Width-adjustable composite polycrystalline mullite fiberboard rolling device

A polycrystalline mullite, rolling device technology, applied in the direction of presses, presses using rotating pressure components, manufacturing tools, etc. The pressing device cannot adjust the width and other problems, so as to achieve the effect of wide application range, reasonable structure and practical rolling device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

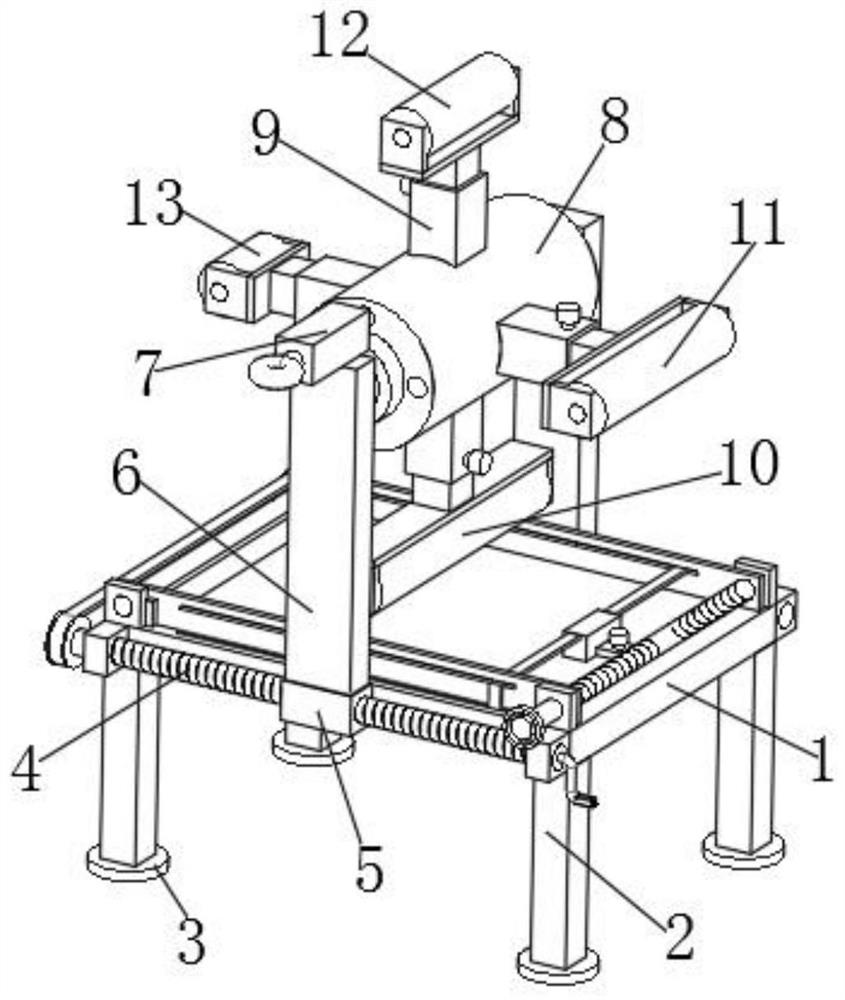

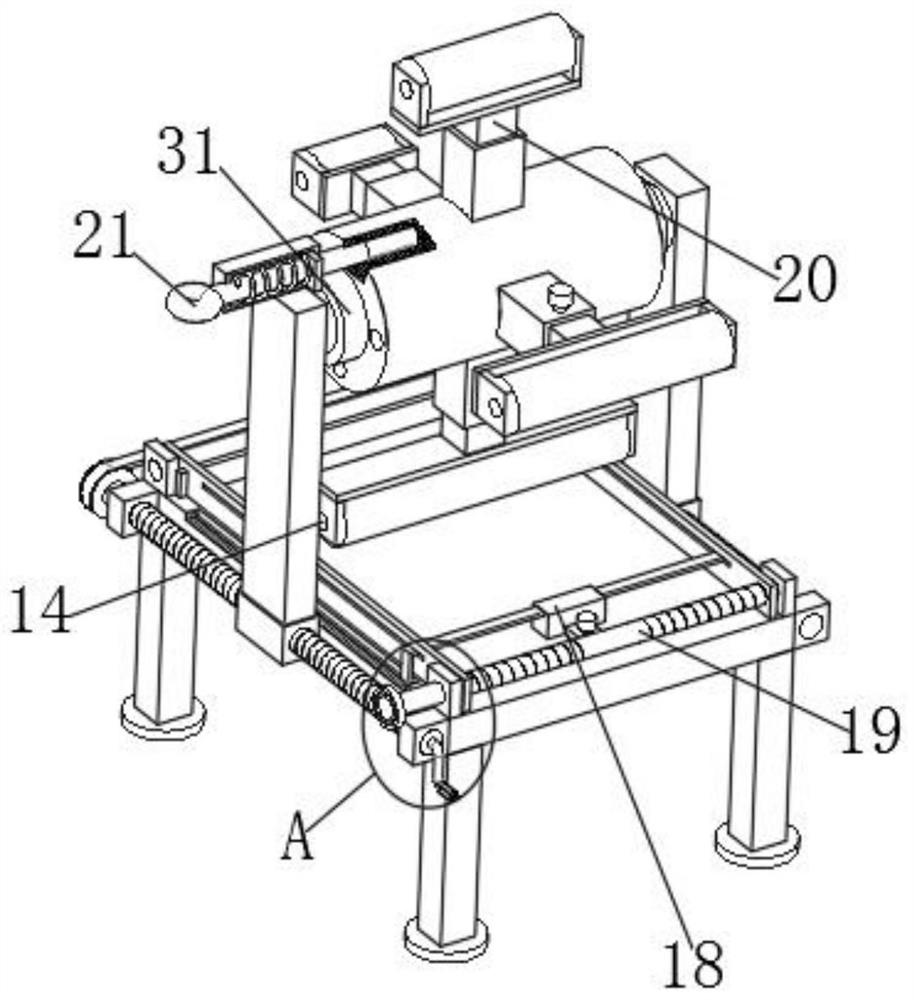

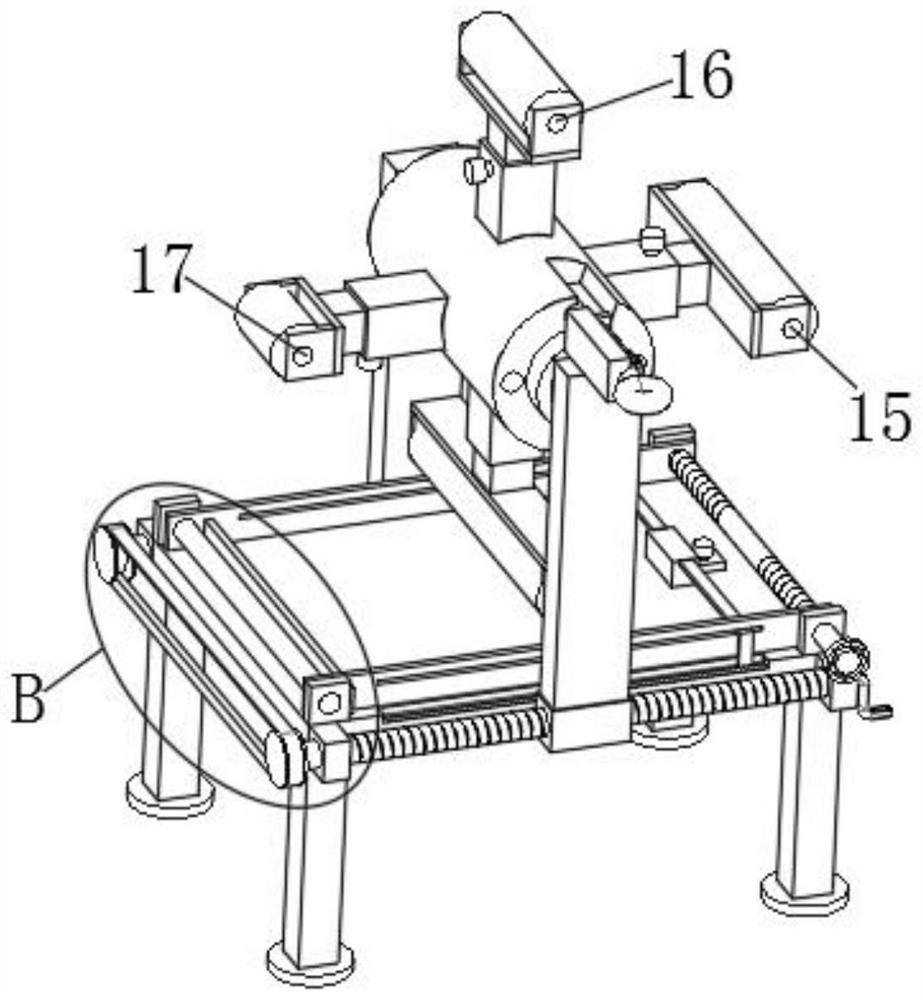

[0041] Example: Reference Figure 1-8 A width-adjustable composite polycrystalline mullite fiberboard rolling device shown includes a rolling table 1, and the top of the rolling table 1 is fixedly connected with a clamping plate 38 and four mounting blocks 25, and the clamping plate 38 is connected with the rolling plate. The top of table 1 is fixed by welding, and the top of mounting block 2 and rolling table 1 are fixed by welding. The side walls of the four mounting blocks 25 are all provided with mounting holes, and the inner walls of the mounting holes are provided with clamping parts. There is a fixed part on the top of the rolling table 1. There are two slide grooves on the top of the rolling table 1. There are four fixed blocks 26 fixedly connected to the side wall of the rolling table 1. The fixed blocks 26 are welded to the side wall of the rolling table 1. Fixed, the side walls of the four fixed blocks 26 are provided with screw holes, the inwalls of the four screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com