Device and method for measuring parallelism of ion beam flow

An ion beam, parallelism technology, applied in the direction of discharge tubes, electrical components, circuits, etc., can solve the problems of inconvenience, high cost, inaccurate judgment results, etc., and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

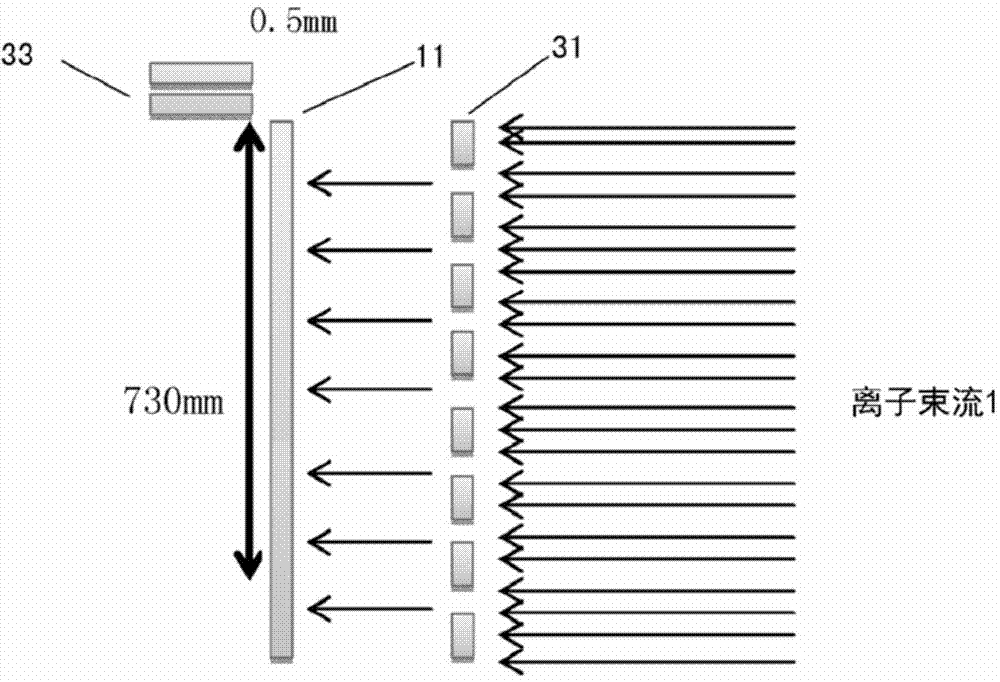

[0072] Such as image 3 As shown, the ion beam 1 to be measured (ion beam implanter model Magic-I70, manufacturer MES-Afty company, ion source BF3, voltage 80KeV) is irradiated on the substrate through the ion beam penetration unit 31 The glass substrate 11 is placed on the unit, and the current on the glass substrate 11 is measured by the current collection unit (included in the ion beam implanter) 33, and the glass substrate 11 placed on the substrate placement unit is connected with the ion beam The flow through the unit 31 is parallel.

[0073] The ion beam passing unit 31 is a graphite jig, the width of the slits is 8 mm, and the distance between the slits is 100 mm.

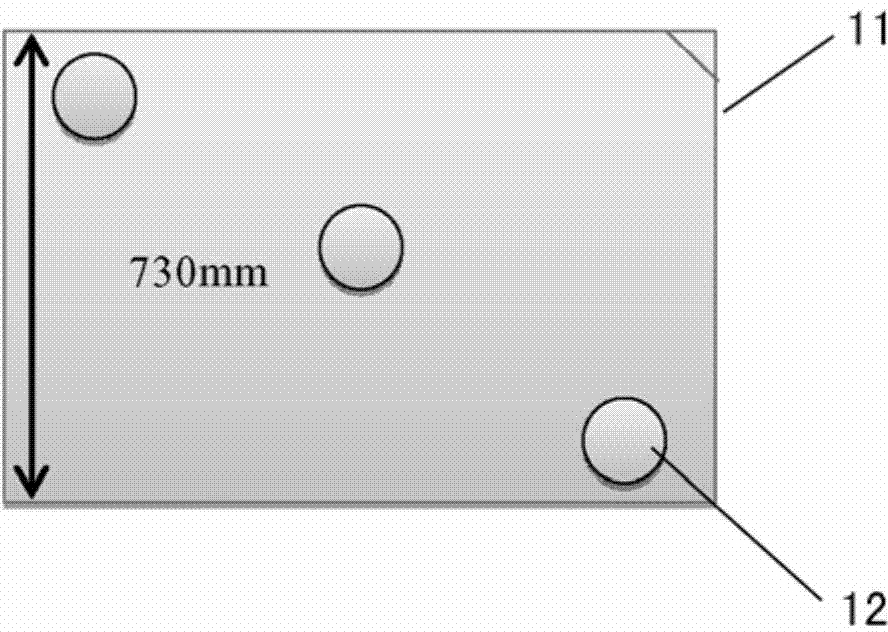

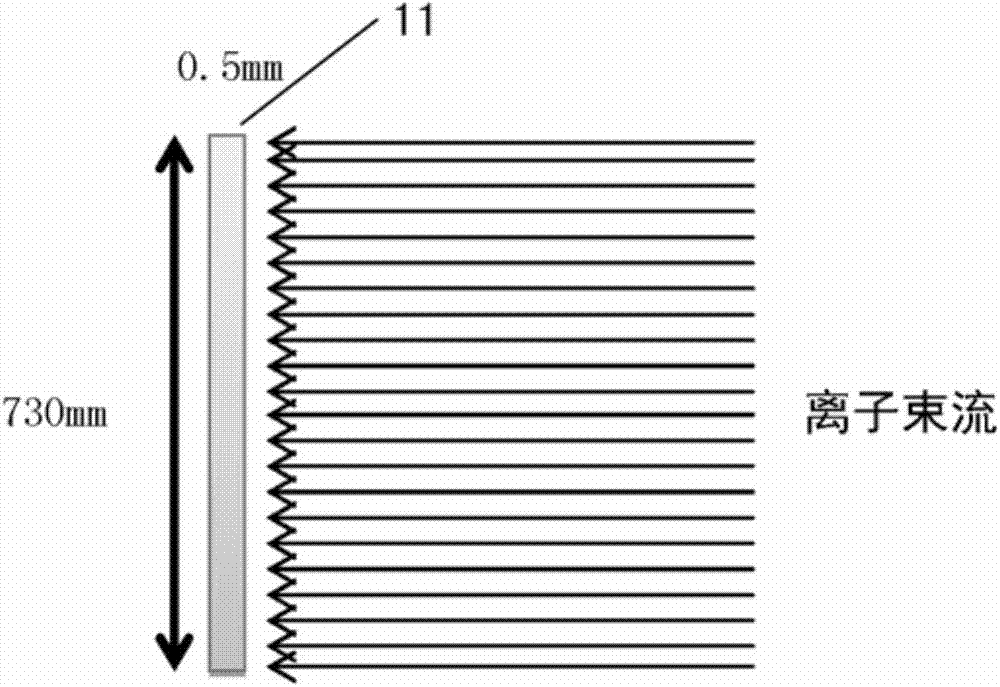

[0074] The size of the glass substrate 11 is 730mm*920mm.

[0075] Moreover, the distance between the ion beam current passing unit 31 and the glass substrate 11 is 1.5 meters.

[0076] The measured results are as Figure 4 shown in Figure 4 Among them, the horizontal axis represents the ion beam curr...

Embodiment 2

[0079] Such as Figure 5 As shown, the ion beam current 2 to be measured (ion beam implanter model Magic-I70, manufacturer MES-Afty company, ion source BF3, voltage 80KeV) passes through the ion beam current penetration unit 31, and shoots at The glass substrate 11 placed on the substrate placement unit, and the current on the glass substrate 11 is measured by the current collection unit (included in the ion beam implanter) 33, and the glass substrate 11 placed on the substrate placement unit is connected to the The ion beam flows through the unit 31 in parallel.

[0080] The ion beam passing unit 31 is a graphite jig, the width of the slits is 8 mm, and the distance between the slits is 200 mm.

[0081] And, the size of the glass substrate 11 is 730mm*920mm

[0082] In addition, the ion beam flows through the unit 31 , and the distance between the ion beam and the glass substrate 11 is 1.5 meters.

[0083] The measured results are as Figure 6 shown in Figure 6 , the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com