Closestool flushing control method

A control method and technology for toilets, which are applied to flushing equipment with water tanks, flushing toilets, water supply devices, etc., can solve the problems of insufficient flushing force, large water consumption, waste, etc., and achieve volume and weight reduction. The effect of reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

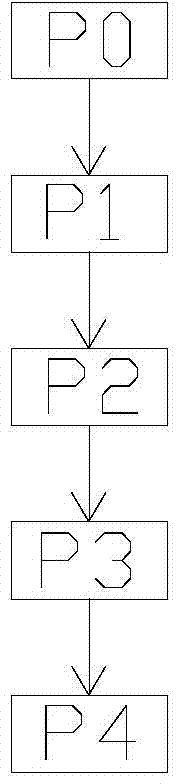

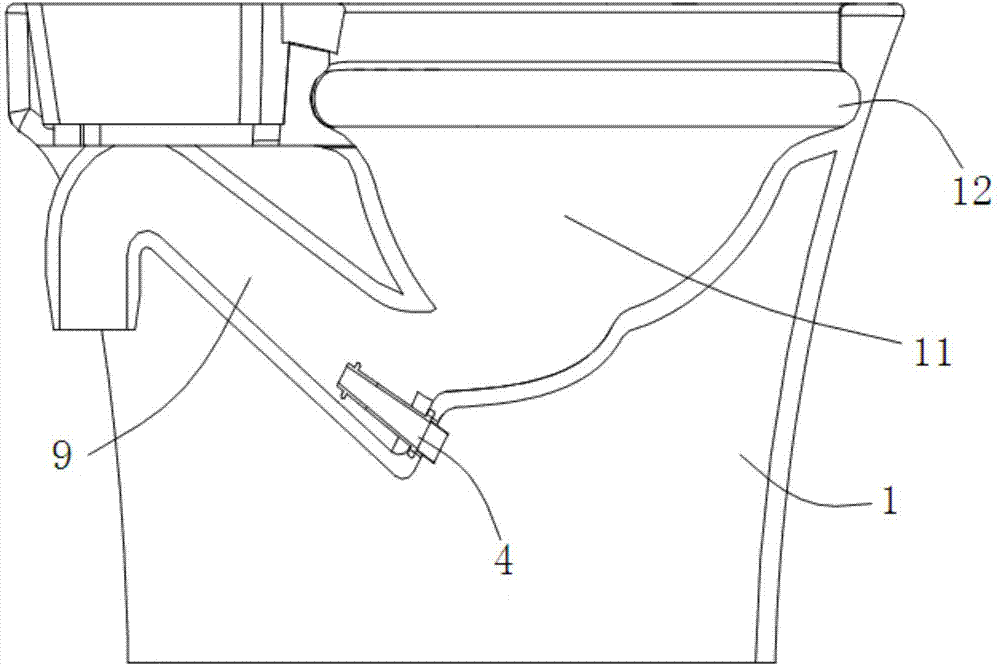

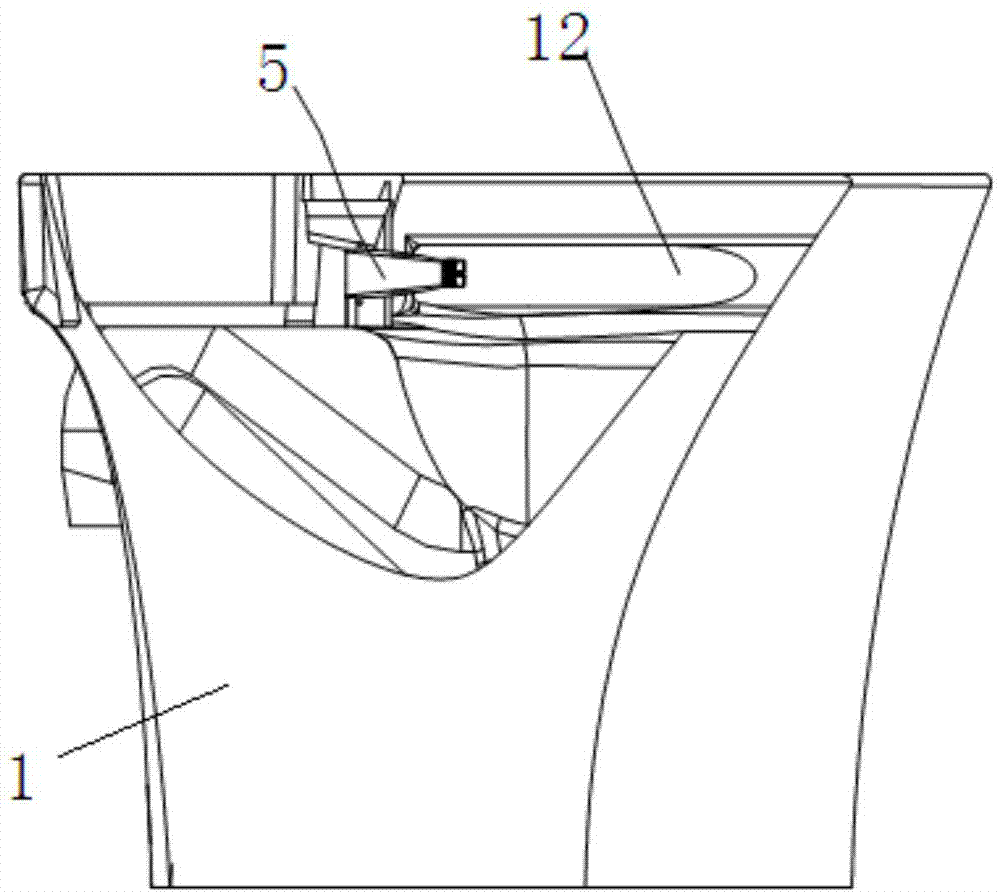

[0027] Such as Figures 1 to 4 Shown: the flushing control method of the toilet of the present embodiment, comprises the following steps:

[0028] P1: trigger the flush switch 22 provided on the toilet 1; the flush switch 22 can be a mechanical button or an automatic sensing part;

[0029] P2: The electric control valve II 24 located in the flushing pipe II is opened, and the electric control valve II 24 is kept in the open state for M seconds and then closed; The water outlet II is connected;

[0030] P3: When the electric control valve II24 is closed, the electric control valve I23 provided in the flushing pipe I is opened, and the electric control valve I23 is kept open for N seconds and then closed; the flushing pipe I is connected to the water supply pipe network and connected with The water outlet I at the sewage channel 9 is connected;

[0031] P4: When the electric control valve I23 is turned off, the electric control valve II24 is opened, and the open state of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com