Belt material scraping device

A scraper and scraping technology, which is used in cleaning devices, transportation and packaging, conveyor objects, etc., can solve the problems of low work efficiency, inconvenient maintenance, and high maintenance costs, to improve work efficiency, reasonable design structure, The effect of saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

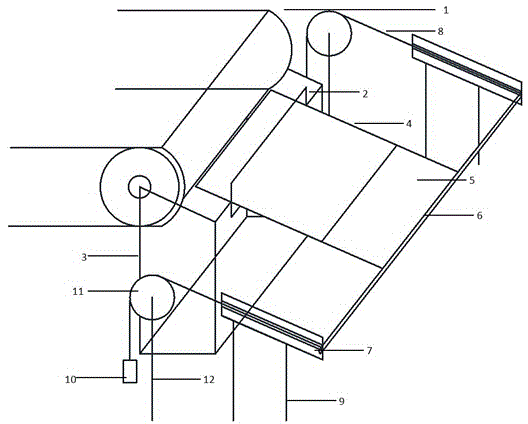

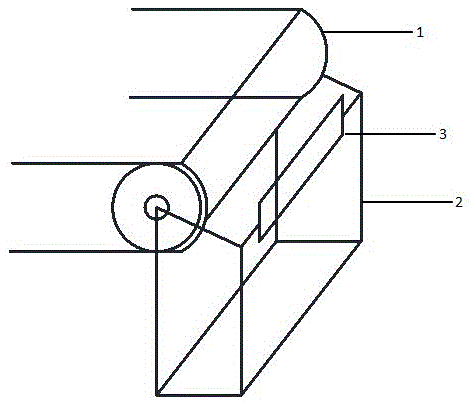

[0012] Example as figure 1 Shown, a kind of belt scraper, described belt scraper is arranged on the right end of belt conveyor 1 head, and described belt conveyor head comprises driving roller, the belt that is located on described driving roller and Belt conveyor bracket, the belt scraper includes a scraper leather positioning sleeve 2, a scraper leather positioning sleeve bracket 3, and a scraper leather 4, and the scraper leather positioning sleeve 2 is welded on the scraper leather positioning sleeve bracket 3, and set at the right end of the head of the belt conveyor 1, such as figure 2As shown; the scraper leather 4 passes through the scraper leather positioning sleeve 2, and is in contact with the belt located at the right end of the driving roller; the right end of the scraper leather 4 is fixed by two positioning splints 5 up and down, The right end of the positioning splint 5 is provided with a pipe body 6, and two ends of the pipe body 6 are symmetrically provided...

Embodiment 2

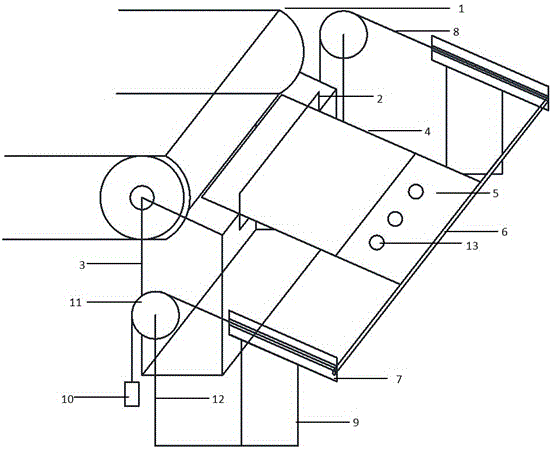

[0014] Example two such as image 3 Shown, a kind of belt scraper, described belt scraper is arranged on the right end of belt conveyor 1 head, and described belt conveyor head comprises driving roller, the belt that is located on described driving roller and Belt conveyor bracket, the belt scraper includes a scraper leather positioning sleeve 2, a scraper leather positioning sleeve bracket 3, and a scraper leather 4, and the scraper leather positioning sleeve 2 is welded on the scraper leather positioning sleeve bracket 3, and is arranged at the right end of the head of the belt conveyor 1; the scraper leather 4 passes through the scraper leather positioning sleeve 2, and contacts with the belt located at the right end of the driving roller; the scraper The right end of the material skin 4 is fixed by two positioning splints 5 up and down, the right end of the positioning splint 5 is provided with a pipe body 6, and the two ends of the pipe body 6 are symmetrically provided w...

Embodiment 3

[0020] Embodiment 3, a belt scraper, the belt scraper is arranged at the right end of the head of the belt conveyor 1, the head of the belt conveyor includes a driving roller, a belt arranged on the driving roller And the belt conveyor bracket, the belt scraper includes a scraper leather positioning sleeve 2, a scraper leather positioning sleeve bracket 3, and a scraper leather 4, and the scraper leather positioning sleeve 2 is welded on the scraper leather positioning sleeve on the bracket 3, and is arranged at the right end of the head of the belt conveyor 1; the scraper leather 4 passes through the scraper leather positioning sleeve 2, and is in contact with the belt located at the right end of the driving roller; the The right end of the scraper skin 4 is fixed by two upper and lower positioning splints 5, the right end of the positioning splint 5 is provided with a pipe body 6, and the two ends of the pipe body 6 are symmetrically provided with two plates 7, and the plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com