Automatic oiling machine of electric construction elevator

A construction elevator, electric technology, applied in elevators, transportation and packaging, etc., can solve the problems of complex structure, inconvenient installation and use, large reduction ratio, etc., and achieve the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

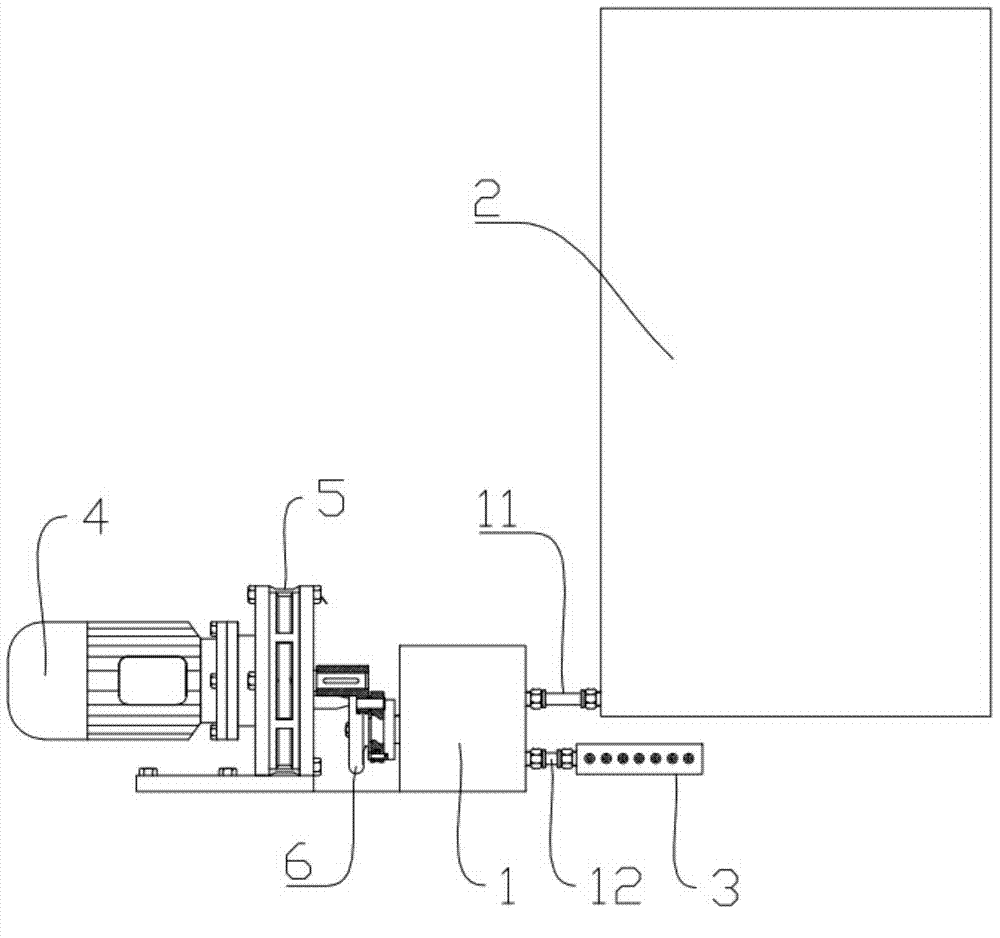

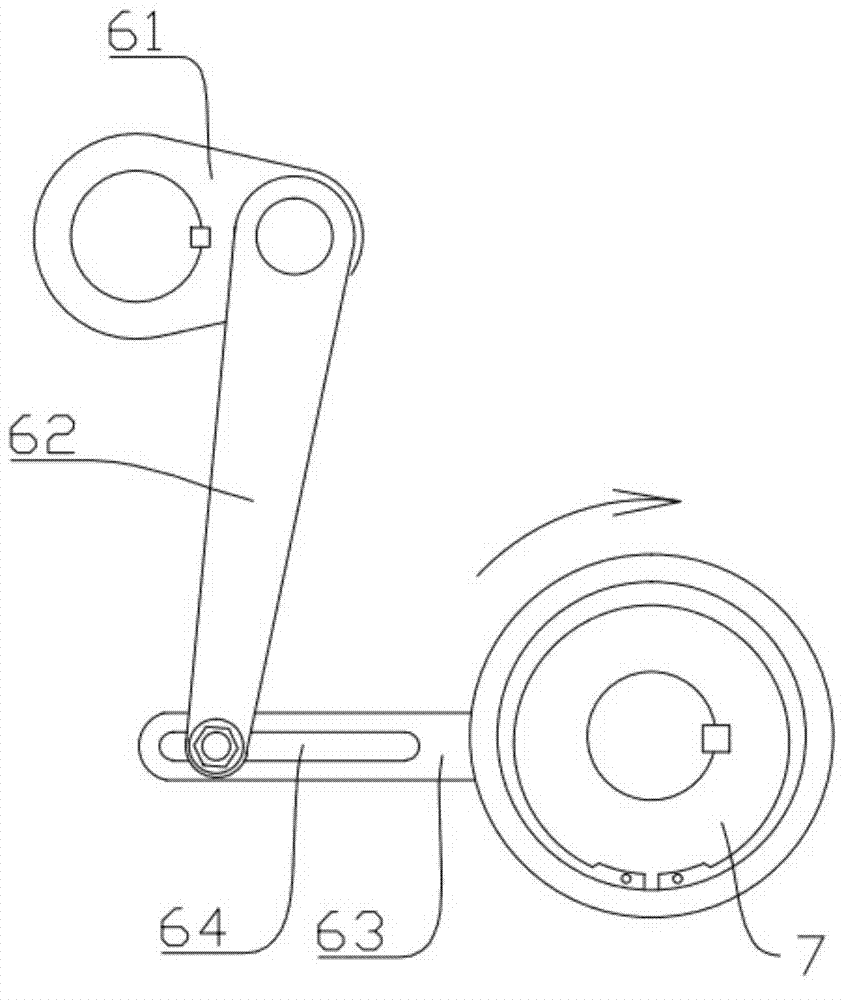

[0033] Embodiment one sees Figure 1 to Figure 3 , comprising an oil pump 1, an oil tank 2, an integrated diverter block 3, a motor 4, and a reducer 5 connected to the output shaft of the motor 4, the oil suction end 11 of the oil pump 1 communicates with the oil tank 2, and the oil pump 1 The oil outlet 12 communicates with the integrated diverter block 3, and the reducer 5 is connected to the oil pump 1 through a transmission assembly. It is characterized in that the oil pumping system formed by the transmission assembly and the oil pump 1 is different in the direction of rotation of the reducer 5 The oil can be pumped out under the condition that the transmission assembly includes a crank-link transmission mechanism 6, the output end of the crank-link transmission mechanism 6 is a one-way bearing 7, the oil pump 1 is a gear pump, and the speed reducer 5 At the same time, it follows the forward and reverse rotation of the motor 4; regardless of the rotation of the front stag...

Embodiment 2

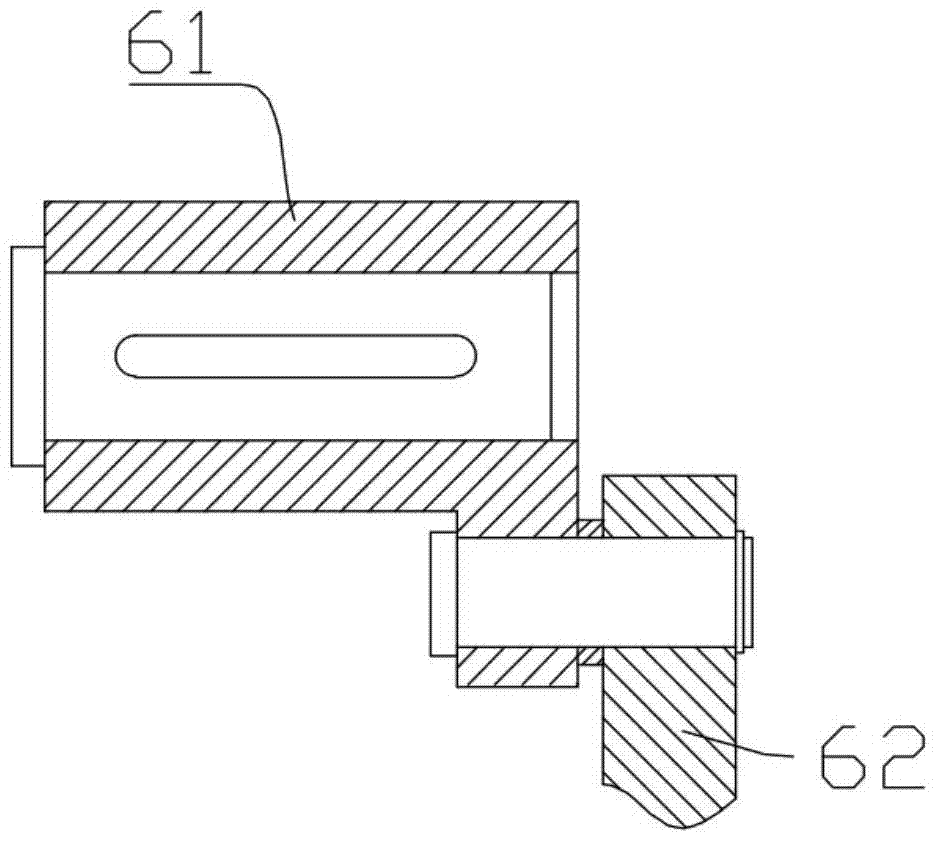

[0038] Embodiment two see Figure 4 to Figure 6 , comprising an oil pump 1, an oil tank 2, an integrated diverter block 3, a motor 4, and a reducer 5 connected to the output shaft of the motor 4, the oil suction end 11 of the oil pump 1 communicates with the oil tank 2, and the oil pump 1 The oil outlet 12 communicates with the integrated diverter block 3, and the reducer 5 is connected to the oil pump 1 through a transmission assembly. It is characterized in that the oil pumping system formed by the transmission assembly and the oil pump 1 is different in the direction of rotation of the reducer 5 The oil can be pumped out under the condition that the transmission assembly includes a crank-link transmission mechanism 6, the output end of the crank-link transmission mechanism 6 is a connecting rod 62, and the oil pump 1 is a plunger pump, and the connecting rod 62 directly pushes the plunger pump, and finally transports it to each lubrication point through the integrated diver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com