Method for blanking cylindrical formwork at joint part of V-shaped cylinder

A column and formwork technology, applied in the field of cylindrical formwork blanking at "V"-shaped cylindrical joints, can solve the problems of high cost of steel formwork and transportation, high technical requirements for construction, and impact on project quality, and achieves flexible cutting and easy quality. Guaranteed, the effect of low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

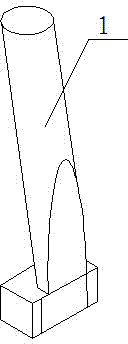

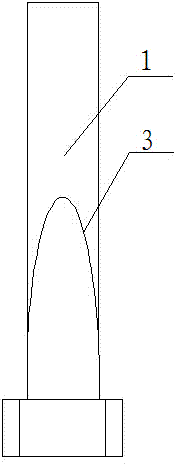

[0033] Example: see Figure 1-Figure 5 , the present embodiment is thick with 18mm, the long semicircular arc wooden formwork of 3m as cylindrical formwork.

[0034] A method for blanking a cylindrical formwork at a "V"-shaped cylindrical node position, comprising the following steps:

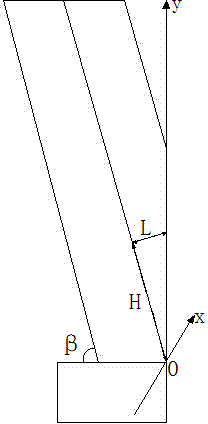

[0035] S1: The cylindrical formwork at the "V"-shaped cylindrical node part is composed of two cylindrical formworks (the cylindrical formwork is hollow), the lower half of the two cylindrical formworks are combined into one, and the joint part of the bottom of the two cylindrical formworks The contour is a semi-ellipse; use BIM technology to establish a three-dimensional view of the "V"-shaped cylinder, cut the intersecting line for data analysis, and obtain the cutting contour line of the "V"-shaped cylindrical formwork shown in the form of a semi-ellipse.

[0036] S2: Carry out cutting on the cylindrical formwork, the method that the contour line of the cutting surface is a semi-ellipse is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com