Amphibious Vehicle Lift Wheel Drag Reduction Device

A technology of drag reduction device and lift wheel, which is applied in mechanical gear transmission, transportation and packaging, hydrodynamic characteristics/hydrostatic characteristics, etc. The effect of increasing the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

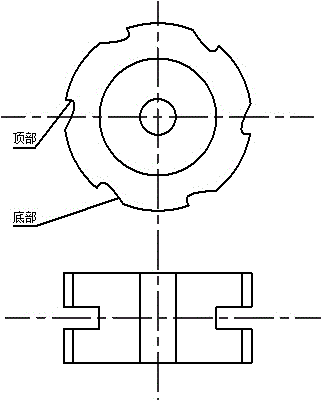

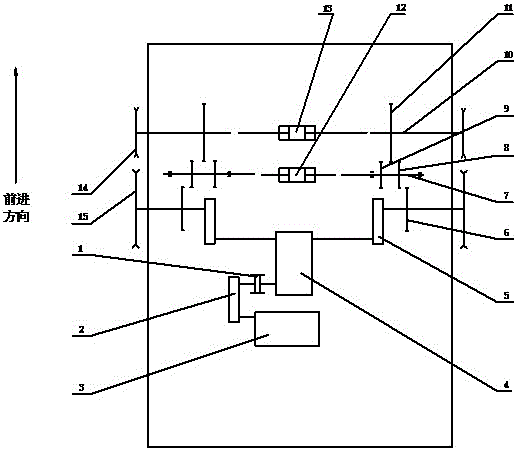

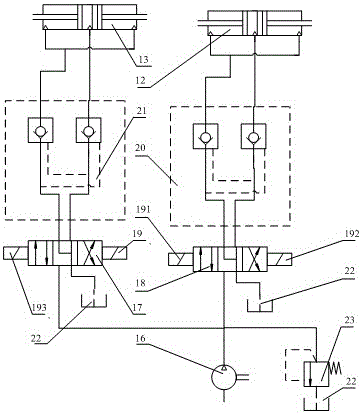

[0019] Such as Figure 1 to Figure 7 As shown, a lift wheel drag reduction device for amphibious vehicles includes two lift wheels 14, a gear transmission mechanism, and a hydraulic control system; The wheel side reducer 5 is connected, and the drive shaft gear 6 is installed on the output shaft of the wheel side reducer 5, and the driving wheel 15 is coaxially installed; the gear transmission mechanism includes two lift wheel shaft gears 11, two lift wheel shafts 10 , two intermediate shafts 7, two intermediate shaft outer end gears 8, two intermediate shaft inner end gears 9, two driving shaft gears 6; two lifting force wheel shaft gears 11 are installed on the two lift wheel shafts 10, and simultaneously Two lifting wheels 14 are installed on the shaft, and an intermediate shaft outer end gear 8 and an intermediate shaft inner end gear 9 are respectively installed on each intermediate shaft 7; the hydraulic control system includes a hydraulic pump 16, the first valve seat 1...

Embodiment 2

[0023] This embodiment is basically the same as Embodiment 1, especially in that, see Figure 1-Figure 7 When the amphibious vehicle enters the water from the land, the third electromagnetic coil 192 is activated to connect the right position of the first valve seat 18 to the hydraulic circuit, the right one-way valve of the first hydraulic lock 20 is connected, and the piston rod of the double-acting middle hydraulic cylinder 12 is extended. Out, the gear 8 at the outer end of the intermediate shaft meshes with the gear 6 of the drive shaft, and at the same time, the inner gear 9 of the intermediate shaft meshes with the gear 11 of the lift wheel shaft, and the lift wheel rotates. Body balance, start the first electromagnetic coil 19, the right position of the second valve seat 17 is connected to the hydraulic circuit, the right one-way valve of the second hydraulic lock 21 is connected, and the double-acting lift wheel hydraulic cylinder 13 enters the rodless cavity, double-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com