Control method for printing system

A control method and a technology of a printing system, applied to printing devices, printing, etc., can solve problems that affect printing progress, affect user use, and fail to protect the printer head from cooling, achieve the best printing effect, consistent effect, and simple and easy control method line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Correct the printing parameters according to the superimposed value of the voltage parameter and the ambient temperature parameter.

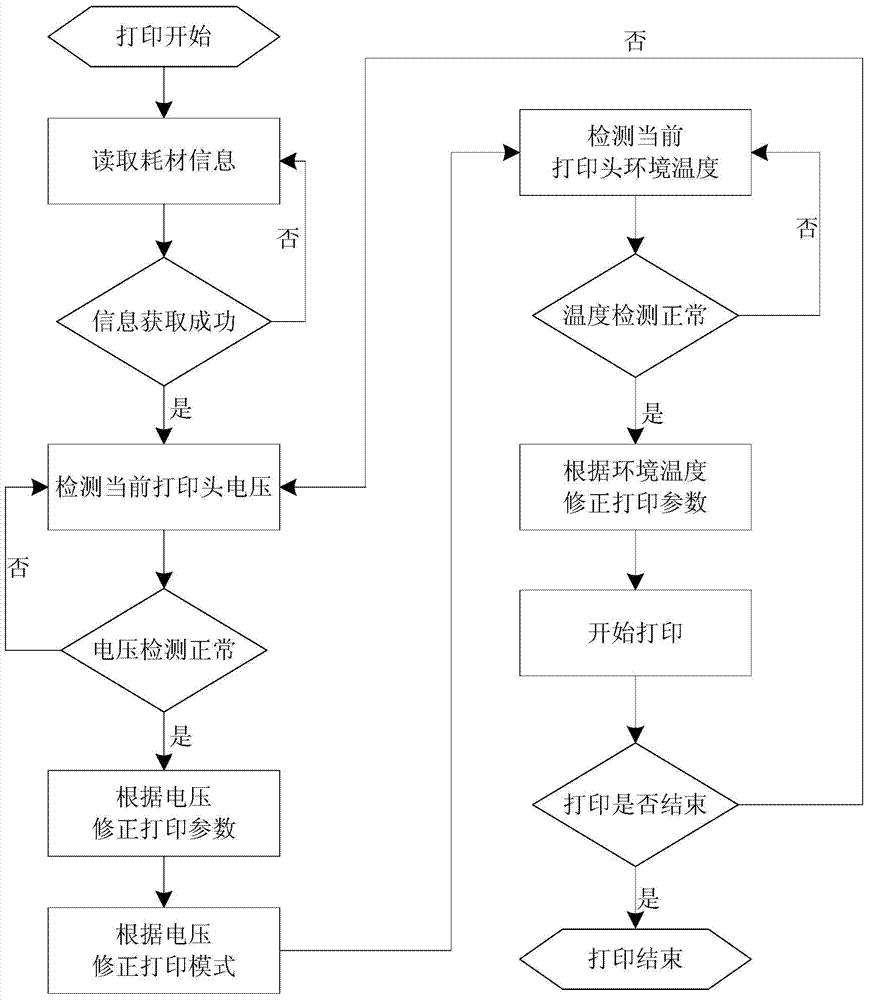

[0060] A printing system control method, such as figure 1 shown, including the following steps:

[0061] (1) Start printing, read the consumables information, and obtain the printing media information. After the information fails to be obtained, read the consumables information again until the printing information is obtained successfully. Correspondingly, the paper printing media corresponds to the standard printing parameters of the paper media, and the film type The printing medium corresponds to the standard printing parameters of film media;

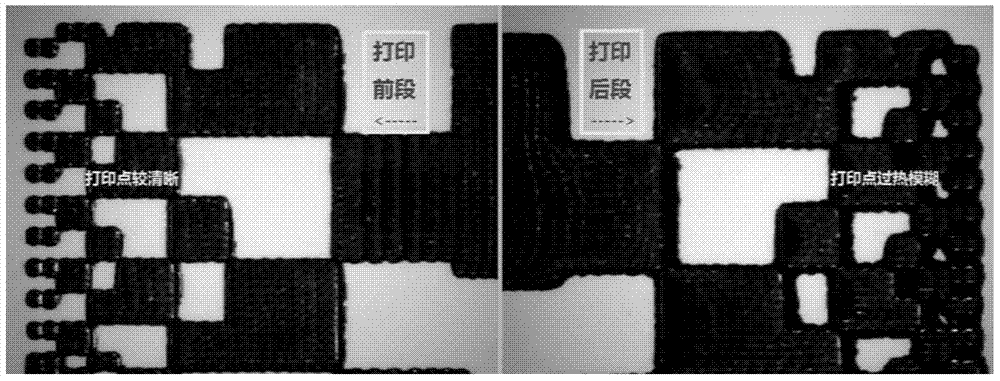

[0062] (2) Detect the current voltage parameter of the print head. If the voltage detection is abnormal, re-detect the current voltage parameter. If the voltage detection is normal, compare the current voltage parameter with the standard printing parameter of the printing medium to obtain the ...

Embodiment 2

[0070] The printing parameters are corrected with the change value of the voltage parameter.

[0071] A printing system control method, comprising the following steps:

[0072] (1) Start printing, read consumable information, obtain printing medium information, and read consumable information again after information acquisition fails until printing information is successfully obtained. Correspondingly, different printing media correspond to different standard printing parameters;

[0073] (2) Detect the current voltage parameters of the print head. If the voltage detection is abnormal, re-detect the current voltage parameters. If the voltage detection is normal, compare the current voltage parameters with the standard printing parameters of the printing medium to obtain the change value of the voltage parameters. According to the voltage parameters Change the value to modify the printing parameters and printing mode. If the voltage value increases, the heating time of the prin...

Embodiment 3

[0076] The printing parameters are corrected with the changing values of the ambient temperature parameters.

[0077] A printing system control method, comprising the following steps:

[0078] (1) Start printing, read consumable information, obtain printing medium information, and read consumable information again after information acquisition fails until printing information is successfully obtained. Correspondingly, different printing media correspond to different standard printing parameters;

[0079] (2) Detect the current ambient temperature parameters of the print head. If the ambient temperature detection is abnormal, re-detect the current ambient temperature parameters. If the ambient temperature detection is normal, compare the current ambient temperature parameters with the standard printing parameters of the printing medium to obtain the ambient temperature parameter changes. Value, modify the printing parameters and printing mode according to the change value of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com