Plastic plate and molding equipment

A technology of plastic sheet and molding equipment, applied in the direction of synthetic resin layered products, lamination, layered products, etc., can solve the problem of low bonding strength between insulation boards and wall materials, high technical level requirements, and difficult quality Guarantee and other issues, to achieve the effect of easy quality assurance, not easy to fall off, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

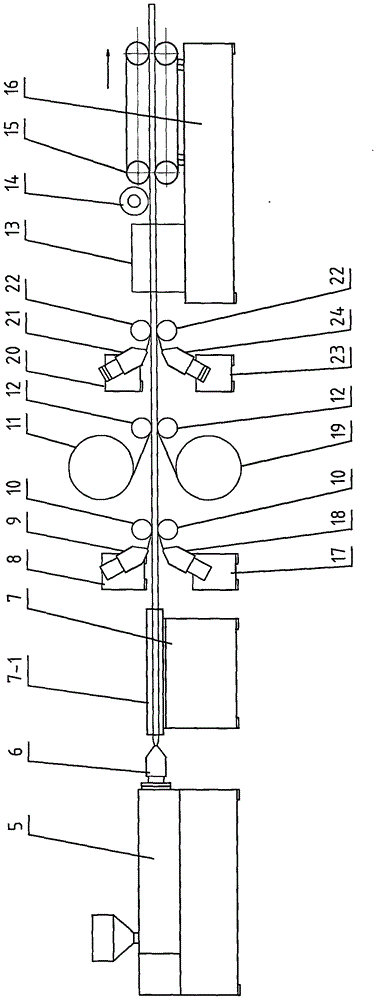

[0018] Example 1: Such as Figure 1~3 As shown, the present invention will be further explained below in conjunction with the drawings. A plastic sheet forming equipment, comprising a first plastic extruder 5 for extruding the middle layer insulation board 1 in sequence, a second plastic extruder 8 for extruding the upper plastic sheet 2 and extruding the lower plastic sheet 2, the third plastic extruder 17, the first guide roller 10, the upper non-woven fabric layer unwinding device, the first unwinding device 11, the lower non-woven fabric layer unwinding device, the second unwinding device 19, the second guide roller 12. The traction device 15, the shaping die 7-1 is fixedly connected to the first shaping device 7, which is characterized in that the heat preservation board head 6 is installed on the first plastic extruder 5, and the extruded heat preservation board 1 blank passes through The shaping mold 7-1 of the first shaping device 7 is cooled and shaped to form a conti...

Embodiment 2

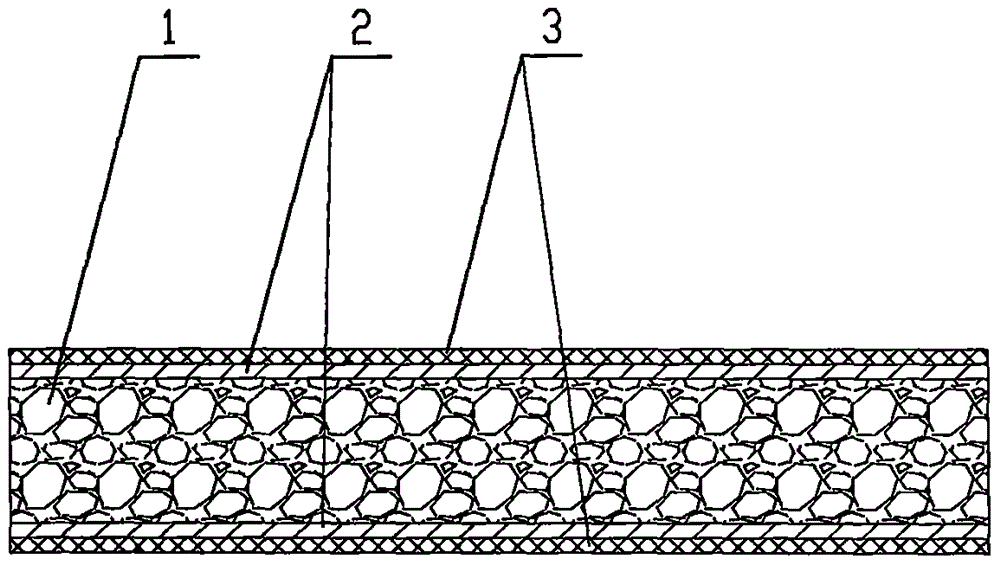

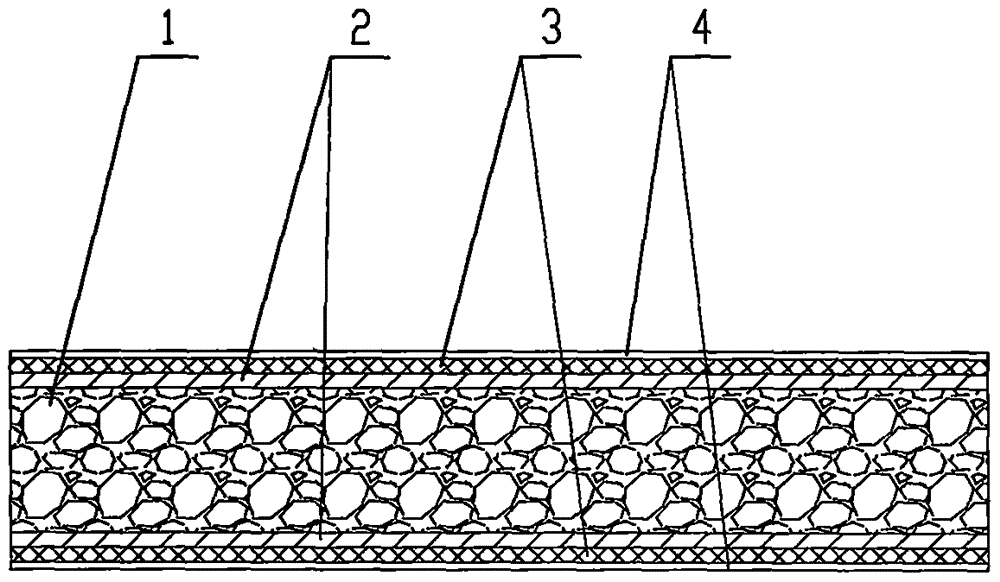

[0031] Example 2: Such as Figure 1~3 As shown, the present invention will be further explained below in conjunction with the drawings. A plastic sheet produced by a plastic sheet forming equipment according to claims 1-8, wherein the middle insulation board 1 and the modified plastic sheet layer 2 on the upper and lower sides 2, the grid cloth or the non-woven fabric 3 are respectively hot-melt bonded Together; the material of the insulation board 1 is PS, PVC, PU, PP, PE, EVA, the material of the plastic layer 2 is PVC, PP, PE, PU, and the density of the insulation board 1 of the closed cell structure is 0.03-0.3g / cm 3 ;

[0032] The plastic sheet 2 is mixed in large proportions by coupling agents, crosslinking agents, lubricants, antioxidants and fillers such as talc or calcium carbonate or kaolin or barium sulfate or porous powdered quartz or clay or fly ash, and the mixing ratio is greater than 80% Above, the increase of the above-mentioned filler is beneficial to inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com