Two-on-one heavy type gas-steam combined cycle unit AGC control method

A combined cycle unit and control method technology, which is applied to steam engine installations, mechanical equipment, machines/engines, etc., can solve the problems of complex thermal system structure and achieve the effect of stable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The implementation of the present invention will be described in further detail below with reference to the accompanying drawings. The following embodiments are only descriptive and not restrictive, and the protection scope of the present invention cannot be limited by this.

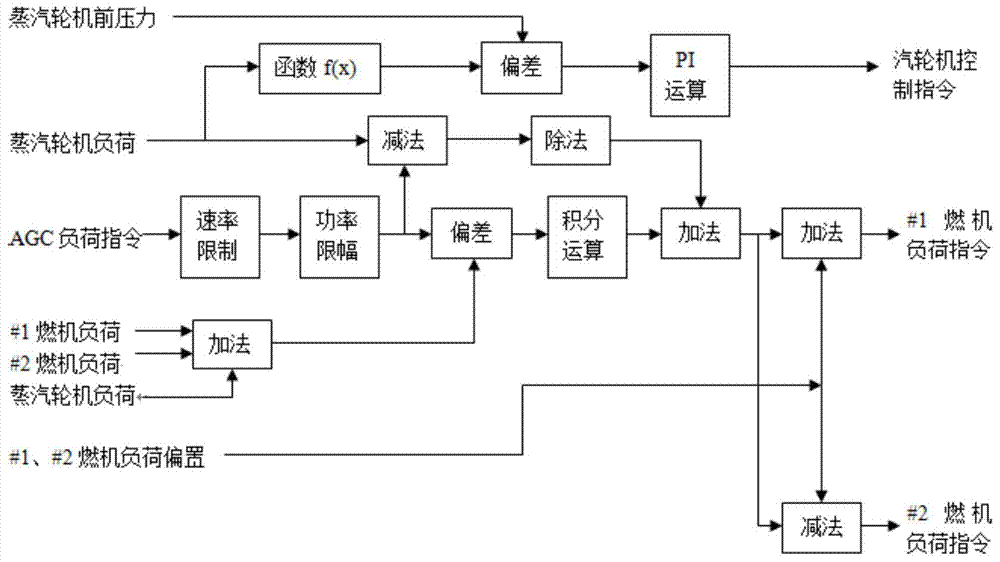

[0019] A two-to-one heavy-duty gas-steam combined cycle unit AGC control method, such as figure 1 As shown, including the method steps are as follows:

[0020] (1) The intermediate AGC load command accepted by the generator set load management center is processed by the rate limiting module to limit the speed and the power limiting module to limit the actual load command. The rate limiting module changes the input unit load command signal rate It is limited to the range of 0-4% of the rated load of the unit. The power limiting module limits the power of the input signal to the range of 40%-100% of the rated load of the complete unit to ensure that the load change rate and amplitude of the unit are with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com