Novel AC generator stator wire rod transposition method

A technology of alternator and stator bar, used in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of increased circulating current loss, reduce circulating current and circulating current loss, have great practical significance, and reduce circulating current. The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

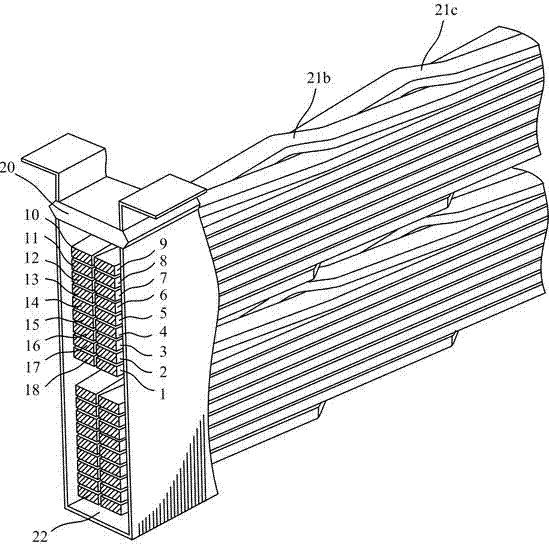

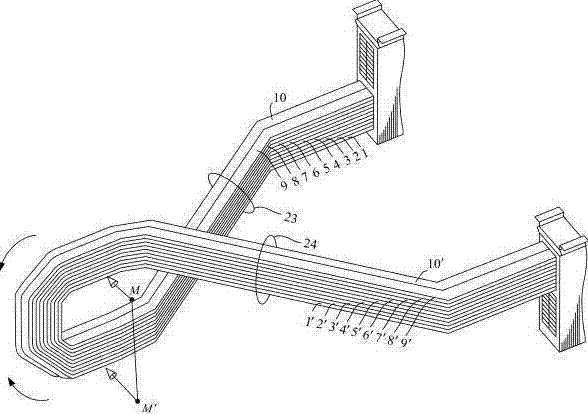

[0032] The specific implementation manner of the patent of the present invention will be further described below in conjunction with the accompanying drawings.

[0033] Such as figure 1 As shown, the basic steps of transposition of strands in the groove are as follows:

[0034] (1) The strands are arranged horizontally in several rows. The present invention takes two rows of strands as an example, and each layer of wire rods contains 18 strands;

[0035] (2) The left row of strands and the right row of strands extend along the traveling direction of the strands respectively at different angles. The groove bottom direction (22) is inclined downward;

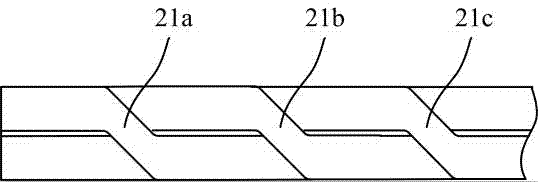

[0036] (3) The first strand (10) at the top of the left row passes through the first transposition bend (21a) along the direction of travel to the top of the first strand (9) at the top of the right row, and the inclination angle changes until it is in line with The right row of strands travels in the same direction;

[0037] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com