Laminated vibration columnar bottom sampler

A dredger and vibrator technology, applied in sampling devices and other directions, can solve the problems of high price, universal influence, difficulty, etc., and achieve the effects of strong representativeness, convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

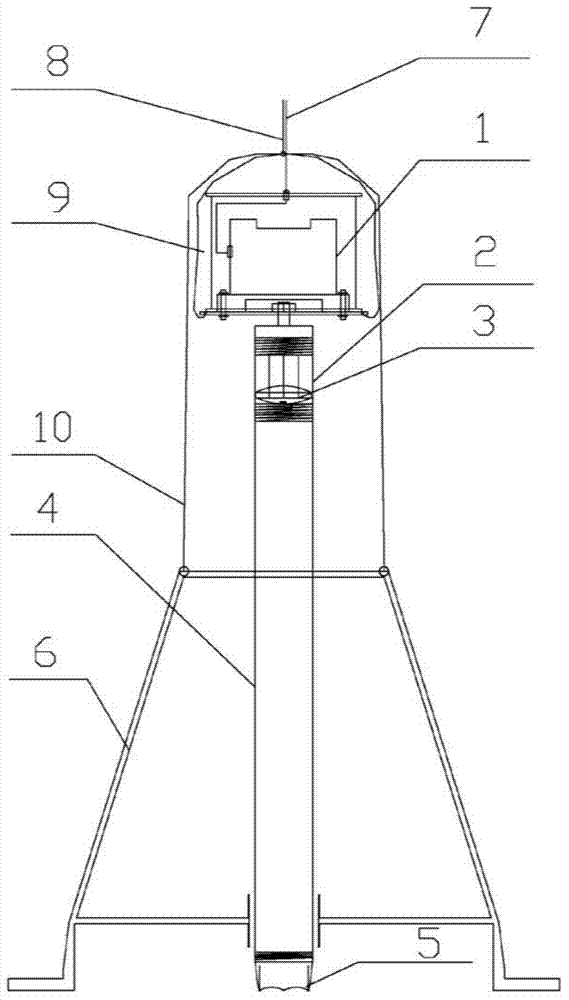

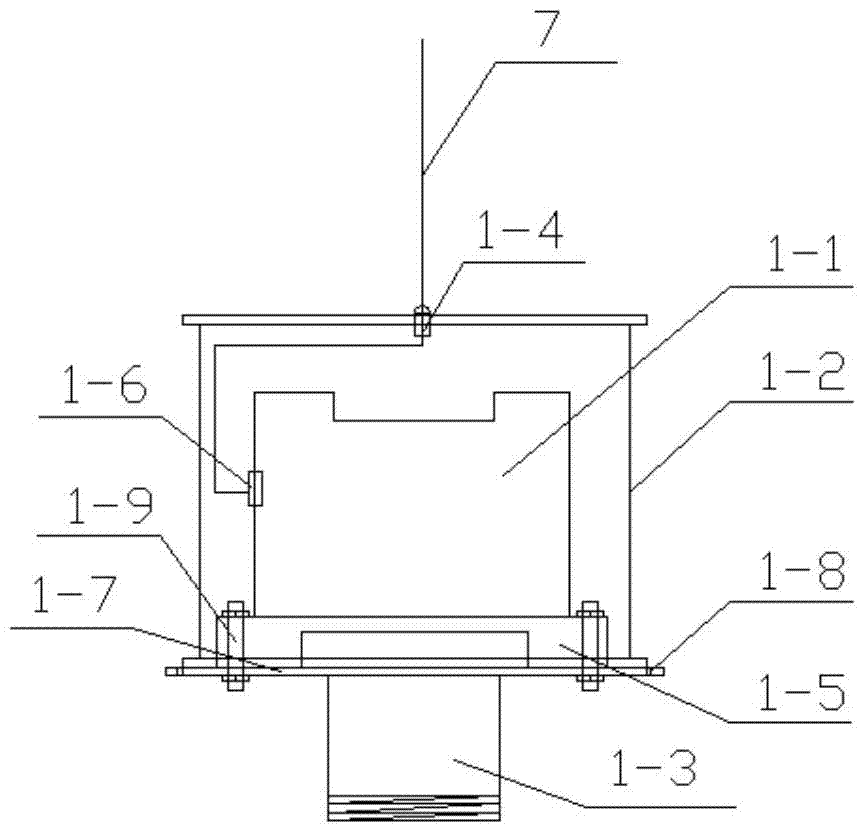

[0021] The specific implementation manners of the present invention will be described in detail below in conjunction with the technical solutions (and accompanying drawings).

[0022] The specific implementation steps of the bedding vibrating columnar dredger are as follows:

[0023] Step 1: Put the self-balancing sealer 3 into the drain head 2.

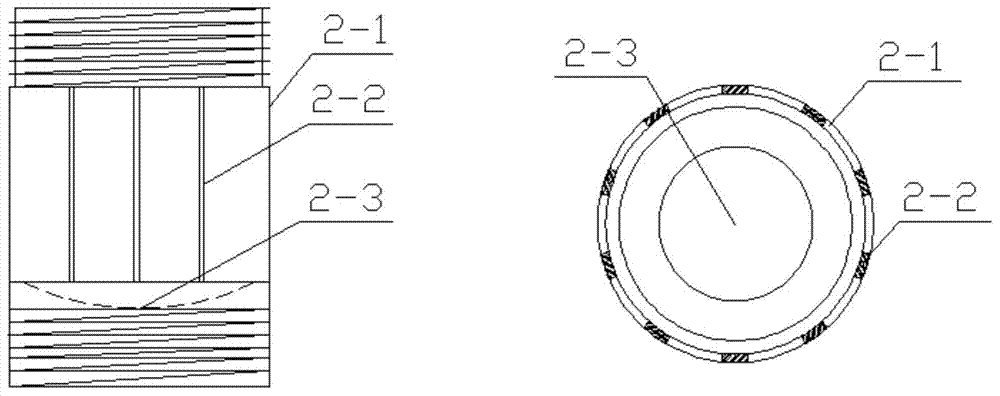

[0024] Step 2: Connect the vibrating mechanism 1, drain head 2, sampling pipe 4, and sampling head 5 with threaded connections. Both ends of the sampling pipe 4 have threads, which can be combined and lengthened according to needs, or a separate sampling inner pipe 4-2 can be selected. Used in combination, and the connected whole is inserted into the stable bracket 6.

[0025] Step 3: Tie the vibrator cable 9 and the stabilizer cable 10 to the rope holes 1-8 and the rope buckle B6-5 respectively, and connect with the graduated cable 8 through its own rope buckle A to form the pulling force of the acquisition device system.

[0026...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com