Mixed jet generation method and drainage structure thereof

A technology of jet flow and fluid flow rate, which is applied in the direction of mixing methods, mixers, fluid mixers, etc., can solve the problems of large water consumption, incomplete decontamination, and slow decontamination speed of decontamination nozzles, so as to improve the decontamination effect , high versatility, and the effect of increasing water volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

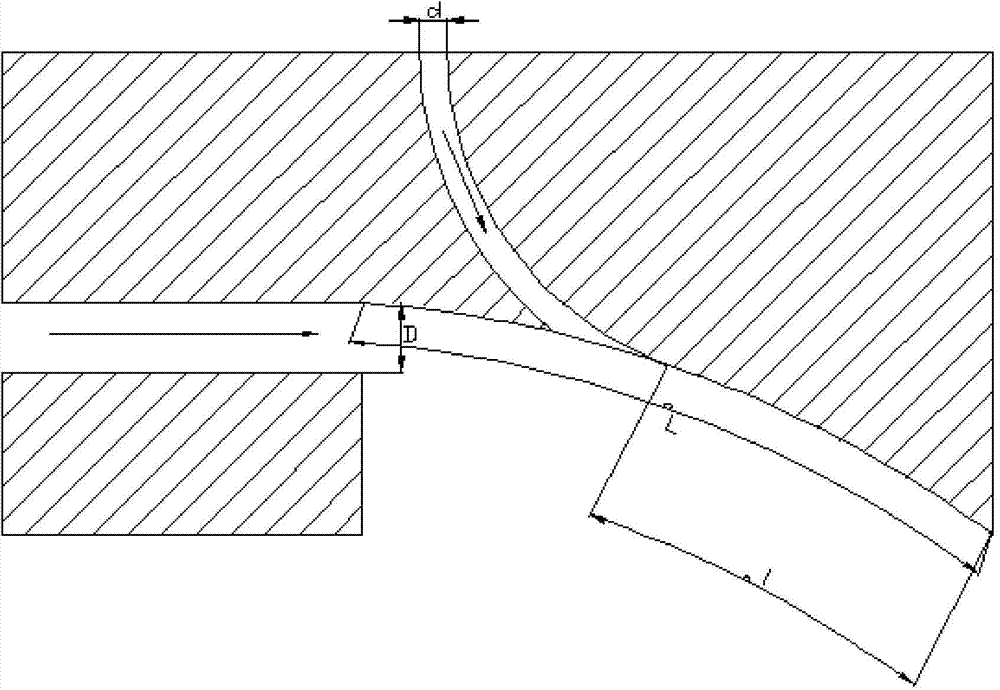

[0041] Such as figure 1 As shown, this structure is a jet drainage structure including a liquid medium flow guide and a gas medium flow guide, mainly including the air flow nozzle, the decontamination liquid nozzle and the confluence arc surface, the arc of the confluence arc surface is 35°, the arc The length is L, the radius is R, the air flow nozzle (jet port of B medium guide piece) is located at one end of the confluence arc surface, and the decontamination liquid nozzle (A medium guide piece jet port) on the confluence arc surface, decontamination The arc length between the liquid nozzle and the air nozzle is l;

[0042] The gap width of the airflow spout (jet outlet of medium guide member B) is D, and the gap width of the decontamination nozzle (jet outlet of medium guide member A) is d, where D is greater than d;

[0043] The air flow nozzle includes an upper surface and a lower surface. The upper surface is connected to the confluence arc surface through an arc surfa...

Embodiment 2

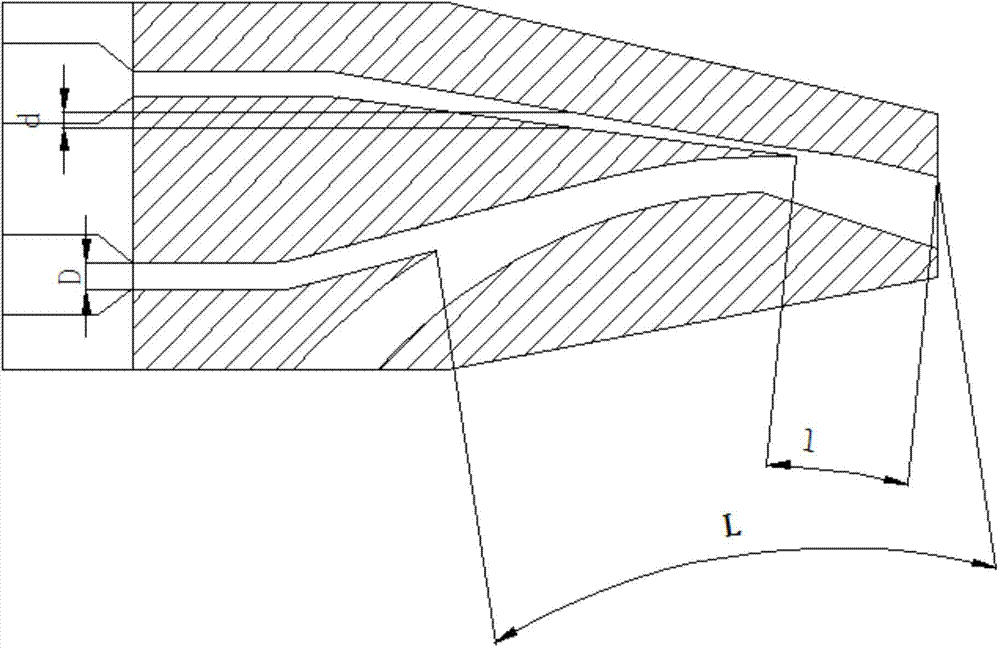

[0048] Such as figure 2 As shown, this structure includes a nozzle main body, and two parallel connecting pipes are arranged at the tail of the nozzle main body. A flow pipe, wherein the liquid flow medium guide pipe is located at the upper part of the air flow medium guide pipe, and a main flow channel is also arranged at the lower part of the air flow medium guide pipe and the liquid flow medium guide pipe;

[0049] The main flow channel is formed by two arc-shaped surfaces C at intervals. Between the two arc-shaped surfaces C is the main flow guide channel. The main flow guide channel mainly includes a drainage section and a confluence section. The outlet of the medium diversion pipe is located on the diversion section, and the high-pressure fluid ejected from the air medium diversion pipe and the liquid flow medium diversion pipe converge at the confluence section, wherein the width of the confluence section is much larger than that of the diversion section;

[0050] The...

Embodiment 3

[0056] Changing the flow rate of the gas medium fluid and the liquid medium fluid by changing the working load of the gas medium fluid and the liquid medium fluid driving the pump;

[0057] By adjusting the flow rate of the gas medium fluid to be A, wherein because the diameter of the air flow nozzle is constant, there is a linear relationship between the flow rate and the flow rate;

[0058] By adjusting the liquid medium fluid, the flow rate is B, wherein because the diameter of the liquid flow nozzle is also constant, there is a linear relationship between the flow rate and the flow rate;

[0059] At this time, adjusting the mixing relationship between A and B can obtain mixed jets in different states.

[0060] 1. Adjust A so that A is greater than 0, and B is adjusted to be equal to 0. At the same time, A must meet the resistance along the surface of the confluence arc surface. At this time, a thin surface-shaped gas fluid of pure gas will be obtained, which can be mainly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com