Prosthesis component and method for manufacturing same

A manufacturing method and component technology, applied in the field of prosthetic components and their manufacturing, can solve problems such as easy loosening, and achieve the effects of preventing fragmentation and reducing the generation of friction debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

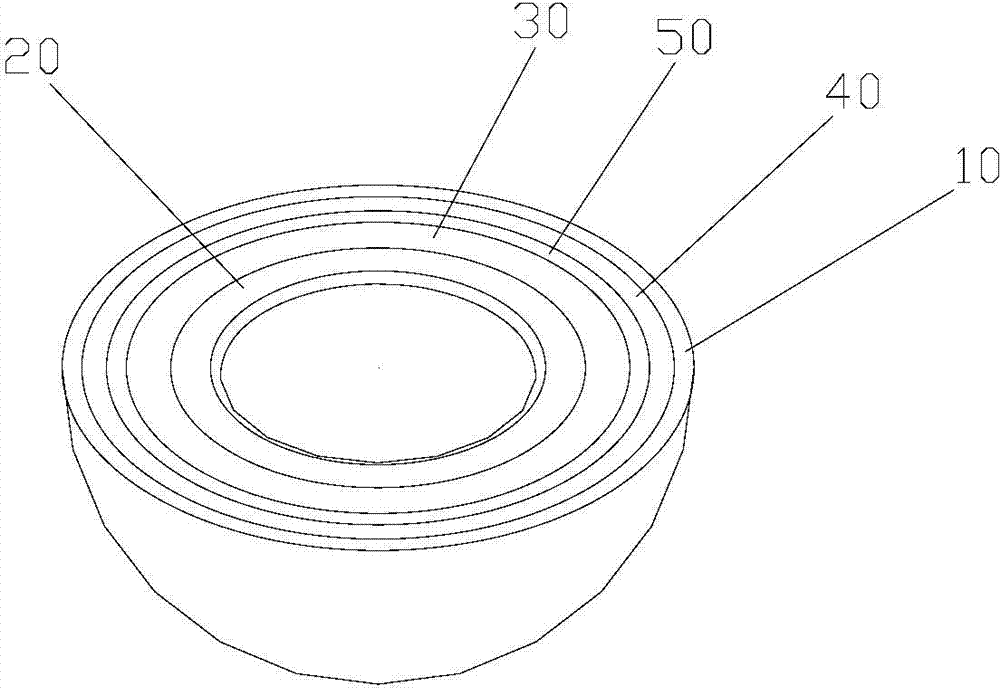

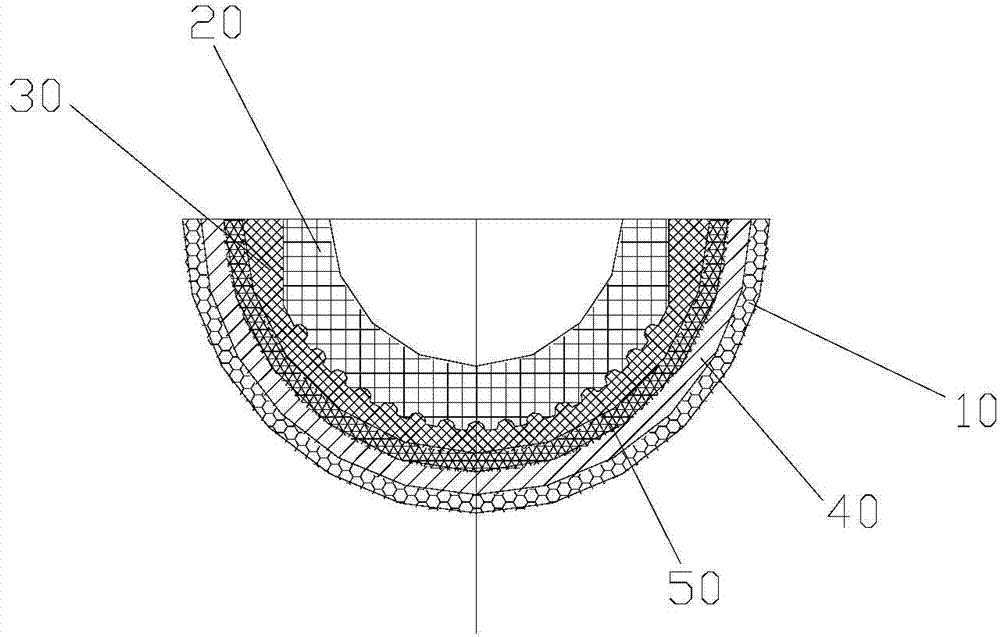

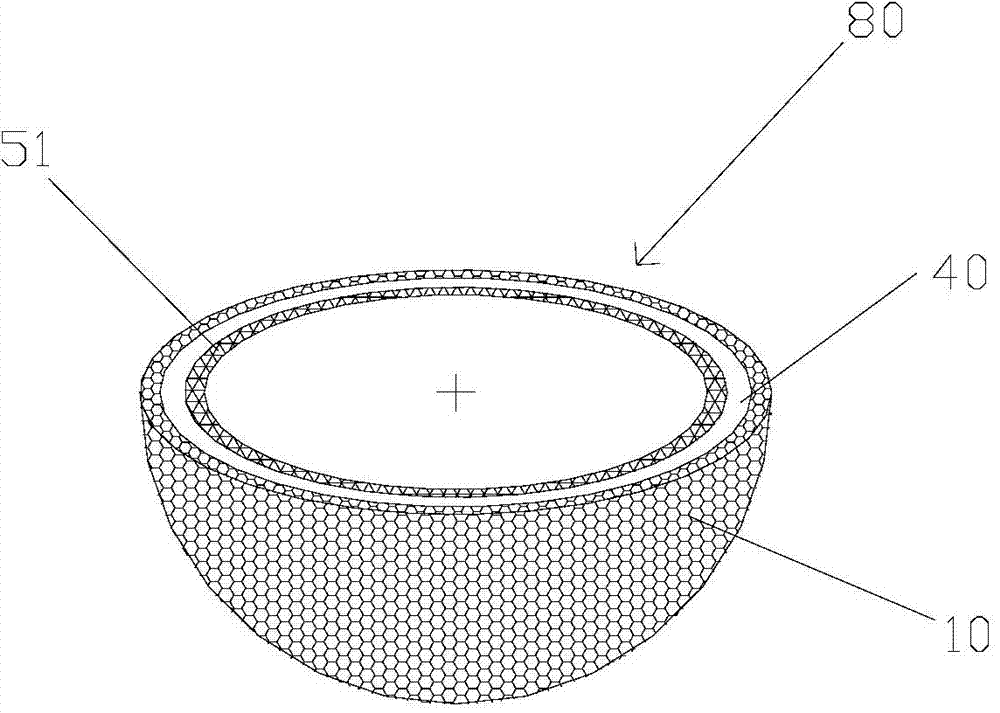

[0047] In the prior art, the artificial hip joint prosthesis is mainly divided into an acetabular component and a femoral component (including the femoral head). Among them, the acetabular component is usually an ultra-high molecular weight polyethylene acetabular cup (bone cement fixation type) or a metal acetabular cup and an ultra-high molecular weight polyethylene liner arranged inside it (biological fixation type). The femoral component is usually composed of a femoral stem and a metal ball head arranged on its top. The above metal ball head cooperates with the inner ball socket of the ultra-high molecular weight polyethylene lining to form a joint friction surface to realize the rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com