Code wheel fault self-diagnosis method for photoelectric absolute value encoder

An absolute value encoder and self-diagnosis technology, applied in the encoder field, can solve problems such as limited working temperature range, user crisis, code disc eccentricity, etc., and achieve the effect of convenient maintenance and judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the specific embodiments.

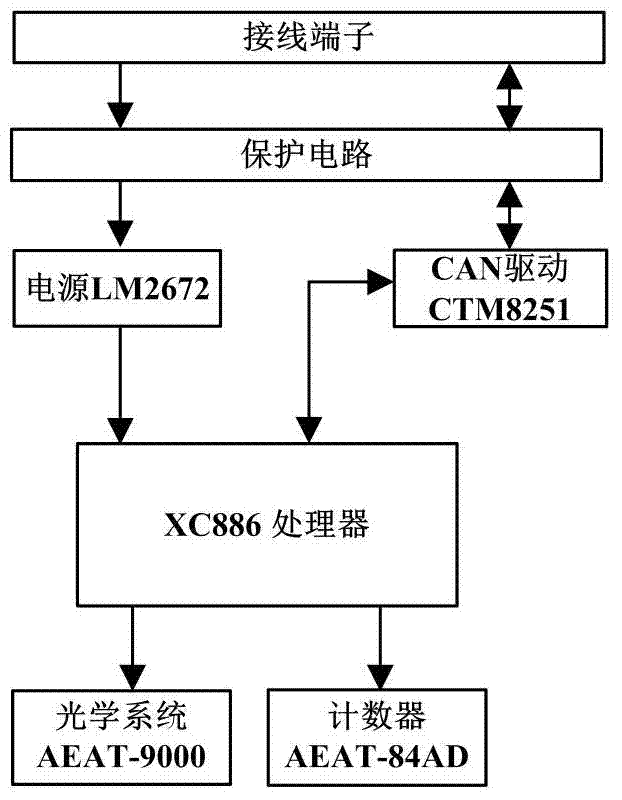

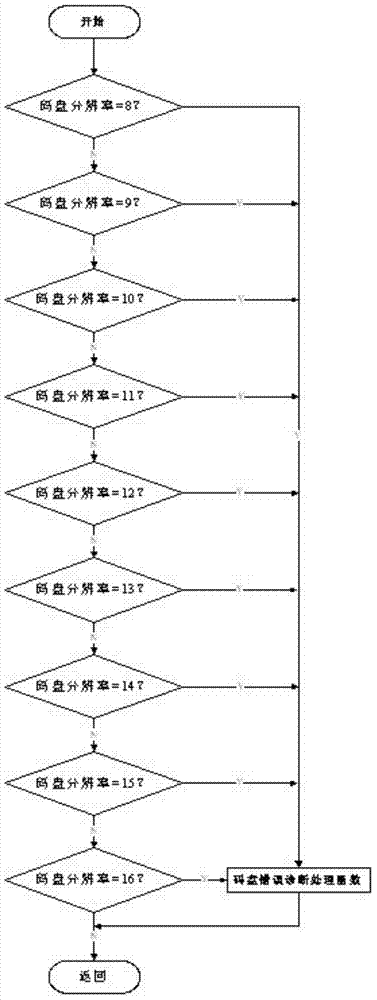

[0028] see figure 1 and Figure 4 , A code disc fault self-diagnosis method of a photoelectric absolute value encoder according to the present invention includes a processor, an optical system, a counter, a power supply, a transceiver, a protection circuit and a connection terminal.

[0029] The processor adopts Infineon XC886 processor, which has strong anti-interference ability and good stability; optical components and counters are all mature modules of Avago, which have large market circulation and good reliability; communication The module adopts the CAN transceiver chip of Zhougong with DC 2500V isolation function.

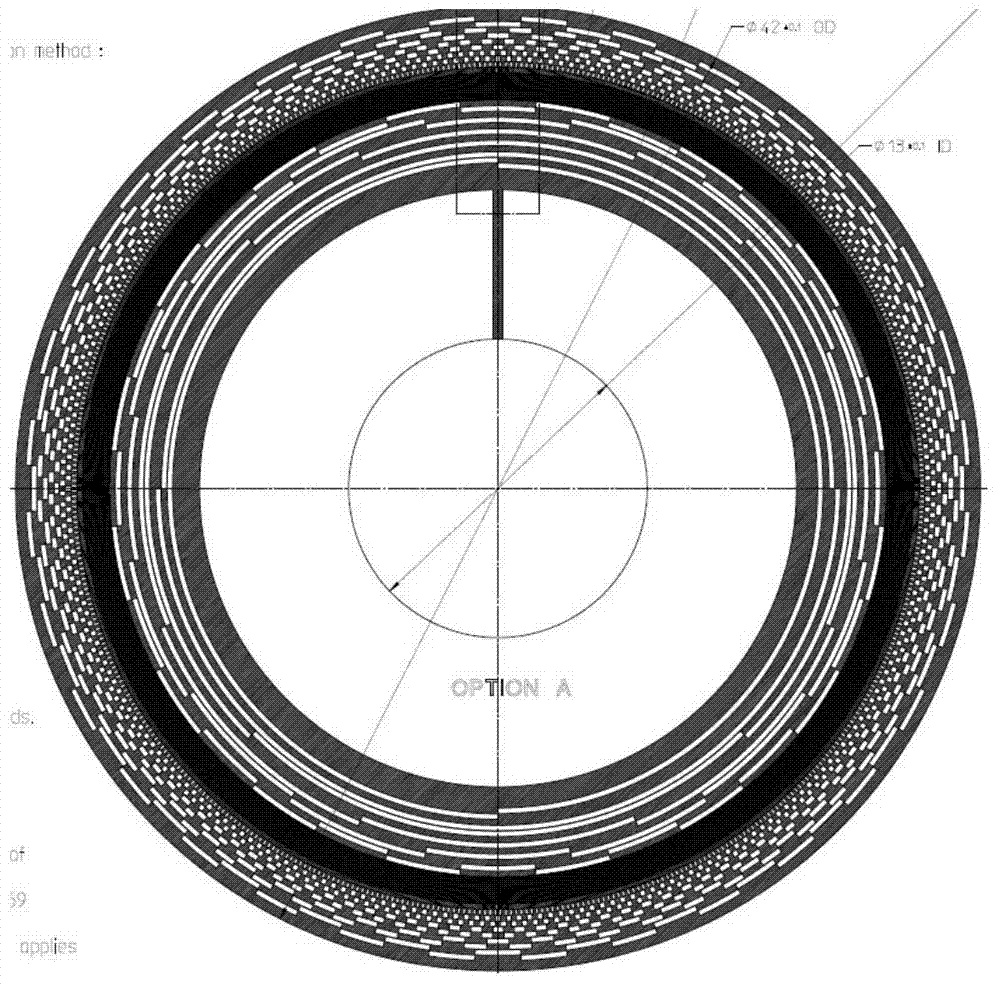

[0030] The absolute value code wheel is a rotating disk with several transparent and opaque windows, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com