A flexible anti-freezing and thawing treatment method for expansion joints of expressway bridges in seasonally frozen soil regions

A technology of expressway and treatment method, applied in bridges, bridge parts, bridge maintenance, etc., can solve problems such as poor maintenance effect and damage to expansion joints of highway bridges, achieve simple technology, prevent water seepage and soil leakage, and improve anchorage performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

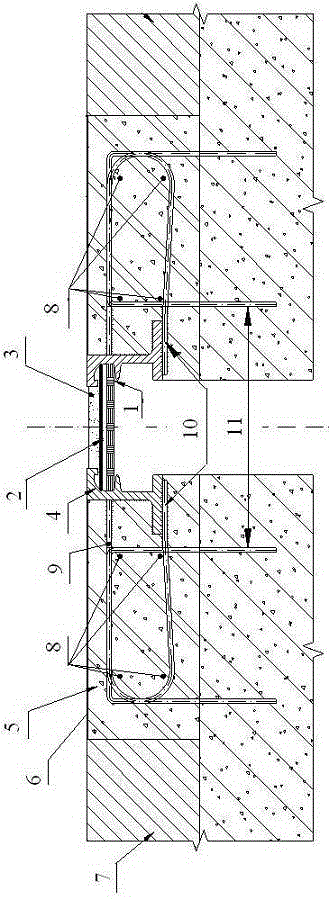

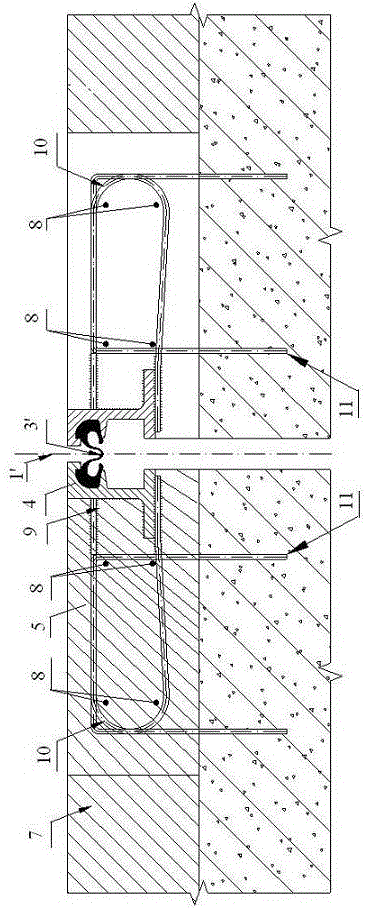

Image

Examples

Embodiment 1

[0045] Include the following steps:

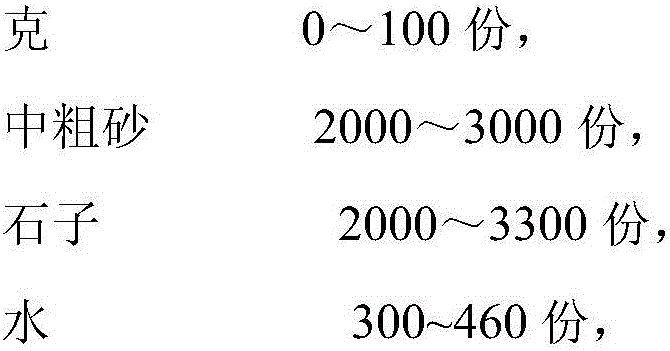

[0046] 1. Chisel out the damaged concrete in the original anchorage area, remove the original concrete material, and pour high-performance anti-corrosion concrete 5. The high-performance anti-corrosion concrete includes the following raw materials in parts by weight:

[0047]

[0048] The composite material comprises the following raw materials in parts by weight:

[0049]

[0050] (2) Flexible filling material between the expansion joints of side beams

[0051] (1) Use a steel wire brush to brush the liquid steel surface rust removal and phosphating agent between the Mauler expansion joints of the side beams, rust removal and phosphating, once;

[0052] The liquid iron and steel surface derusting and phosphating agent is composed of the following raw materials in parts by mass:

[0053]

[0054] (2) Remove the residue on the surface of the Mauler expansion joint, and apply the interface agent;

[0055] Described interfacial ag...

Embodiment 2

[0071] Include the following steps:

[0072]1. Chisel out the damaged concrete in the original anchorage area, remove the original concrete material, and pour high-performance anti-corrosion concrete 5. The high-performance anti-corrosion concrete includes the following raw materials in parts by weight:

[0073]

[0074] The composite material comprises the following raw materials in parts by weight:

[0075]

[0076] (2) Flexible filling material between the expansion joints of side beams

[0077] (1) Use a steel wire brush to brush the liquid steel surface rust removal and phosphating agent between the Mauler expansion joints of the side beams, rust removal and phosphating, once;

[0078] The liquid iron and steel surface derusting and phosphating agent is composed of the following raw materials in parts by mass:

[0079]

[0080] (2) Remove the residue on the surface of the Mauler expansion joint, and apply the interface agent;

[0081] Described interfacial age...

Embodiment 3

[0098] Include the following steps:

[0099] 1. Chisel out the damaged concrete in the original anchorage area, remove the original concrete material, and pour high-performance anti-corrosion concrete 5. The high-performance anti-corrosion concrete includes the following raw materials in parts by weight:

[0100]

[0101] The composite material comprises the following raw materials in parts by weight:

[0102]

[0103]

[0104] (2) Flexible filling material between the expansion joints of side beams

[0105] (1) Use a wire brush to brush the liquid steel surface rust removal and phosphating agent between the Maole expansion joints of the side beams, rust removal and phosphating, twice;

[0106] The liquid iron and steel surface derusting and phosphating agent is composed of the following raw materials in parts by mass:

[0107]

[0108] (2) Remove the residue on the surface of the Mauler expansion joint, and apply the interface agent;

[0109] Described interfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com