Fiber reinforced heat insulation composite hose and manufacturing method thereof

A composite hose and fiber-reinforced technology, applied in the field of composite hoses, can solve the problem that the hose cannot have good strength and thermal insulation and cold insulation performance at the same time, and achieve the effect of excellent thermal insulation and cold insulation effect, easy process control, and not easy to separate and fall off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

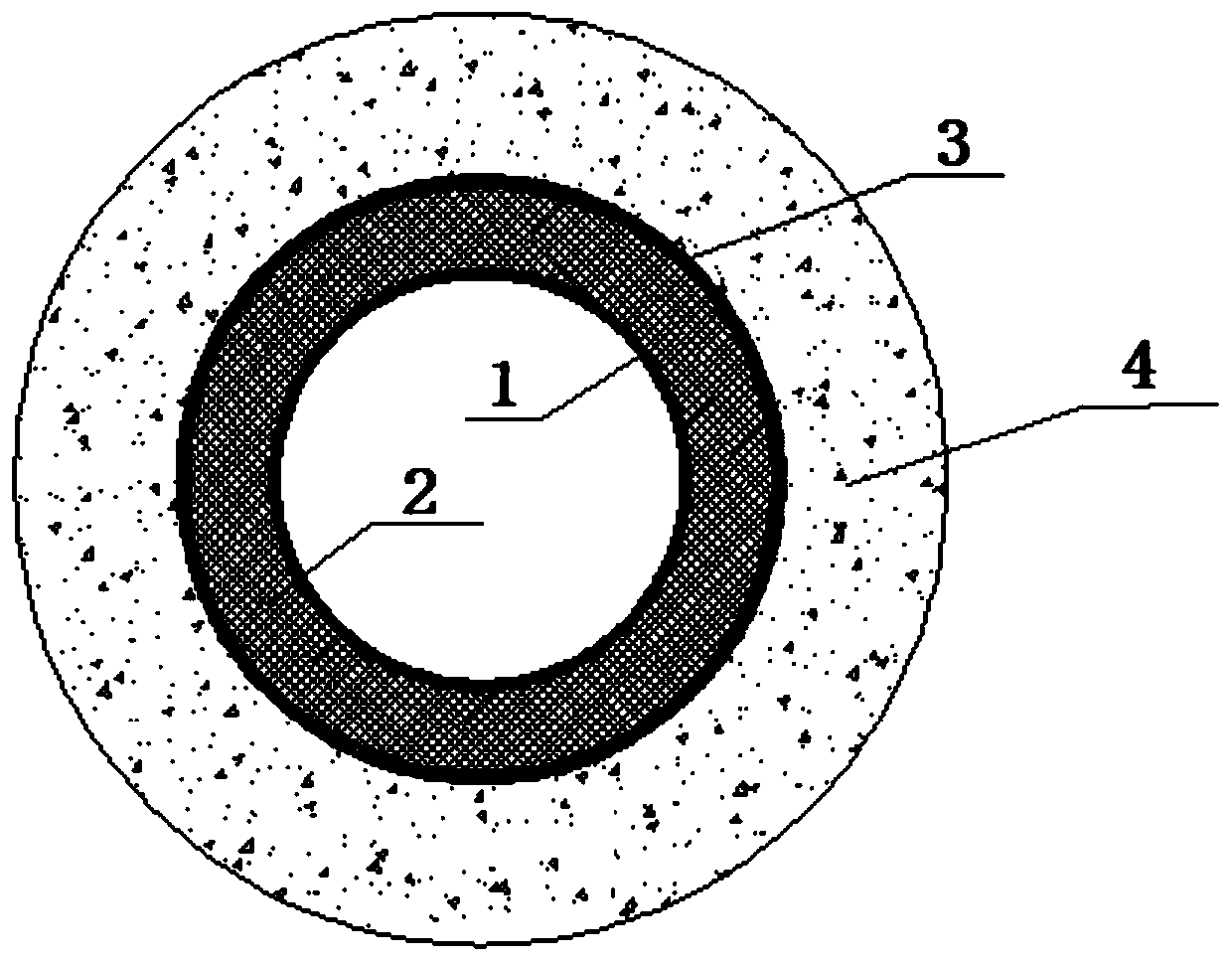

[0036] Such as figure 1 As shown, a fiber-reinforced heat-insulated composite hose includes a reinforcement layer, which is characterized in that the reinforcement layer includes an inner liner 1 and a strip blank 2 compounded on the outer surface of the inner liner 1 by hot melting, The outer surface of the blank 2 is sequentially provided with a hot melt adhesive film layer 3 and a heat insulating layer 4; the material of the heat insulating layer 4 is a microcapsule foaming material;

[0037] The material used for the inner liner 1 is a thermoplastic elastomer;

[0038] The material used for the strip blank 2 is 1000D high-strength polyester fiber, and the strip blank 2 is woven into a circular strip blank with an inner diameter of 50 mm by weaving warp and weft threads through a circular loom;

[0039] The material used for the hot melt adhesive film layer 3 is polyurethane, the thickness of the film layer is 80 μm, and the thickness of the heat insulation layer 4 is 8 mm...

Embodiment 2

[0048] Such as figure 1 As shown, a fiber-reinforced heat-insulated composite hose includes a reinforcement layer, which is characterized in that the reinforcement layer includes an inner liner 1 and a strip blank 2 compounded on the outer surface of the inner liner 1 by hot melting, The outer surface of the blank 2 is sequentially provided with a hot melt adhesive film layer 3 and a heat insulating layer 4; the material of the heat insulating layer 4 is a microcapsule foaming material;

[0049] The material used for the inner liner 1 is nitrile rubber;

[0050] The material used for the strip blank 2 is 1000D high-strength polyester fiber, and the strip blank 2 is woven into a circular strip blank with an inner diameter of 50 mm by weaving warp and weft threads through a circular loom;

[0051] The material used for the hot melt adhesive film layer 3 is polyurethane, the thickness of the film layer is 60 μm, and the thickness of the heat insulation layer 4 is 4 mm.

[0052]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com