Waste automatic discharge device and discharge method

A technology for automatic discharge and waste, applied in the field of stamping dies, can solve the problems of reduced production efficiency of stamping processing, and the waste cannot be discharged smoothly, so as to achieve the effect of improving production efficiency, shortening development cycle and reducing development cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

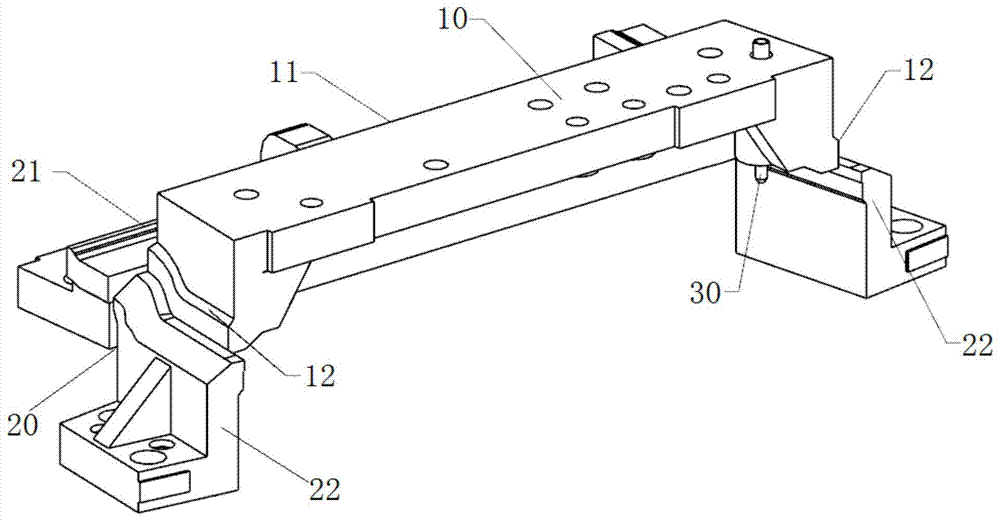

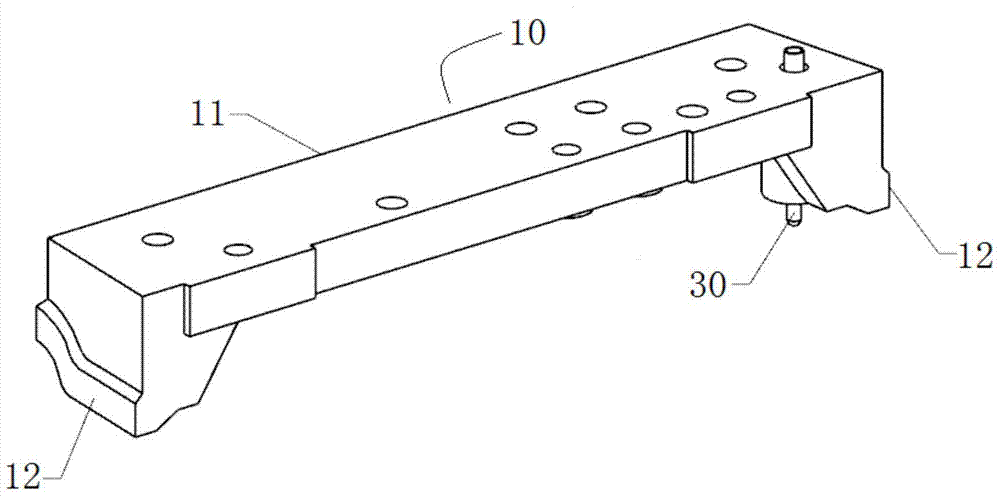

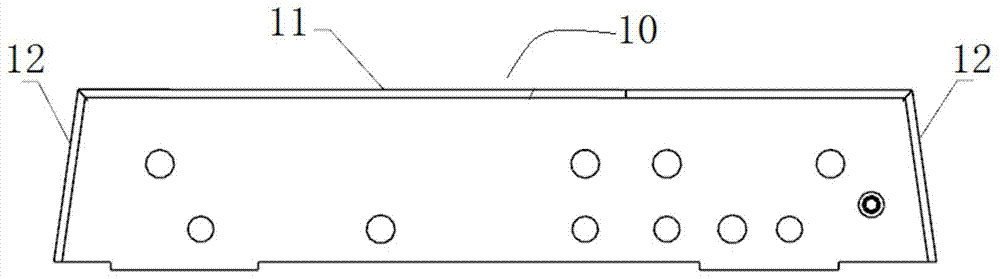

[0025] Such as figure 1 As shown, a waste automatic discharge device described in this embodiment includes an upper die trimming insert 10 and a lower die insert set 20 matched with the upper die trimming insert 10, the upper die trimming The edge insert 10 includes a horizontally placed upper plate 11 and two opposite upper mold waste knives 12 positioned on the side of the upper plate 11, and the lower mold insert group 20 includes a lower mold trimming located below the upper plate 11 The insert 21 and the lower mold scrap knife 22 that is positioned at the side of the lower mold trimming insert 21 and is opposite to the upper mold scrap knife 12, and the edge of the upper mold scrap knife 12 is aligned with the lower mold scrap knife 22 The edge is matched for cutting waste, the angle formed by the edge of the upper die waste knife 12 and the edge of the upper plate 11 and the edge of the lower die waste knife 22 and the edge of the lower die trimming insert 21 The angles...

Embodiment 2

[0032] The present invention also provides a waste material discharge method using any one of the waste automatic discharge devices described above, including the following steps: Step S1: the upper mold trimming insert 10 moves vertically downward until the upper mold waste material The knife 12 cooperates with the waste knife 22 of the lower mold to complete the waste cutting; step S2: the upper mold trimming insert 10 continues to move downward and automatically discharges the waste when it stops; step S3: the upper mold trimming insert After the block 10 moves vertically upwards until it stops again, it repeats from step S1.

[0033] In the waste material discharging method described in the present invention, the waste material automatic discharge device described in any one of the above is used, since the upper mold trimming insert 10 is arranged on the upper mold base, and the lower mold insert group 20 is arranged on the lower mold base In the above, the upper mold base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com