a tire

A technology for tires and rims, which is applied in the direction of wheels, rims, spoke wheels, etc. It can solve the problems of long continuous working time and large bearing capacity, and achieve the effects of long service life, large bearing capacity and saving replacement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and example the present invention will be further described:

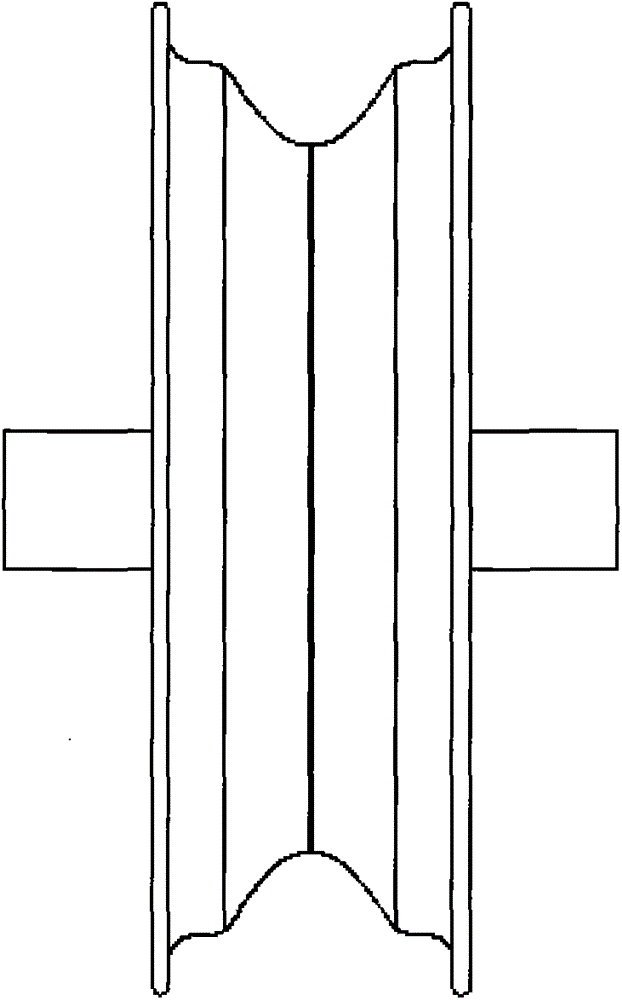

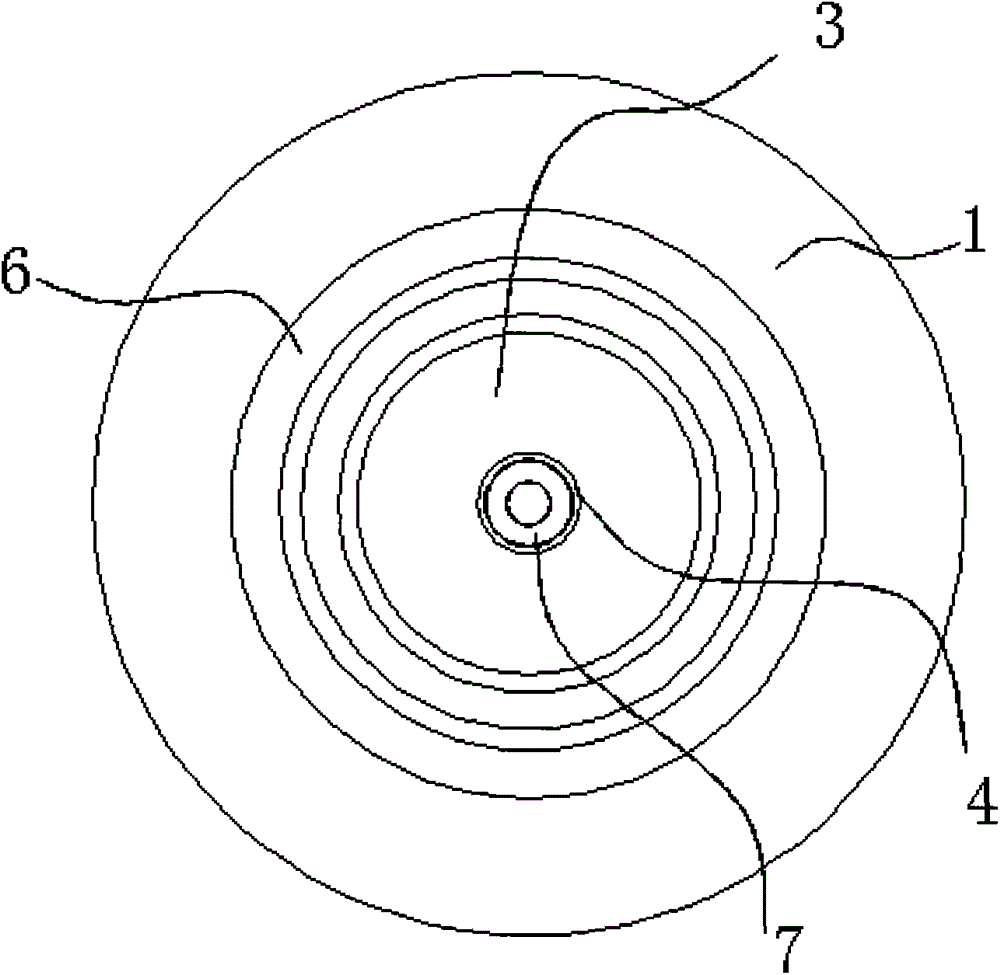

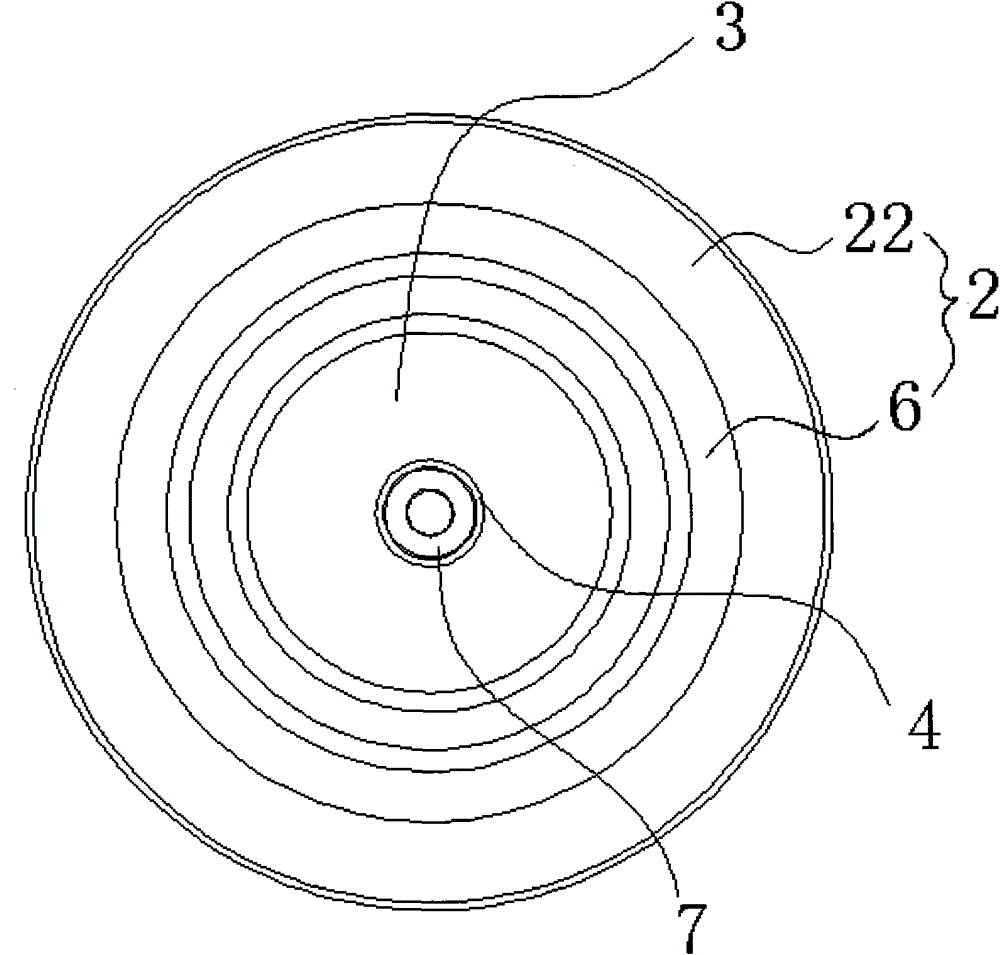

[0020] like Figure 2 to Figure 5 As shown, a kind of tire comprises: tire 1, wheel rim 2, wheel spoke 3 and wheel axle 4, and described wheel rim 2 and wheel spoke 3 are integrally formed, and described wheel spoke 3 connects wheel rim 2 and wheel axle 4, and described wheel rim 2 is formed by left wheel rim 20 Composed of the right rim 21, the left rim 20 and the right rim 21 have the same shape and are symmetrically arranged left and right. The left and right sides of the rim 2 protrude outward to form an annular stopper 6. The edge bulges toward the direction away from the axis of the wheel shaft 3 to form a left half snap-fitting portion 22, and the peripheral edge of the right rim 21 bulges toward a direction away from the axis of the wheel shaft 3 to form a right half snap-fit portion 23, and the left half snap-fits The right edge of the part 22 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com