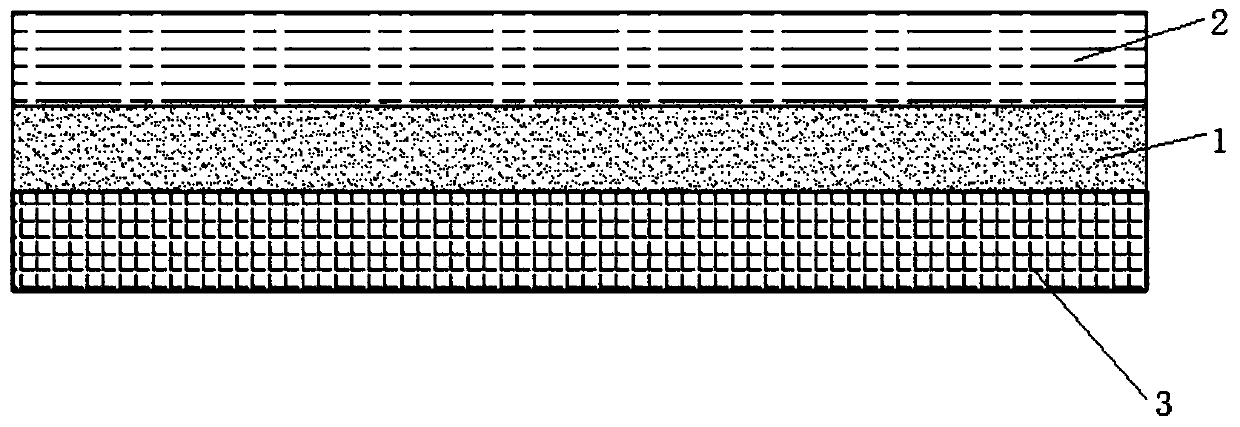

Plastic plate and molding equipment

InactiveCN106273311AImprove efficiencyLow costSynthetic resin layered productsLaminationPolymer adhesivePolystyrene

The invention discloses plastic plate molding equipment. The equipment comprises a first plastic extruding machine, a second plastic extruding machine, a third plastic extruding machine, first guide rollers, an upper-layer nonwoven fabric layer unwinding equipment first unwinding device, a lower-layer nonwoven fabric layer unwinding equipment second unwinding device, second guide rollers and traction devices which are arranged sequentially, wherein the first plastic extruding machine is used for extruding a middle-layer heat-insulation plate; the second plastic extruding machine is used for extruding an upper plastic sheet layer; the third plastic extruding machine is used for extruding a lower plastic sheet layer; a setting mold is fixedly connected onto a first setting device; a heat-insulation plate machine head is mounted on the first plastic extruding machine, an extruded heat-insulation plate blank is cooled and set by the setting mold of the first setting device, and a continuous heat-insulation plate is formed; the middle-layer heat-insulation plate, the modified plastic sheet layer on the upper side, the modified plastic sheet layer on the lower side and grid fabric or nonwoven fabric are bonded together in a hot-melt manner respectively; the heat-insulation plate is made of polystyrene (PS), polyvinyl chloride (PVC), polyurethane (PU), polypropylene (PP), polyethylene (PE) and ethylene-vinyl acetate (EVA); and the plastic sheet layers are made of PVC, PP, PE and PU. The grid fabric or the nonwoven fabric or a polymer adhesive layer has the good bonding property to a wall and does not fall off easily, and the service life is long.

Owner:DALIAN HUAGONG INNOVATION TECH

Polypeptide single-layer film with primary amino exposure amount of 6%, and preparation method and application for polypeptide monolayer film

ActiveCN111671971ARelease stabilityPrevention early intervention treatmentTissue regenerationCoatingsWhole bodyBiology

The invention provides a polypeptide single-layer film with a primary amino exposure amount of 6%, and a preparation method and an application for the polypeptide single-layer film. The polypeptide iscomposed of polypeptide molecules with a molecular weight of (1.48 + / - 0.2) * 10<5> g / mol; the thickness of the single-layer film is 14.6 + / - 0.1 nm; the exposure amount of primary amino groups on the surface of the film is 6 + / - 0.3%; the Zeta potential of the polypeptide single-layer film is minus 4.48 + / - 0.1 mV; and the contact angle of the film is 45 + / - 1 degrees. The polypeptide single-layer film provided by the invention has good stability; the exposure amount of primary amino groups on the surface of the film is accurately controlled to be 6.0 + / - 0.3%; and the polypeptide single-layer film can be applied to an oral implant surface coating material, and can carry antibiotics and antibacterial drugs and stably release the antibiotics and the antibacterial drugs; and the local drug-loaded coating of the polypeptide single-layer film has the advantages of small toxic and side effects on the whole body, strong antibacterial property and the like, is uniformly and tightly combinedwith a pure titanium material, and is not prone to separating and falling off.

Owner:QILU UNIV OF TECH

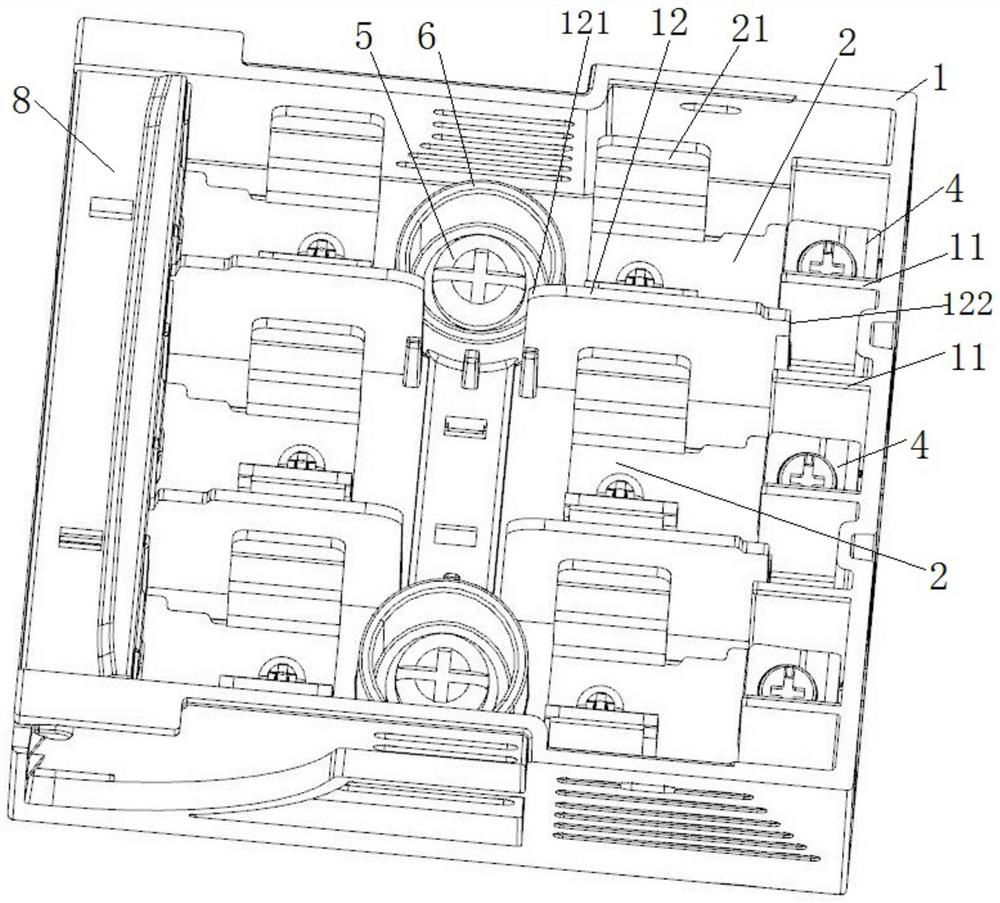

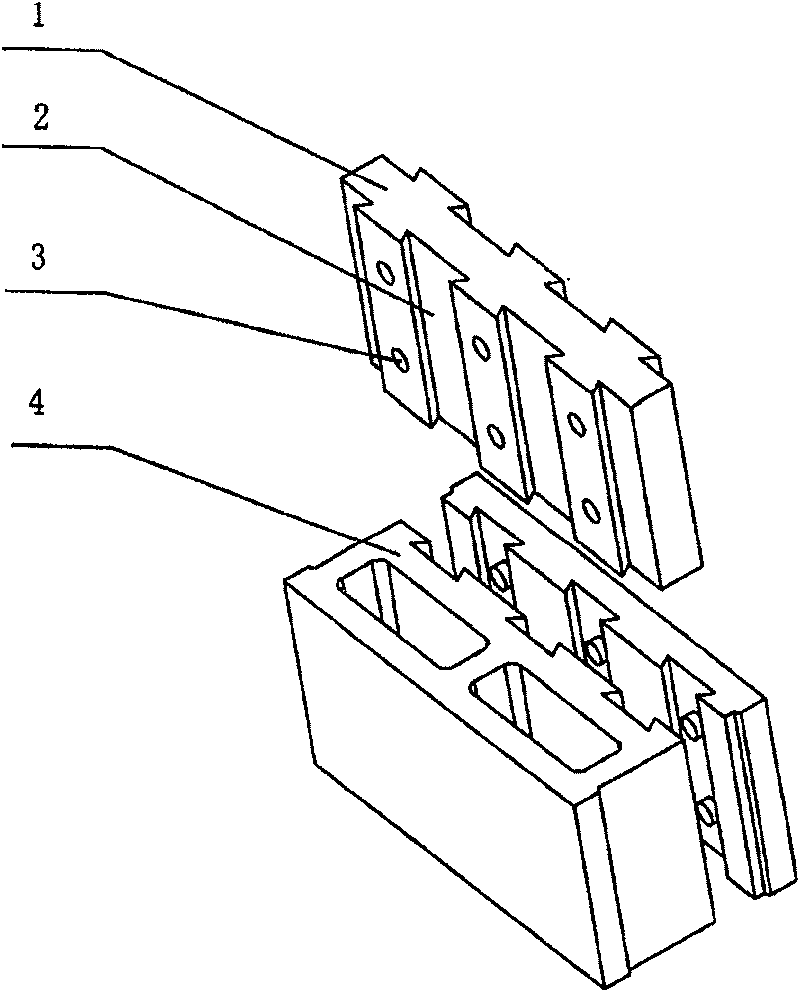

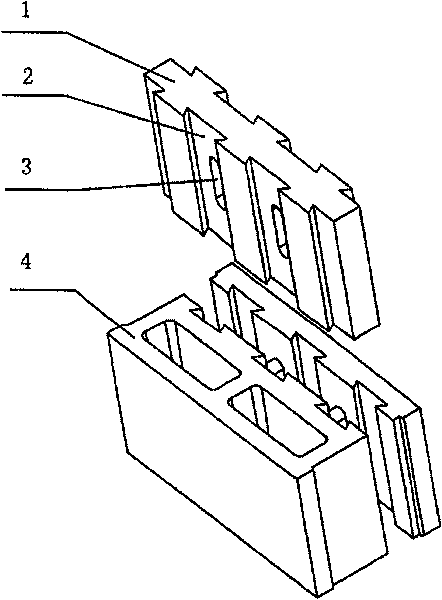

Miniature fuse type isolating switch

PendingCN111933467AIncrease creepage distanceIncrease electrical clearanceElectric switchesEmergency protective devicesEngineeringStructural engineering

The invention provides a miniature fuse type isolating switch, which comprises a plurality of contacts arranged on a base, an elastic contact part capable of being clamped with a fusible core being arranged at one end of each contact, the other end of each contact being connected with a wiring terminal, and a first partition plate being arranged between every two adjacent wiring terminals; and a second partition plate, arranged between the two adjacent contacts, the left end surface of the second partition plate exceeding the elastic contact part, and the right end surface of the second partition plate extending into an inner cavity formed by the two adjacent first partition plates. By lengthening the end faces of the two sides of the second partition plate, the creepage distance and the electrical gap between every two adjacent contacts are increased, then the rated stamping withstand voltage and the rated insulation voltage of the product are improved, and the use requirements of customers in some special occasions are met.

Owner:浙江金莱勒电气有限公司

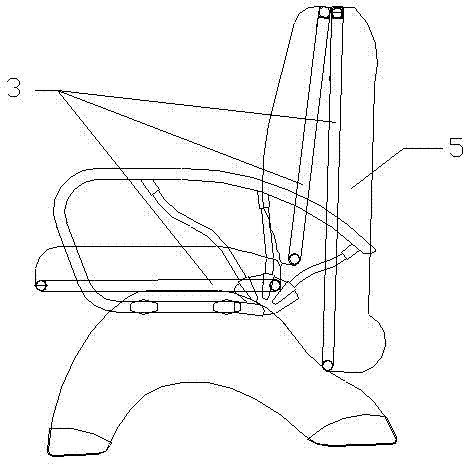

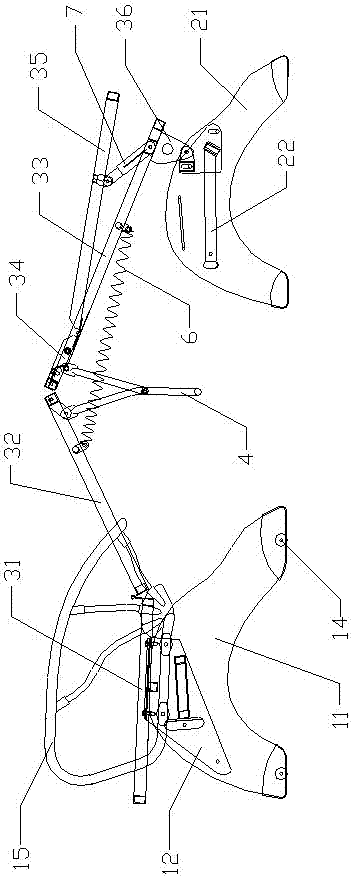

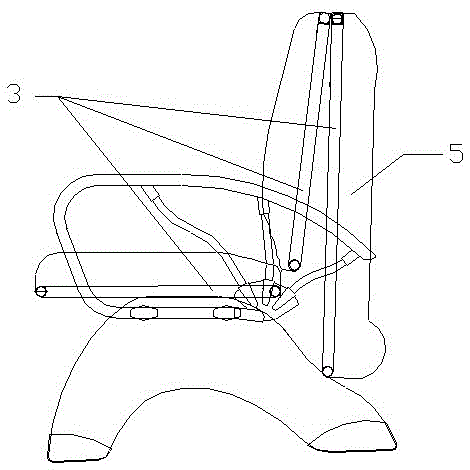

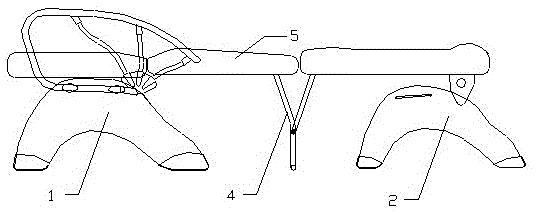

Siesta chair

ActiveCN102813399ASymmetrical positioning is accurate and convenientEasy to stretchBenchesConvertible chairsEngineeringMechanical engineering

Owner:江阴市凯丽康健器材有限公司

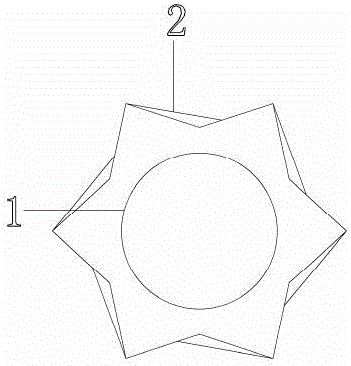

Cigarette firmware material meeting safety requirements and application thereof

ActiveCN106263022ASolve problems that affect the aroma of smokeImprove aestheticsTobacco smoke filtersFood safetyTar

The invention provides a cigarette firmware material meeting safety requirements and an application thereof, and relates to the technical field of cigarette firmware materials. An existing filtering rod purely depends on the improved draw resistance and the improved filtering efficiency to achieve the effects of reducing tar and lessening harm, or for keeping the smoke fragrance, the adsorption efficiency of the filtering rod is reduced; the cigarette firmware material meets food-safety raw material preparing, and has unique cross-grain spiral guiding groove; after the cigarette firmware material is combined with a common filtering rod, damage of the existing high-draw-resistance and high-filtering filtering rod to smoke fragrance can be eliminated, the effects of reducing tar and lessening harm of the filtering rod are not reduced, and the cigarette safety requirements are met.

Owner:ENDIAN SCI & TECH DEV OF YUNNAN

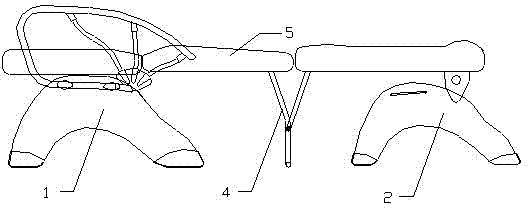

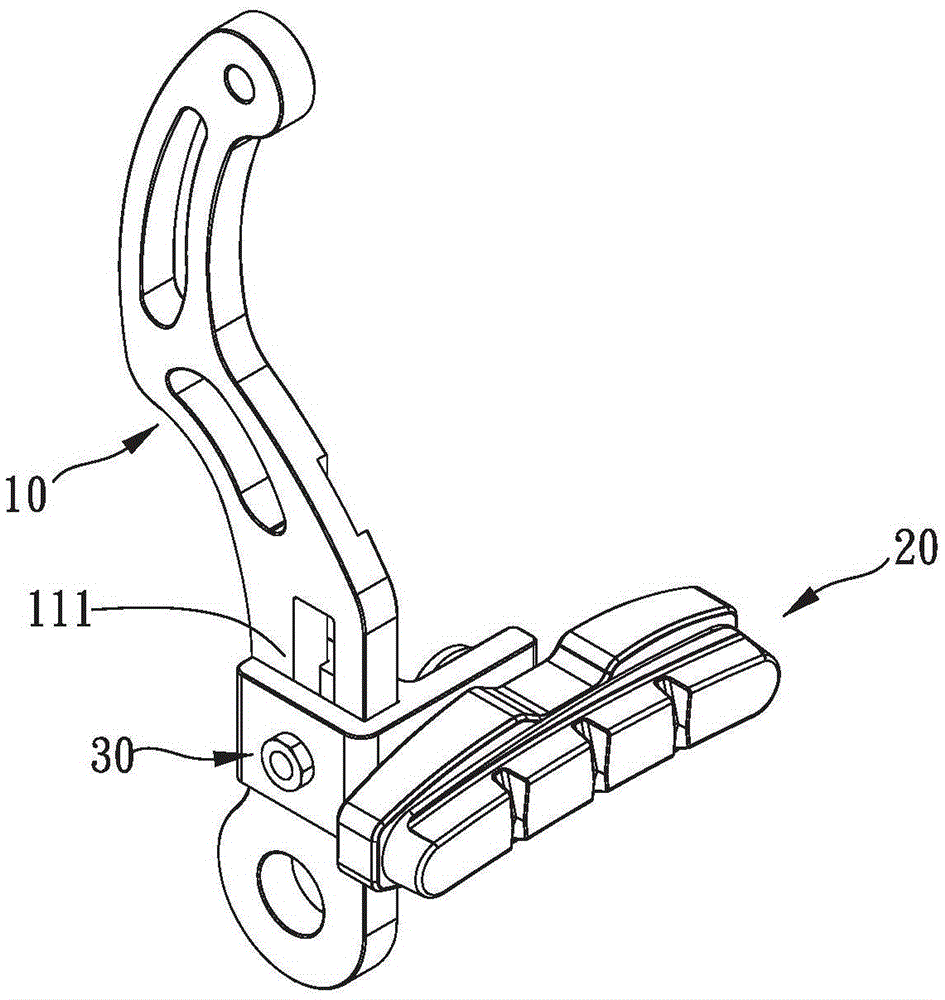

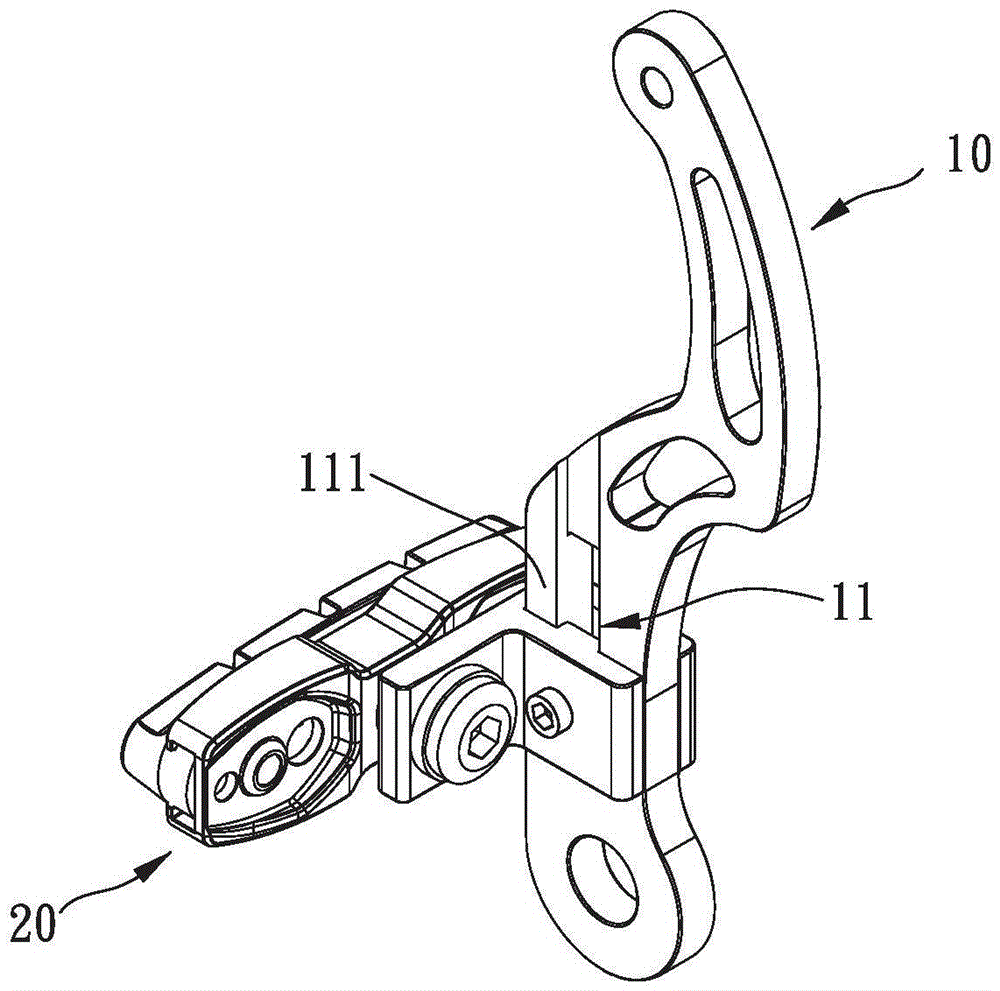

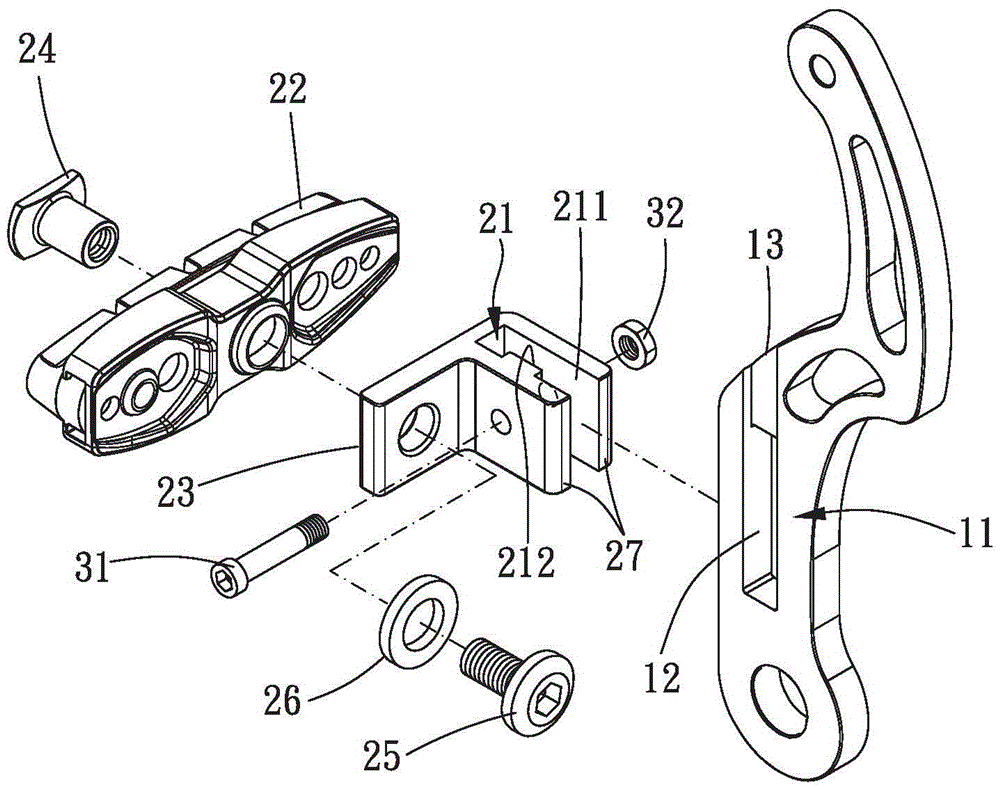

Brake system and V clamp brake

The invention relates to a V clamp brake which is used for being assembled on a bicycle, wherein the bicycle comprises two fork rods and a wheel set assembled between the two fork rods. The V clamp brake comprises two brake swing arms and two brake block components, wherein the two brake swing arms are respectively assembled on the two fork rods in a mode of pivoting to the wheel set, and each brake swing arm is provided with a connection part; and the two brake block components are respectively assembled on the two brake swing arms, and each brake block component is concavely provided with an assembling slot which is positioned at the connection part in a sliding mode. The invention also provides a brake system which comprises the V clamp brake and a wire component, wherein the wire component is used for connecting the two brake swing arms, and the wire component can be operated to drive the two brake swing arms and the two brake block components to swing towards the wheel set.

Owner:温芫鋐

Ceramic and rock wool integrated board

PendingCN110397233AHigh strengthNot easy to separate and fall offCovering/liningsConstructions elementsGlass fiberUltimate tensile strength

The invention discloses a ceramic and rock wool integrated board. The ceramic and rock wool integrated board comprises a rock wool layer. The two sides of the rock wool layer are provided with a ceramic board and a glass fiber reinforced cement-based felt correspondingly. Adhesion glue layers are arranged between the ceramic board and the rock wool layer and between the rock wool layer and the glass fiber reinforced cement-based felt. According to the ceramic and rock wool integrated board, the ceramic board and the rock wool layer are connected in a concave-convex fit manner, so that the connection strength is improved, and separation and disengagement are not prone to happen. The ceramic board is used as a facade of building wall and is attractive and durable; and meanwhile, the ceramicboard and the rock wool layer adhere to each other in advance, so that construction is more convenient. The glass fiber reinforced cement-based felt adheres to the rock wool layer, the adhesion strength between the glass fiber reinforced cement-based felt and cement on the outer wall is higher, and therefore the safety is improved.

Owner:湖北卓宝建筑节能科技有限公司

a tire

The invention relates to the technical field of tires, in particular to a novel tire. The novel tire comprises a tire body, a rim, spokes and an axle, wherein the rim and the spokes are integrally formed; the spokes are connected with the rim and the axle; the rim consists of a left rim and a right rim; the shape of the left rim is the same with that of the right rim; the left rim and the right rim are symmetrically arranged in the left-right direction; annular stopping portions are formed on the left side surface and the right side surface of the rim; a left half clamping portion is formed at the peripheral edge of the left rim; a right half clamping portion is formed at the peripheral edge of the right rim; the left half clamping portion and the right half clamping portion are welded together to form a clamping portion; and the tire body is sleeved on the clamping portion. Materials of the tire can be saved by 20%, and the replacement cost is saved. Compared with the existing foaming tire used for slowly-running load-bearing vehicles such as a hand trolley and a cart, the novel tire has the advantages that the service life is long, the tire body is not easily separated from the rim, and the novel tire is used safely and is high in load- bearing force; and the bearing strength of the novel tire is twice to three times greater than that of the common foaming tire, the continuous working time of the novel tire is three times to four times longer than that of the common foaming tire, and a load-bearing vehicle with the novel tire can be easily pushed.

Owner:青岛力王工具有限公司

A painless suction medical needle and its production process

ActiveCN105195984BNo damage deformationPain reliefSurgerySuction devicesAtmospheric pressureSyringe needle

The invention discloses a painless suction type medical needle and a production technology thereof. A smooth and arc-shaped needle head is welded at the front end of the suction type medical needle with a welding technology, so that the needle head in the body cannot cause inevitable secondary injuries due to puncture of a patient, and the pain of the patient can be greatly relieved when the smooth and arc-shaped needle head is located in the body; the needle head is round and safer than a sharp-head needle, an opening is formed in the side surface, an injection medium is more uniform, the injection effect is better, and through cooperation of TIG (tungsten inert gas) welding with subsequent hydraulic and pneumatic purging grinding, the needle head welded on a tiny needle tube is firm and smooth. The TIG welding technology is adopted, a workpiece is molten, a specific molten pool is formed, the tiny needle head and needle tube can be well combined and cannot separate and fall easily, the needle tube cannot be damaged and deformed during welding, a black film formed by chemically corroded scale marks is firm, the processing temperature is low, and accordingly, the attractive appearance can be kept.

Owner:桐城市建设投资发展有限责任公司

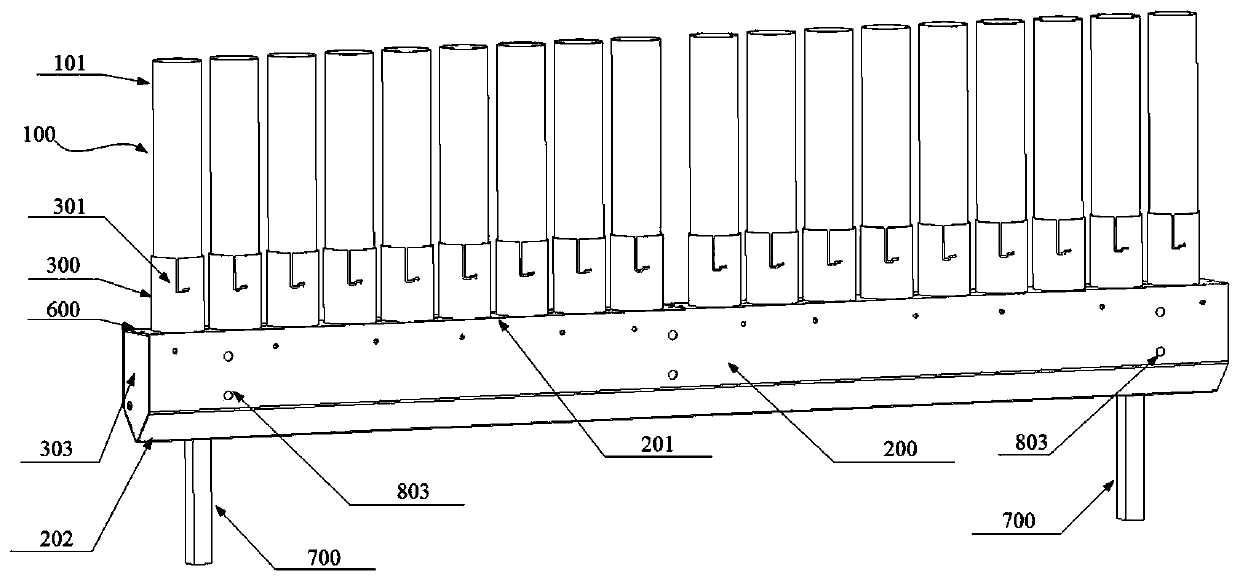

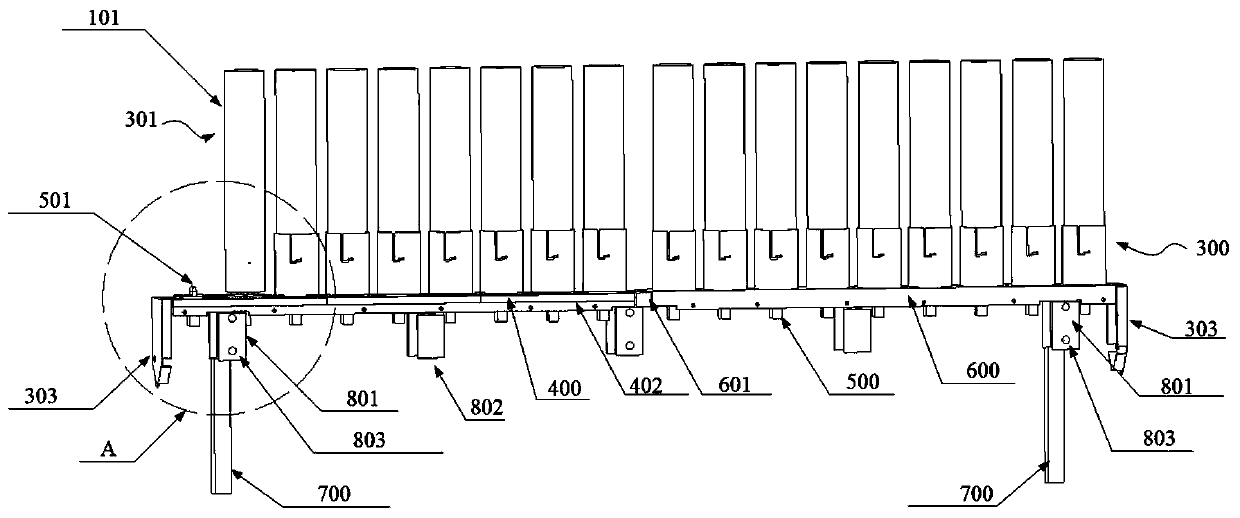

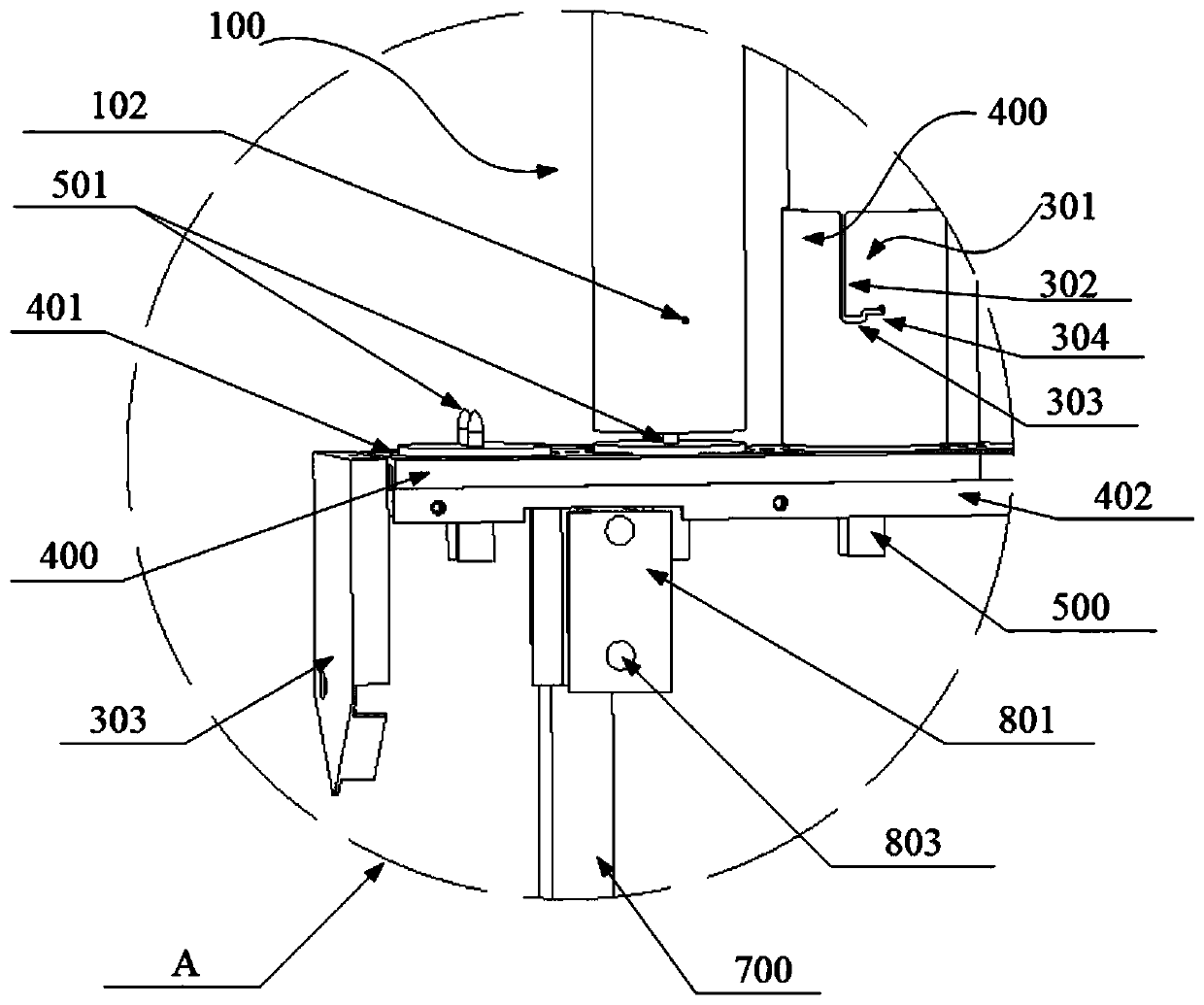

Special synchronous core-building apparatus for processing concrete building block with vertical thermal insulation core layer

InactiveCN101387149BNot easy to separate and fall offImprove bindingConstruction materialCeramic shaping apparatusThermal insulationEngineering

The invention discloses a heat preservation concrete block and a special synchronous core filling machine thereof. The invention relates to a heat preservation concrete block and a core filling devicefor processing the same. Surfaces of two sides of a heat preservation core layer or a bottom surface of a dovetail groove are provided with concave pits, respectively; and the heat preservation layerare connected with concrete layers at two sides through the dovetail groove and the concave pits. The synchronous core filling device is arranged at the rear part of a vibrating table of a block forming machine and consists of a machine frame, guide rails, a trolley, a driving device of the trolley, and a carrier, a supporting plate, rails of the supporting plate, a controller and a trolley position sensor which are fixedly connected on the trolley, wherein the rails of the supporting plate is as high as or higher than the vibrating table of the block forming machine, the supporting plate isplaced on the rails of the supporting plate. The carrier is arranged on the upper part of the front end of the trolley, and a pushing device for the supporting device is arranged on the lower part ofthe front end of the trolley. The trolley position sensor and the driving device of the trolley are connected with the controller. The heat preservation concrete block is bonded firmly and has the advantages of good heat preservation effect, high strength, low processing cost and high processing efficiency.

Owner:扬州威奥重工机械有限公司

Airborne smoke bar spreading device

PendingCN110015423AReduce local stressReduce wind resistanceAircraft componentsWeather influencing devicesEngineeringGravitation

The invention relates to an airborne smoke bar spreading device. The airborne smoke bar spreading device comprises a plurality of smoke bars and a spreading shell body; the multiple smoke bars are installed on the spreading shell body, and the multiple smoke bars are parallel to each other and are arranged and distributed into a linear row in a spaced mode; due to the fact that the multiple smokebars fixed to the spreading shell body are parallel to each other and arranged and distributed into the linear row in a spaced mode, so that the structure can effectively reduce wind drag, and the structure can be applied to a high-speed airplane; in addition, structurally, the airborne smoke bar spreading device can be divided into a plurality of similar areas, the areas enable the gravity of theairborne smoke bar spreading device be in a dispersed distributed state, namely, the gravity of the airborne smoke bar spreading device of the structure is not concentrated on a certain point or in several limited areas, so that the local stress of an installing position on the airplane is greatly reduced, and damage is reduced; and furthermore, smoke bars of various specifications and differentfunctions can be adopted, and the general applicability of the airborne smoke bar spreading device can be further enhanced.

Owner:CHINESE ACAD OF METEOROLOGICAL SCI +1

Method for producing rust-proof uvioresistant black iron oxide

InactiveCN103333541BNot easy to separate and fall offAnti-rustCoatingsPigment treatment with non-polymer organic compoundsUltraviolet lightsSlurry

The invention discloses a method for producing rust-proof uvioresistant black iron oxide. The method comprises the following steps of preparing the black iron oxide through a sodium hydroxide oxidation method, adding aluminium triphosphate of about 3-6% of the weight of a black iron oxide filter cake, 0.2-0.3% of ultraviolet light absorber UV-327, 0.4-0.5% of di-(dioctyl oxygen pyrophosphate) ethylene metatitanic acid and 0.5-1% of deionized water, grinding at a high speed for 10-20 minutes by 2500-3000rpm, after taking out and drying, adding moderate water for pulping for 20-30 minutes, and preparing serous fluid with concentration of 55-65%. According to the method, the aluminium triphosphate, the ultraviolet light absorber UV-327, the di-(dioctyl oxygen pyrophosphate) ethylene metatitanic acid and the deionized water are firstly added for grinding, the aluminium triphosphate and the ultraviolet light absorber are bridged through the titanate so as to be coated on the surface of the black iron oxide, thus being not easy to be separated and fall off and forming a layer of rust-roof film on the surface of the black iron oxide, therefore, the black iron oxide has a rust-proof function and improves the anti-ultraviolet performance.

Owner:ANHUI TOPTECHSCR ENVIRONMENTAL SCI & TECH

Lunch chair

ActiveCN102813399BSymmetrical positioning is accurate and convenientEasy to stretchBenchesConvertible chairsEngineeringMechanical engineering

Owner:江阴市凯丽康健器材有限公司

Polypeptide monolayer film with primary amino group exposure of 7%, its preparation method and application

ActiveCN111671970BImprove stabilityGood adhesionTissue regenerationCoatingsZeta potentialMembrane surface

The invention provides a polypeptide monolayer film with a primary amino group exposure of 7%, its preparation method and application. The polypeptide is composed of molecular weight (1.48 ± 0.2) × 10 5 g / mol of polypeptide molecules, the thickness of the monolayer film is 8.9 ± 0.1nm, the exposure of primary amino groups on the surface of the film is 7.0 ± 0.2%, and the Zeta potential of the polypeptide monolayer film is 0.76 ± 0.1mV; The contact angle is 48±1°. The polypeptide monolayer film of the present invention has good stability, and the exposure amount of the primary amino group on the film surface is precisely controlled at 7.0 ± 0.2%, which can be applied to oral implant surface coating materials, can carry antibiotics and antibacterial drugs and is stable Release, the local drug-loaded coating of the polypeptide monolayer film has the advantages of low systemic side effects and strong antibacterial properties. It is evenly combined with pure titanium materials and is not easy to separate and fall off.

Owner:QILU UNIV OF TECH

An assembly method of shield structure under ultra-low height

ActiveCN105960156BGuaranteed assembly qualitySimple designScreening metallic containersMode-lockingTweezers

The present invention discloses an assembly mode of a shield case structure in an ultra low height, belonging to the technical field of shield structures. According to the assembly mode, product superposition small bending mode locking assembly is used, the limit that a conventional convex hull and hole for a shield case can not be processed in an ultra low height is broken, the two-way bending of the shield case is completed in a mold, finally the angle bending of an external cover is buckled at the superposition part of an internal cover, reverse buckling is formed to complete assembly combination, and thus the defect of no processing in the traditional mode is avoided. Since the mutual buckling mode of the shield case is bending and connection, in a condition of shield case repair, the shield case can be conveniently lifted by using tweezers to gently the shield case outward. The assembly mode has the advantages of simple structure and high practicability, a defect that the external cover of a shield case product is difficult to separate after assembly and is easy to be loose after recombination in a traditional mode can be solved, and the assembly quality of the shield case can be greatly improved and ensured.

Owner:AQ HOLMBERGS SUZHOU LTD CHINA

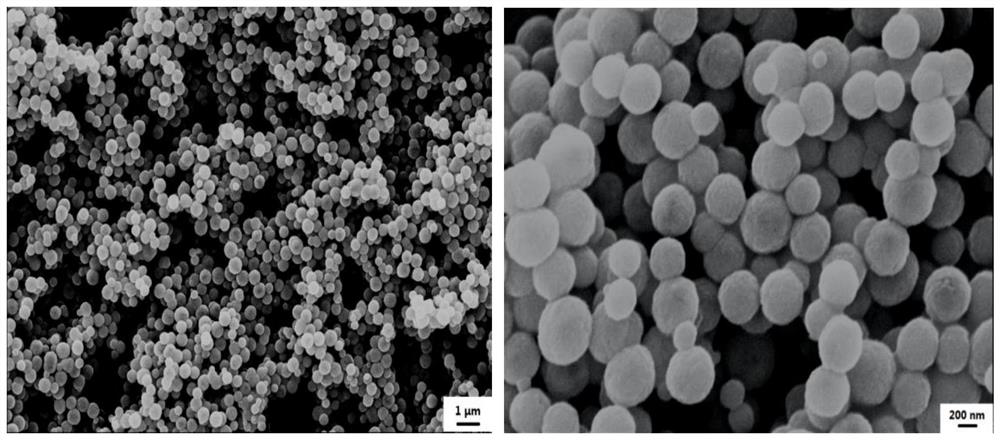

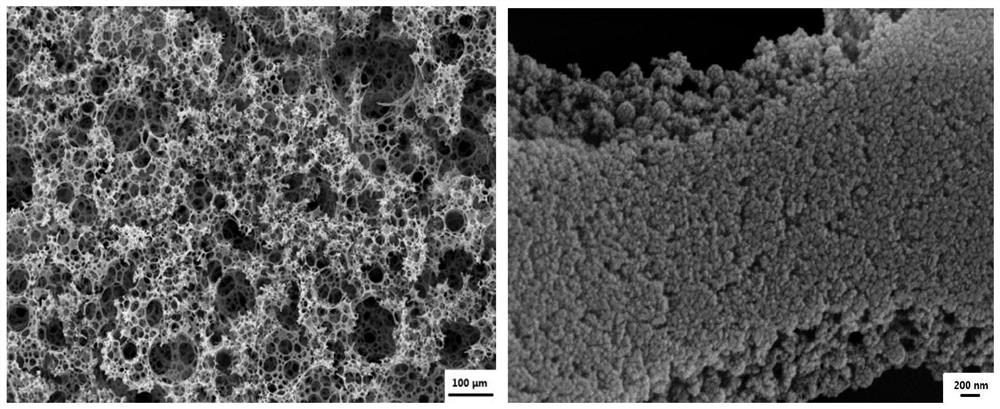

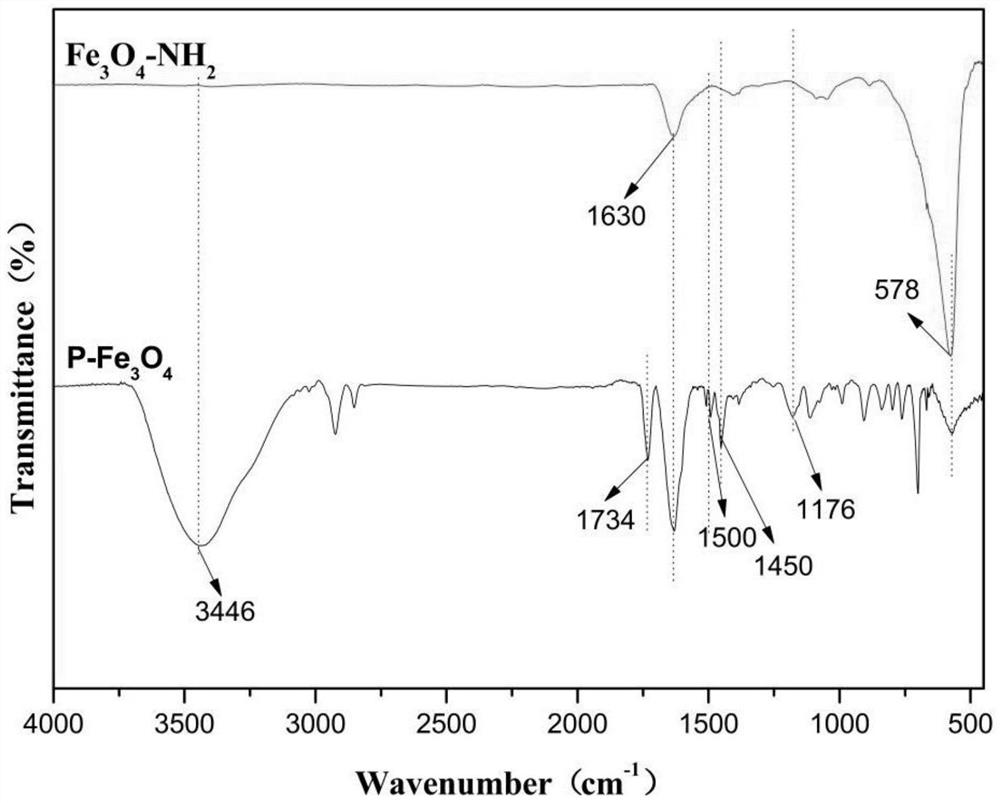

A kind of magnetic superhydrophobic polystyrene-based porous material and preparation method thereof

ActiveCN110724221BIncrease roughnessImprove bindingOrganic/organic-metallic materials magnetismChemical industryPolymer science

The invention discloses a method for preparing a magnetic superhydrophobic polystyrene-based porous material, which comprises raw materials such as styrene monomer, epoxy group-containing vinyl monomer, amino-modified iron tetraoxide and crosslinking agent, in the initiator Under the action of , water and emulsifier, polymerize at 40-80°C for 4-24h to obtain a magnetic superhydrophobic polystyrene-based porous material. The crosslinking agent is one of ethylene glycol dimethacrylate, divinylbenzene, triallyl isocyanurate, pentaerythritol triacrylate, and trimethylolpropane triacrylate. The epoxy-containing ethylenic monomer is one of glycidyl methacrylate, glycidyl acrylate, and glycidyl stearate. The magnetic superhydrophobic polystyrene-based porous material prepared by the invention has both superhydrophobicity and magnetic response, can be used for oil-water separation in the food industry, chemical industry and petroleum industry, and can perform automatic oil-water separation under magnetic drive.

Owner:SOUTHWEST PETROLEUM UNIV

Gel-poly(lactide-co-glycolide) (PLGA) two-phase gradient transition cartilage-bone repair material and preparation thereof

InactiveCN103656745BGood biocompatibilityPromote degradationBone implantGlycidyl methacrylateLactide

The invention discloses a gel-poly(lactide-co-glycolide) (PLGA) two-phase gradient transition cartilage-bone repair material and preparation thereof. The material is cylindrical and consists of an upper material and a lower material, wherein the upper material is glycidyl methacrylate-modified carboxymethyl chitosan and gelatin; the lower material is porous PLGA. The preparation process comprises the following steps: preparing a gelatin microsphere serving as a pore-forming agent into a PLGA porous scaffold of which one end face is a conical concave surface; preparing a gel solution by using the modified chitosan and modified gelatin; dripping the gel solution on the PLGA porous scaffold of the conical concave surface, inverting, performing ultraviolet light cross-linking to obtain the gel-PLGA two-phase gradient transition cartilage-bone repair material. The material has high biocompatibility and biodegradability, is in a two-phase gradient transition structure, is tightly combined without drop and is simple in preparation process.

Owner:TIANJIN UNIV

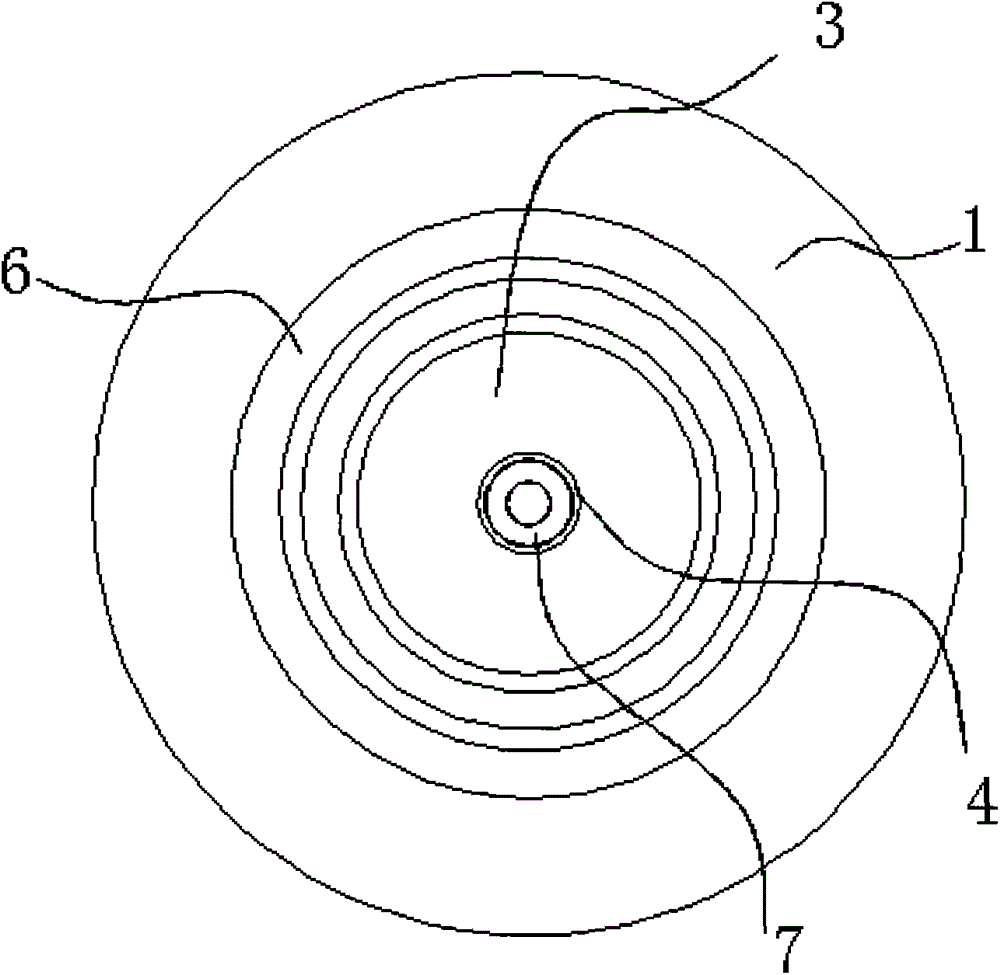

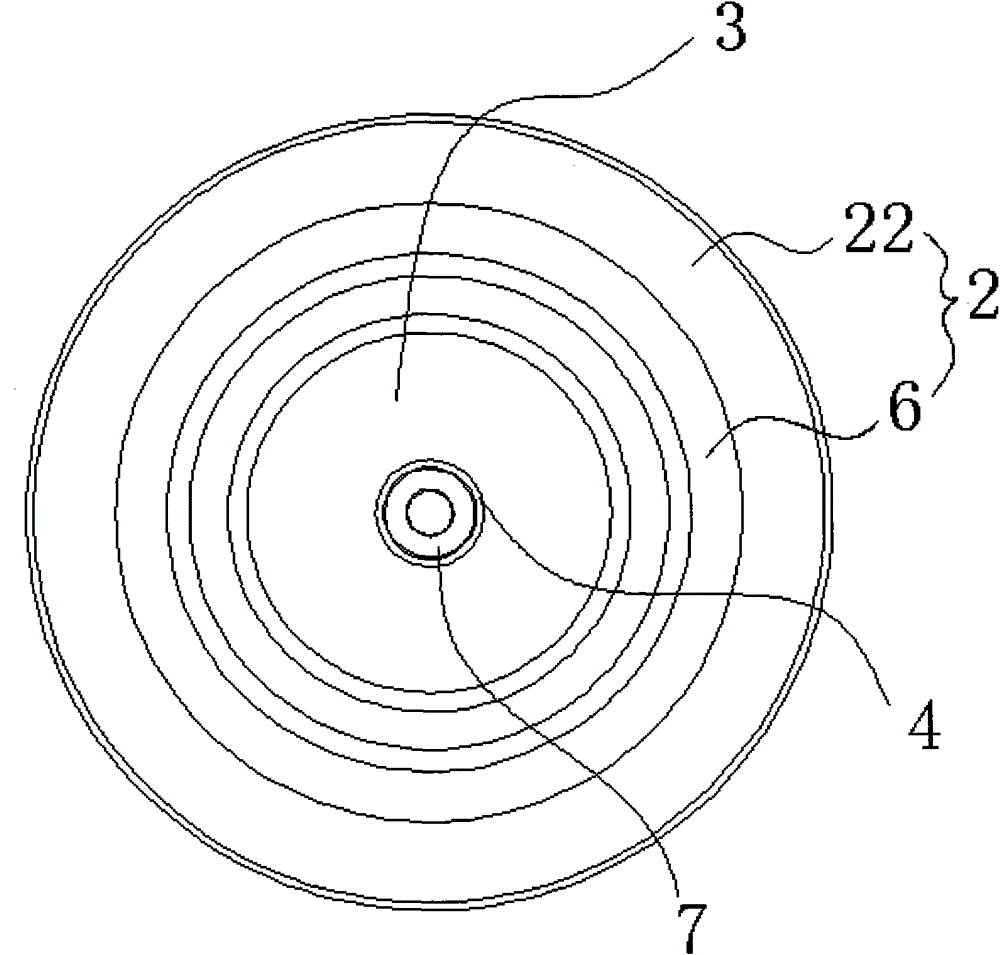

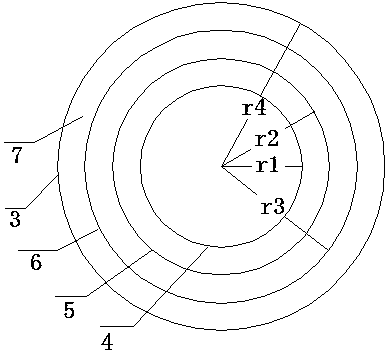

Grinding wheel for high-speed railway

InactiveCN104162846AExtended service lifeIncrease bite depthBonded abrasive wheelsEngineeringGrinding wheel

The invention relates to a grinding wheel for a high-speed railway. The grinding wheel comprises a grinding wheel basic body and a grinding wheel main body. The grinding wheel main body is fixed to the position above the grinding wheel basic body, the grinding wheel basic body comprises a base, the base is sequentially provided with a first baffle, a second baffle, a third baffle and a fourth baffle from inside to outside in the circumferential direction, a circle of convex strips are arranged on the outer side of the first baffle in the circumferential direction, the outer side of the second baffle and the inner side of the second baffle are respectively provided with a circle of convex strips in the circumferential direction, the outer side of the third baffle and the inner side of the third baffle are respectively provided with a circle of convex strips in the circumferential direction, and the inner side of the fourth baffle is provided with a circle of convex strips in the circumferential direction. Thus, the grinding wheel basic body and the grinding wheel main body can be firmly fixed to form a whole and are not prone to falling off, the service life is prolonged, and use safety is guaranteed.

Owner:镇江丰成特种工具有限公司

A kind of preparation method of bamboo fiber molding composite material

ActiveCN111516073BEfficient use ofIncrease the gapRadiation/waves wood treatmentPressure wood treatmentFiberCeramic materials

Owner:ZHEJIANG FORESTRY ACAD

Ceramic and preparation method thereof,

InactiveCN103568407AImprove adhesionImprove bindingNon-macromolecular adhesive additivesCeramic layered productsEpoxyLacquer

The invention provides ceramic and a preparation method thereof. The ceramic is composed of a ceramic substrate layer, an intermediate adhesion paint layer and a UV (ultraviolet) material layer, wherein the intermediate adhesion paint layer is used as an intermediate layer to mutually combine the ceramic substrate layer with the UV material layer; the intermediate adhesion paint layer is composed of modified epoxy resin, a curing agent and a diluent, the content proportion of the modified epoxy resin, the curing agent and the diluent is 7:1:3.5, and the ceramic is mainly prepared layer by layer through spray-up molding and roller painting. According to the ceramic provided by the invention, the ceramic substrate and the UV material are firmly adhered and combined, thereby being waterproof and unlikely to separate or drop.

Owner:曹柏林

A double-layer functional food packaging bag

The invention discloses a double-layer functional form food packaging bag and belongs to the field of food packaging. The double-layer functional form food packaging bag comprises a packaging bag bodyof which the upper end is fixedly connected with a packaging bag head through a sealing strip; the packaging bag body comprises an outer packaging bag layer and an inner packaging bag layer; the sealing strip comprises a sealing concave strip and a sealing convex strip; a closed auxiliary drying mechanism is arranged in the position of the sealing concave strip; the lower end of the closed auxiliary drying mechanism is connected with a double-layer drying structure; a plurality of cavities are arranged inside the sealing concave strip; an auxiliary drying combined ball is placed inside the cavity; another closed auxiliary drying mechanism is arranged at the sealing part of the packaging bag body, a double layer drying structure is also arranged in the position of the closed auxiliary drying mechanism, the closing state of the closed auxiliary drying mechanism can be kept under a state that the bag body is opened, so as to keep the stable drying performance of the auxiliary drying combined ball inside the cavity. Therefore, during the food packaging bag re-sealing process, a complete drying effect is played, and the drying effect lasts for long.

Owner:浙江中塑包装印务有限公司

Polypeptide monolayer film with 6% primary amino group exposure and its preparation method and application

ActiveCN111671971BImprove stabilityGood adhesionTissue regenerationCoatingsPolymer chemistryAntibacterial property

The invention provides a polypeptide monolayer film with a primary amino group exposure of 6%, as well as its preparation method and application. The polypeptide is composed of molecular weight (1.48 ± 0.2) × 10 5 g / mol of polypeptide molecules, the thickness of the monolayer film is 14.6±0.1nm, the exposure of primary amino groups on the surface of the film is 6±0.3%, and the Zeta potential of the polypeptide monolayer film is -4.48±0.1mV; the film The contact angle is 45±1°. The polypeptide monolayer film of the present invention has good stability, and the exposure amount of the primary amino group on the film surface is precisely controlled at 6.0 ± 0.3%, which can be applied to oral implant surface coating materials, can carry antibiotics and antibacterial drugs and is stable Release, the local drug-loaded coating of the polypeptide monolayer film has the advantages of low systemic side effects and strong antibacterial properties. It is evenly combined with pure titanium materials and is not easy to separate and fall off.

Owner:QILU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com