Solid oxide fuel cell

A solid oxide and fuel cell technology, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of increased difficulty in battery sealing, low thermal efficiency of batteries, insufficient energy recovery, etc., to reduce air leakage Risk, high power generation efficiency, and the effect of increasing reaction contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

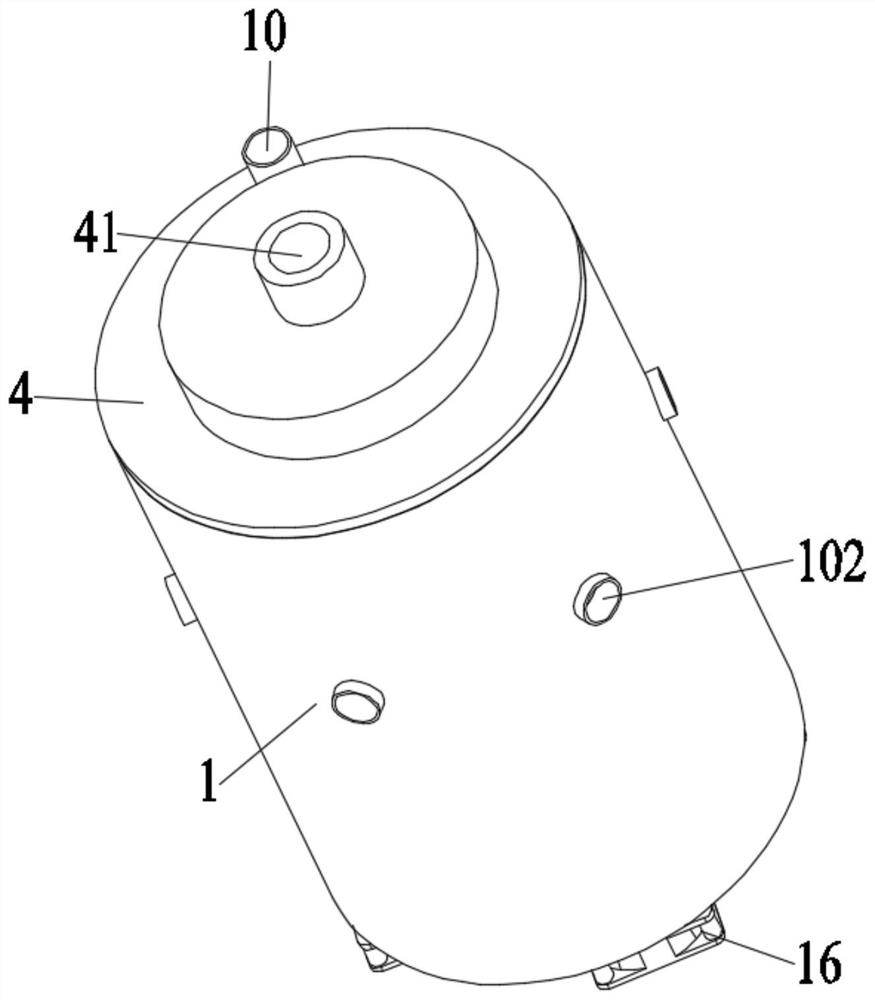

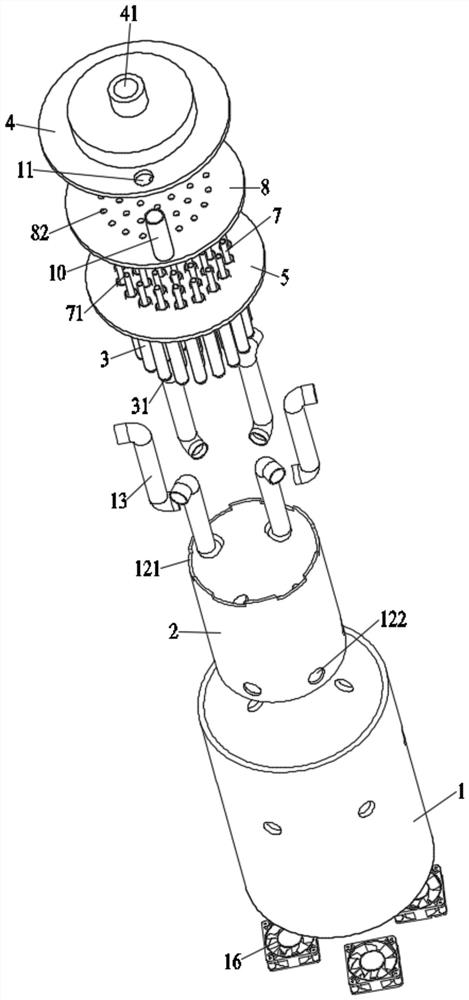

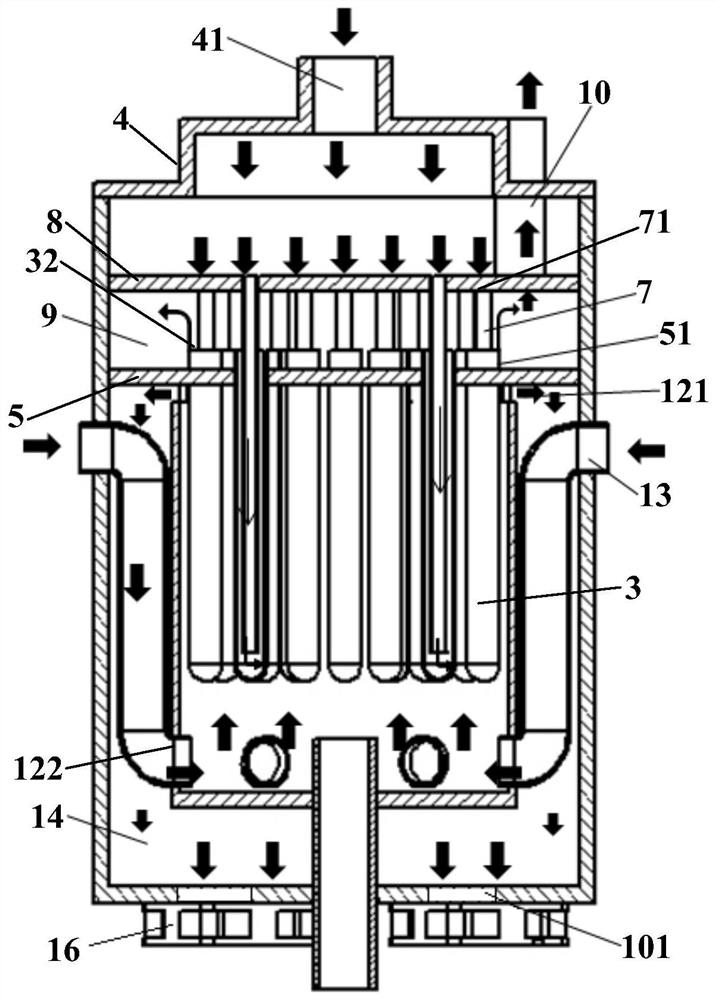

[0026] Embodiment 1: A solid oxide fuel cell, including an outer casing 1, an inner casing 2, several battery tubes 3 and a top cover 4 with a gas inlet 41, and several cathode rows are opened at the bottom of the outer casing 1 Air port 101, the top cover 4 is installed on the top of the outer casing 1, one end of the battery tube 3 is a sealed end 31, and the other end is an open end 32, and several battery tubes 3 are respectively embedded in a battery tube fixing plate 5 In the corresponding first through hole 51, an inner cavity 6 is formed between the inner casing 2 and the battery tube fixing plate 5 located at the top of the inner casing 2, and the sealed ends 31 of several battery tubes 3 are located in the inner casing 2. 2, one end of a plurality of ventilation tubes 7 with openings 71 at both ends is respectively embedded in the bottom of the battery tube 3, and the other ends of the plurality of ventilation tubes 7 are respectively embedded in a second through hole...

Embodiment 2

[0033]Embodiment 2: A solid oxide fuel cell, including an outer casing 1, an inner casing 2, several battery tubes 3 and a top cover 4 with a gas inlet 41, and several cathode rows are opened at the bottom of the outer casing 1 Air port 101, the top cover 4 is installed on the top of the outer casing 1, one end of the battery tube 3 is a sealed end 31, and the other end is an open end 32, and several battery tubes 3 are respectively embedded in a battery tube fixing plate 5 In the corresponding first through hole 51, an inner cavity 6 is formed between the inner casing 2 and the battery tube fixing plate 5 located at the top of the inner casing 2, and the sealed ends 31 of several battery tubes 3 are located in the inner casing 2. 2, one end of a plurality of ventilation tubes 7 with openings 71 at both ends is respectively embedded in the bottom of the battery tube 3, and the other ends of the plurality of ventilation tubes 7 are respectively embedded in a second through hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com