Processing equipment for fireproof cross-band veneer

A technology of processing equipment and fireproof core, which is applied in the field of processing equipment for fireproof core boards, can solve the problems of no production equipment and achieve the effect of convenient pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

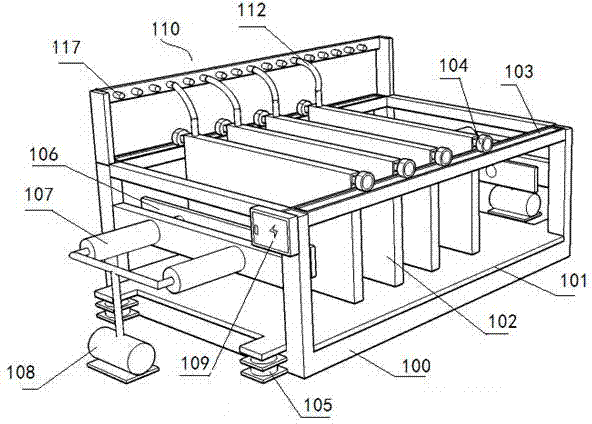

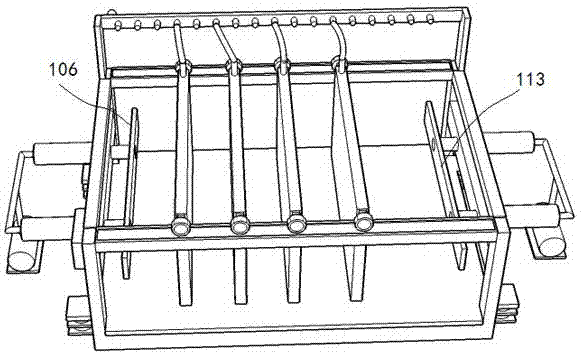

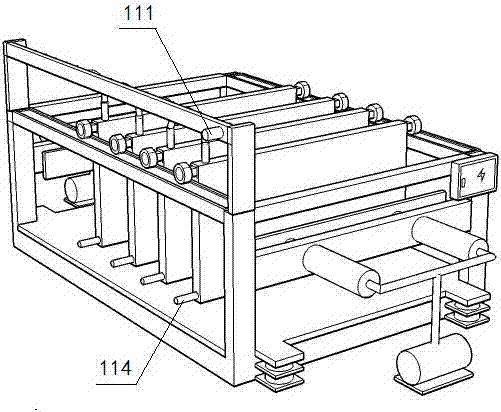

[0021] see Figure 1~5 , an integrally formed fireproof core board processing equipment, including a frame 100, a horizontal lifting table 101 is arranged inside the frame, and at least two Sliding thermoformed thermal insulation board 102, the thermoformed zone is between every two thermoformed thermal insulation boards, the thermoformed thermal insulation board is vertically arranged with the lifting workbench, and each thermoformed thermal insulation board is provided with a hot water Circulation pipe 116; the two sides of the frame are respectively provided with a left top plate 106 and a right top plate 113, and the left top plate and right top plate are pushed by the top tightening mechanism to press the heat-forming insulation board and the workpiece to be processed for f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com