Stamping machine with automatic rotary feeding function

A technology of automatic rotating and stamping machine tools, applied in the direction of manufacturing tools, feeding devices, positioning devices, etc., can solve the problems of inconvenient maintenance, high cost, complex structure, etc., and achieve convenient maintenance, low cost, continuous automatic feeding and receiving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

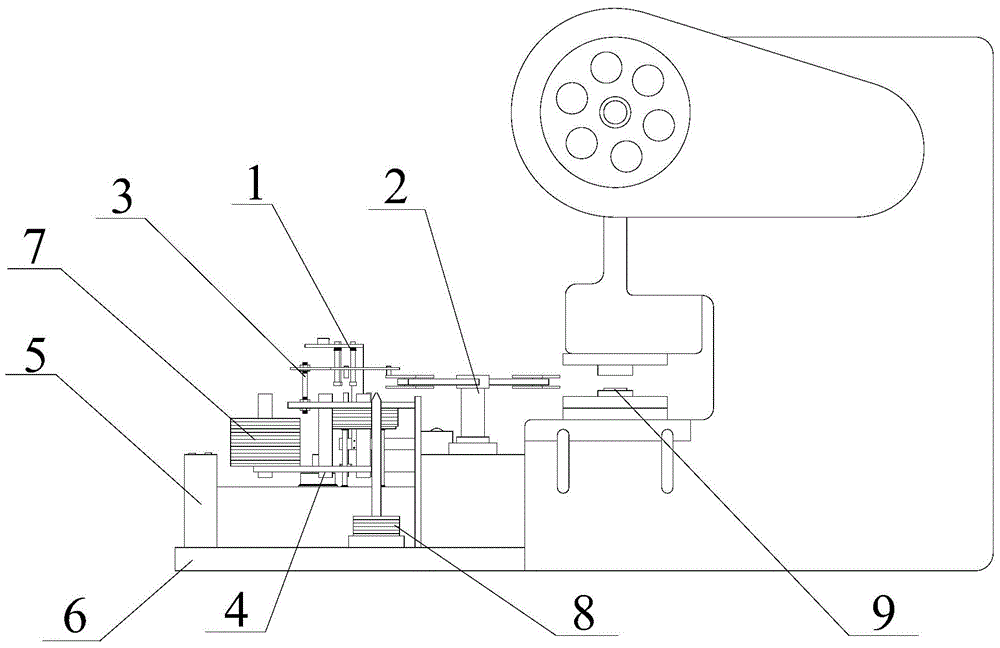

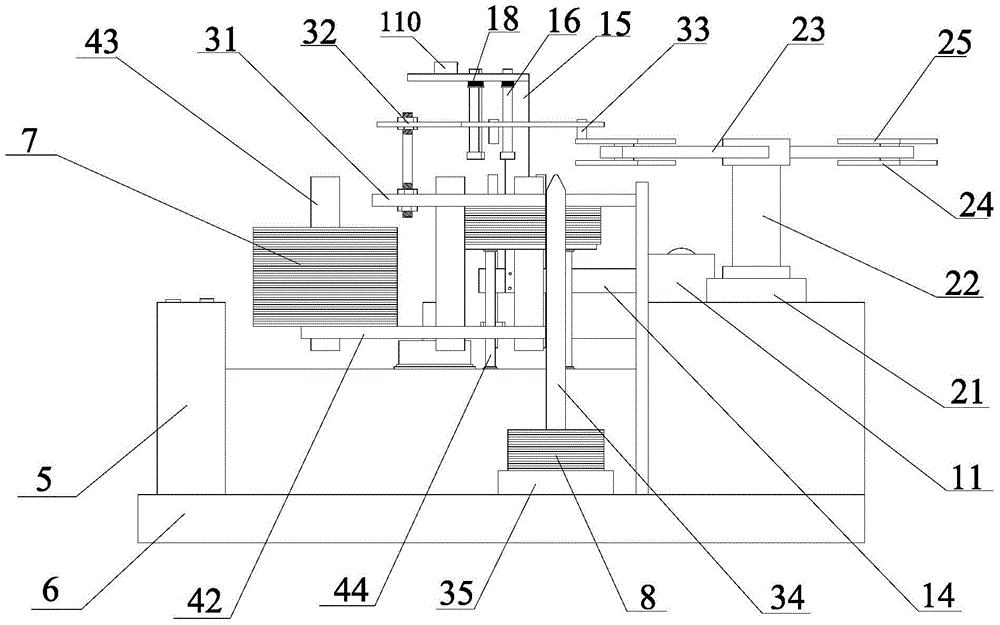

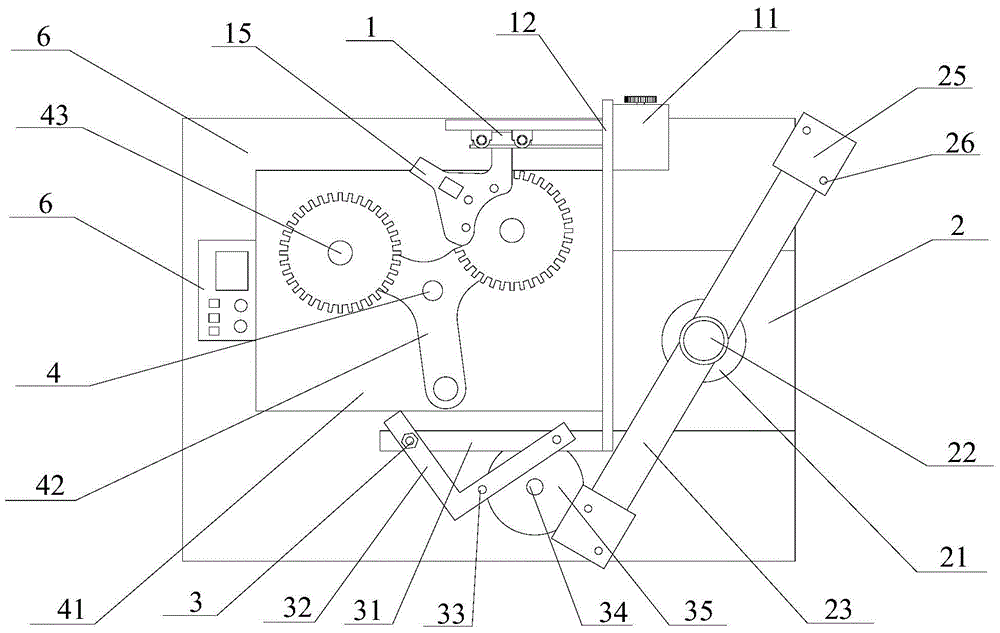

[0026] like Figure 1-4 As shown, the stamping machine tool with automatic rotation feeding function includes a punching machine tool, and the punching machine tool includes an upper die and a lower die, and also includes an automatic rotating feeding manipulator, and the automatic rotating feeding manipulator includes a retrieving device 1, a feeding Device 2, material receiving device 3, material retrieving rack 4, control cabinet 5 and base 6;

[0027] The reclaiming device 1 comprises a gear transmission case 11, a frame-shaped support 12, a movable guide rail 13, a fixed block 14, a connecting plate 15, an air pipe 16 and a vacuum suction cup 17; On the board, the frame-shaped support 12 is fixed on the base 6, the movable guide rail 13 is installed on the inner wall of the left side plate of the frame-shaped support 12, the fixed block 14 is fixed on the movable guide rail 13, and Connected with the gear transmission box 11, the vacuum chuck 17 is installed under the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com